All lenses of the company are made of imported crystal materials through cutting, grinding, polishing, coating and other processes. Our company has made every effort to provide the most valuable products and the highest quality services to all customers around the world. At the same time, it can customize various specifications to protect the lenses for customers.

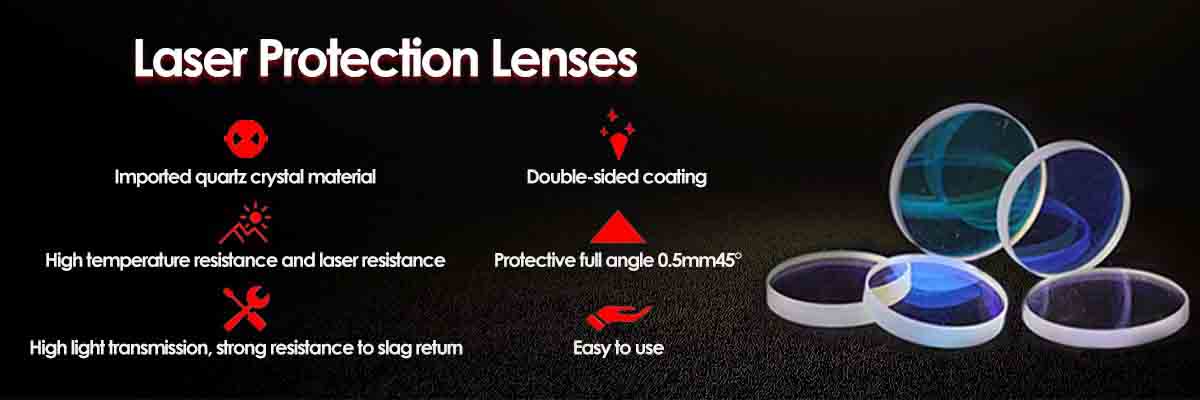

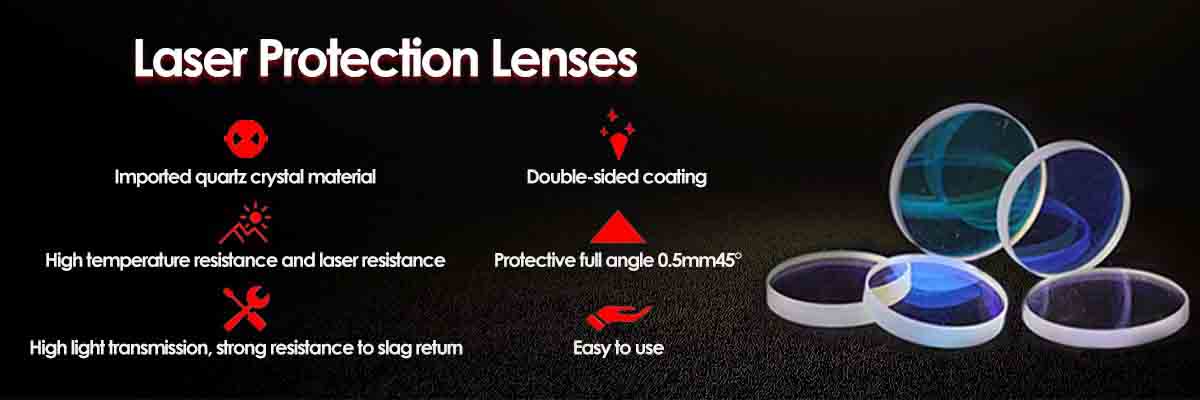

Features of fiber laser protective lens

1. No chipping, not easy to crack

Imported quartz crystal material, uniform texture, high mechanical strength, high temperature and pressure resistance, the lens is not easy to crack the edge.

2. High temperature resistance, strong laser resistance

The lenses are made of excellent substrates with excellent optical properties and good thermal stability, and are processed with high precision through cutting, polishing and grinding processes. The lenses are high temperature resistant and have strong laser resistance.

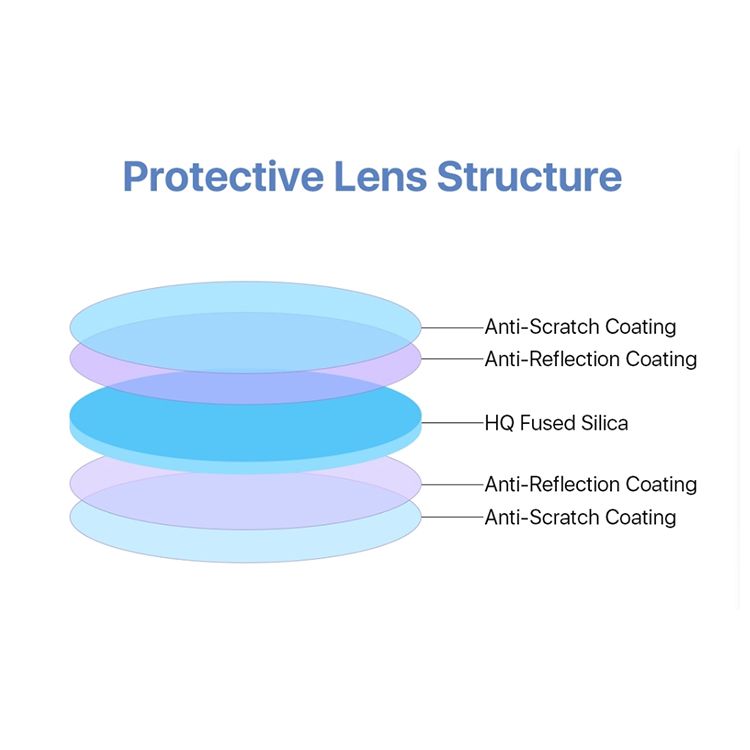

3. High transmittance, strong anti-slag

Both sides of the lens are coated with a high damage threshold transmissivity film to reduce the loss caused by reflection, and the coating makes it safe from splashes and other hazards and has a long life.

