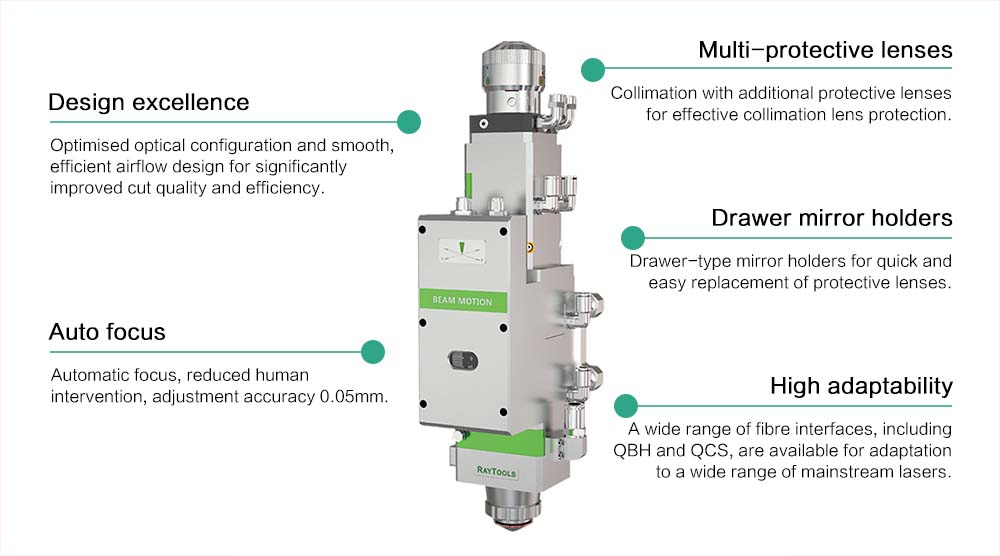

Features of raytools laser cutting head

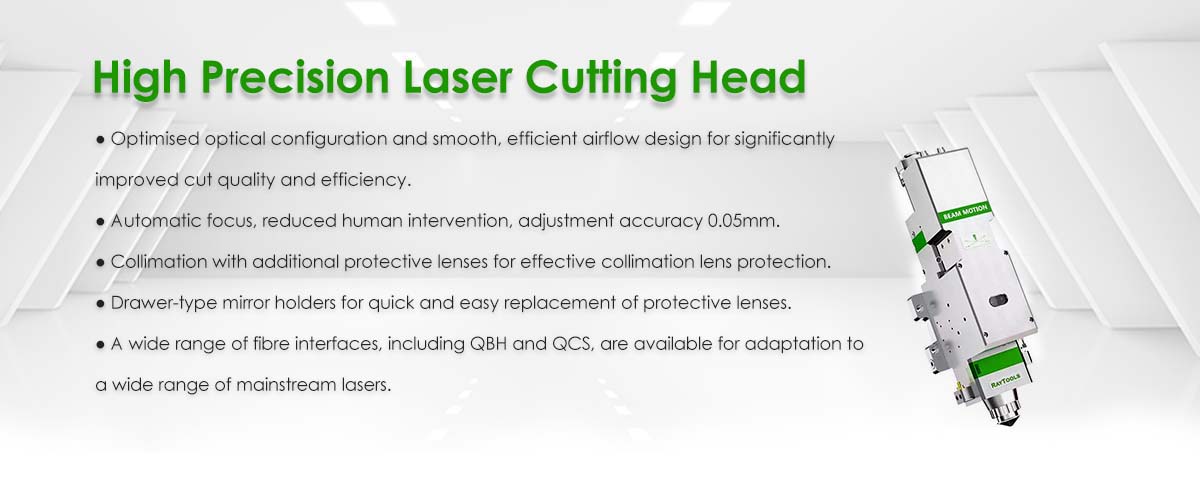

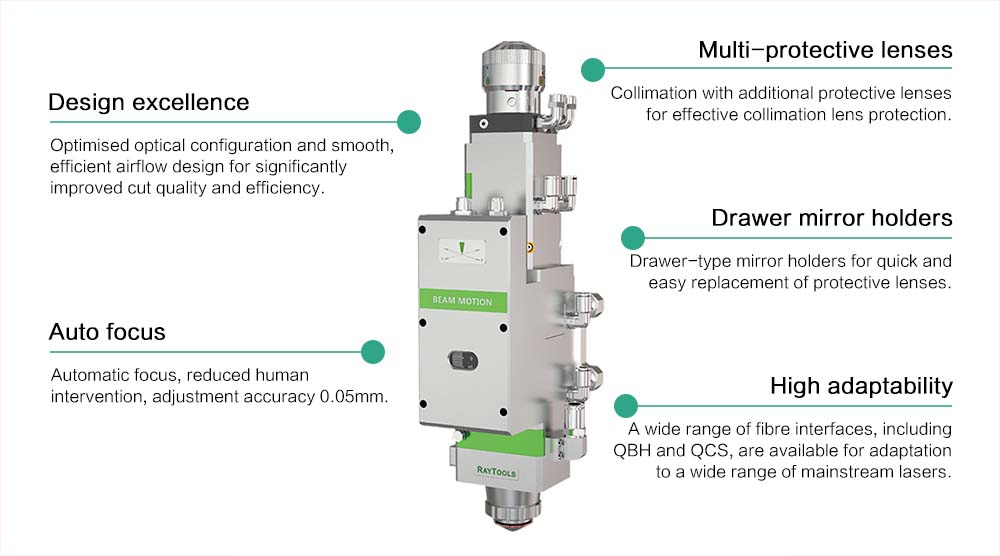

1. Optimized optical configuration and smooth and efficient airflow design.

2. Knob type focus adjustment, fine and flexible adjustment, the adjustable range is 10-15mm, and the adjustment accuracy is 0.05mm.

3. A protective mirror is added to the collimating mirror, which can effectively prevent the damage caused by dust falling into the collimating mirror.

4. The drawer-type lens holder is used, which makes the replacement of the protective lens, collimating lens and focusing lens quick and easy.

5. The nozzle assembly has a built-in annular air cooling and side blowing structure, which is conducive to cutting high-reflective materials and sputtering explosion-proof holes on thick plates.

6. Both the collimating lens and the focusing lens have a water-cooled structure, so that they can withstand a maximum power of 6KW.

7. Composite lenses can be used for both collimation and focusing to obtain the best optical quality and cutting effect.

8. With a variety of fiber interfaces, it can be adapted to various fiber lasers.

Structure function of raytools laser cutting head

The laser head consists of four basic units such as collimation module, focus drive module, protection mirror module and nozzle.

