Design Principle of Laser Focusing Lens

Laser focusing lens usually adopts the principle of refraction or reflection, through the appropriate curvature and material manufacturing, to realize the focusing and adjustment of the laser beam. A good quality laser focusing lens can improve the performance and stability of the laser system.

Key performance indicators

● Focusing and scanning range, the focus position depends on both the focal length and the declination angle.

● The scanning range is proportional to the focal length of the scene. After focusing, the spot diameter is proportional to the focal length. That is, when the scanning area reaches a certain level, the larger the spot diameter is.

The role of laser focusing mirror

1. Improvement of laser beam focusing effect

The laser focusing lens can focus the laser beam to a very small point and improve the energy density of the laser beam, thus playing an important role in laser processing, laser cutting and other fields.

2. Adjustment of laser spot size and shape

By replacing the focusing lens with different focal lengths, the size and shape of the laser spot can be adjusted to meet different processing requirements and improve processing accuracy and efficiency.

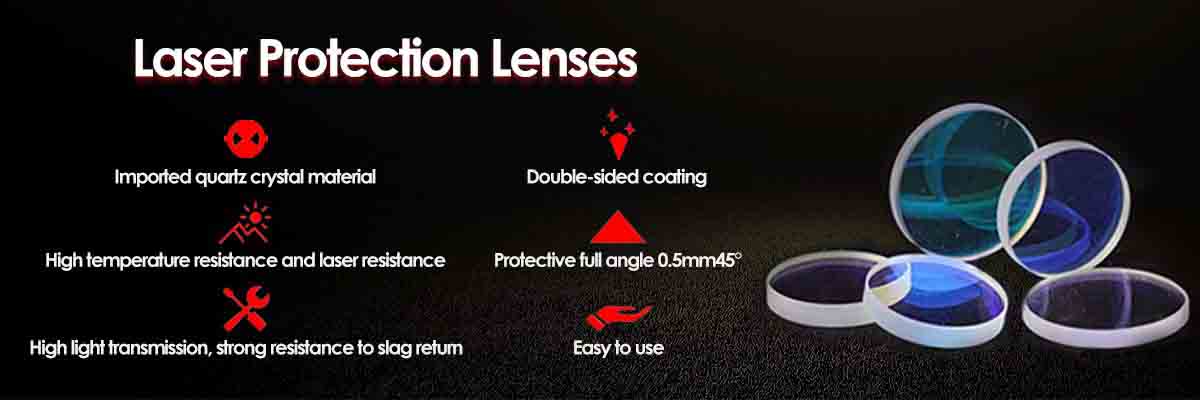

3. Improve the stability of laser system

The high quality material and precision processing technology of Laser Focus Lens can improve the stability and durability of the laser system, and ensure the stable operation of the laser device for a long time.

4. Expanding the field of laser application

With the continuous development of laser technology, the application fields of Laser Focus Lens are also expanding, covering laser processing, medical equipment, communications and other fields.

5. Enhance the efficiency of laser processing

With high quality Laser Focus Lens, it can improve the efficiency and quality of laser processing, realize finer processing and cutting, and meet the needs of different industries.

6. Ensure the performance of laser device

As a key component of laser components, the quality and performance of Laser Focus Lens directly affects the working effect and stability of the whole laser system.

Parameters of laser focus lens

Specification |

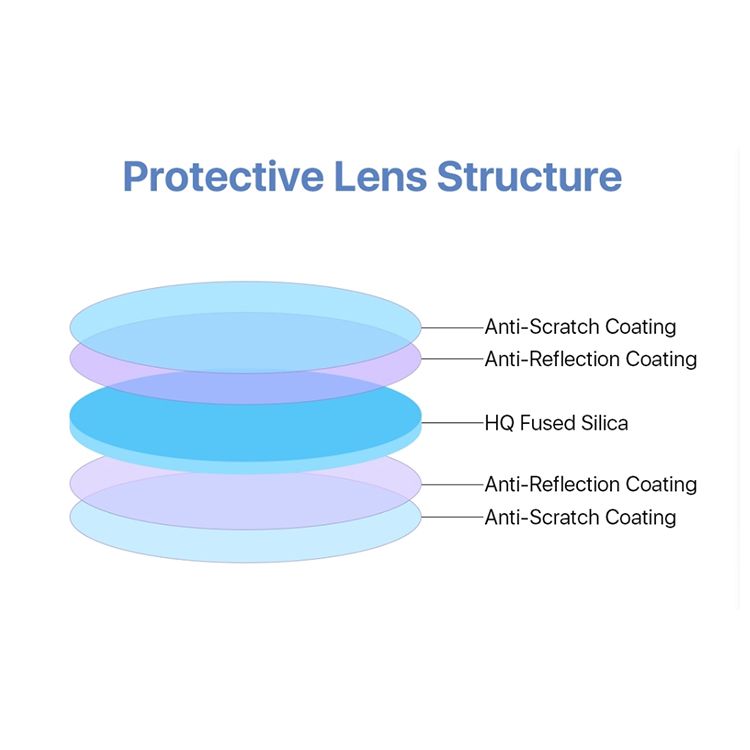

Material | Fused Silica |

Diameter Tolerance | +.000", -.005" |

Thickness Tolerance | ±.005" |

Surface Figure | Plane: 1/0.5 Curve: 3/1 (Power/irregularity) |

Centration | <.001" |

Focal Length Tolerance | <1.0% |

Surface Quality | <10-5 scratch-dig Laser Finish |

Spectral Performance |

Standard AR Coating type Both Sides @ 1070nm (AR Coating) |

Absorption | <30PPM |

Transmittance | >99.9% |