4. Safe and easy to use, no hand injury

Humanized 45°protective full-angle design is easy to apply and does not hurt your hands.

Hot specifications of fiber laser protective lens

P/N | Diameter | Thickness | Wavelength |

JGS1-D20-T2 | 20 | 2 | 1010-1090nm |

JGS1-D20-T3 | 20 | 3 | 1010-1090nm |

JGS1-D20-T5 | 20 | 5 | 1010-1090nm |

JGS1-D22.35-T4 | 22.35 | 4 | 1010-1090nm |

JGS1-D25-T2 | 25 | 2 | 1010-1090nm |

JGS1-D25-T3 | 25 | 3 | 1010-1090nm |

JGS1-D25.4-T4 | 25.4 | 4 | 1010-1090nm |

JGS1-D25.4-T5 | 25.4 | 5 | 1010-1090nm |

JGS1-D27-T4 | 27 | 4 | 1010-1090nm |

JGS1-D28-T4 | 28 | 4 | 1010-1090nm |

JGS1-D30-T1.5 | 30 | 1.5 | 1010-1090nm |

JGS1-D30-T5 | 30 | 5 | 1010-1090nm |

JGS1-D32-T4 | 32 | 4 | 1010-1090nm |

JGS1-D34-T3 | 34 | 3 | 1010-1090nm |

JGS1-D34-T5 | 34 | 5 | 1010-1090nm |

JGS1-D35-T1.5 | 35 | 1.5 | 1010-1090nm |

JGS1-D35-T4 | 35 | 4 | 1010-1090nm |

JGS1-D36-T5 | 36 | 5 | 1010-1090nm |

JGS1-D37-T7 | 37 | 7 | 1010-1090nm |

JGS1-D38-T2 | 38 | 2 | 1010-1090nm |

We can provide lenses for any wavelength according to customer requirements. For other wavelengths, diameters and thicknesses of lenses, we can also produce them on request.

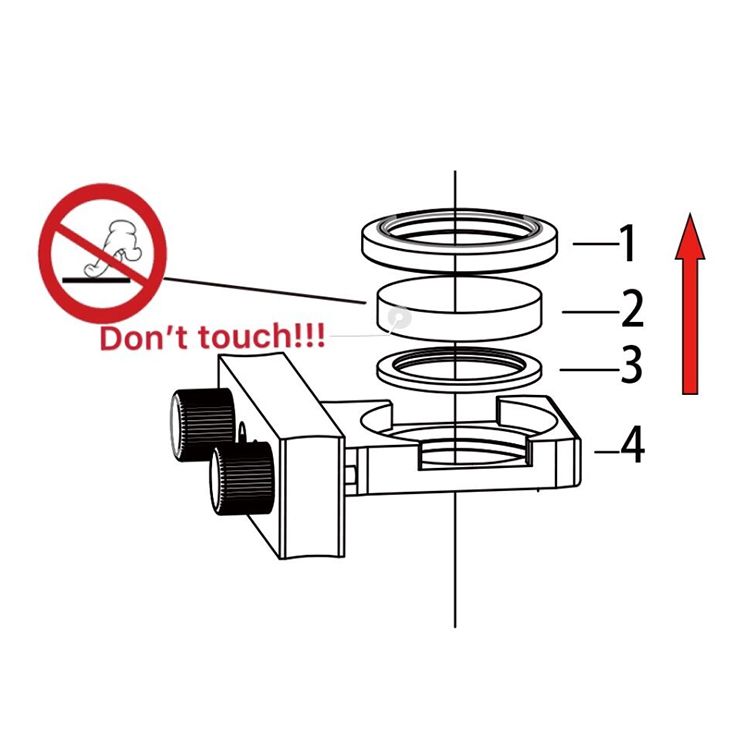

During the installation and cleaning of protective lenses, any sticky substances, even oil droplets printed on nails, etc., will increase the absorption rate of the lens and shorten the service life. Therefore, lens cleaning should not be neglected

1. When installing, you must wear gloves and do not leave any fingerprints.

2. Do not scratch the lens surface with anything.

3. When holding the lens, please grasp the edge of the lens with both hands, and do not touch the mirror surface.

4. Clean the lens with a clean tissue, paper and optical grade solvent

The protective lens of laser equipment is a consumable. If the cleanliness is still not high after repeated cleaning, please pay attention to replace it to ensure the processing efficiency of the laser equipment and avoid delays in production.

Parameters of fiber laser protective lens

Product name | Laser protection lens |

Material | Imported quartz |

Wavelength | 1064nm |

Diameter range | 18-150mm |

Diameter Tolerance | ±0.1mm |

Thickness range | 1-10mm |

Thickness Tolerance | ±0.1mm |

Transmittance | 99.99% |

Clear aperture | >80% |

Surface finish | 20/40 |

Parallelism | <0.01mm |