1. Collimation module: to complete the fiber collimation function, the incident laser collimated into a parallel beam and has a centering function.

2. Focusing drive module: focus the collimated beam into a high power density converging beam, and achieve automatic adjustment of the focus position through the drive device.

3. Protective lens module: The protective lens can protect the focusing lens from the damage of returning slag and prolong the service life of the focusing lens.

4. Nozzle module: guide the converging beam to the processing workpiece and generate high speed airflow to jet the cutting slit to complete high quality cutting.

Parameters of raytools laser cutting head

Laser head |

Rated power | Up to 4KW |

Focal length | 100mm、125mm、150mm、200mm |

Clear aperture | 25mm |

Nozzle diameter | 0.5-3mm |

Nozzle Specifications | Single layer, composite, porous, shower type, customized |

Cutting pressure | ≤20Bar |

Focus range | -5mm-+8mm |

Weight | 1.5KG |

Collimator |

Collimation focal length | 60mm、75mm、100mm |

Clear aperture | 25mm |

Fiber optic interface | QBH、QD、LLK-B、PIPA-Q |

Height sensor |

Sensing distance range (recommended 1mm) | 0.2mm-8mm |

Calibration | Automatic calibration |

Reaction time | <1ms |

Temperature stability | 0°~45°,±5° |

Power requirements | 24V |

Output (linear curve or optimized curve) | 0~10V analog |