Features of laser cutter lens

1. Imported quartz crystal material, uniform texture, high mechanical strength, high temperature resistance, high pressure, the lens is not easy to chipping edge cracking.

2. Choose excellent substrate, excellent optical performance, good thermal stability, and after cutting piece, polishing, polishing and other high-precision process of fine processing. The lenses are high temperature resistant and have strong laser resistance.

3. High light transmittance, strong anti-slag, high anti-laser damage threshold.

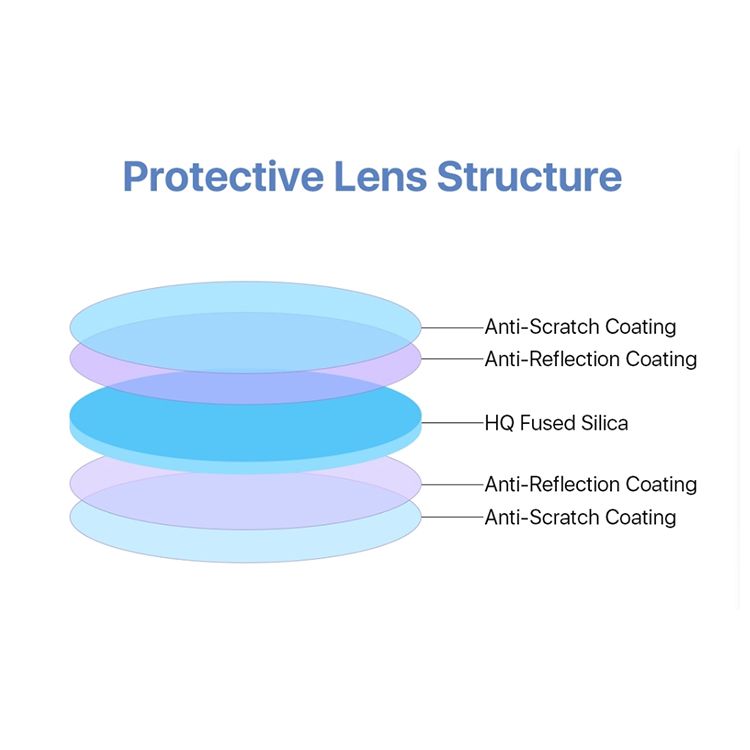

4. Both sides of the lens are coated with a high damage threshold transmissive film to reduce the loss caused by reflection, and the coating makes it safe from splashes and other hazards and has a long life.

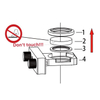

5. 45° protective full-angle design for easy application and no hand injury.

Hot specifications of laser cutter lens

P/N | Diameter | Thickness | Wavelength |

JGS1-D20-T2 | 20 | 2 | 1010-1090nm |

JGS1-D20-T3 | 20 | 3 | 1010-1090nm |

JGS1-D20-T5 | 20 | 5 | 1010-1090nm |

JGS1-D22.35-T4 | 22.35 | 4 | 1010-1090nm |

JGS1-D25-T2 | 25 | 2 | 1010-1090nm |

JGS1-D25-T3 | 25 | 3 | 1010-1090nm |

JGS1-D25.4-T4 | 25.4 | 4 | 1010-1090nm |

JGS1-D25.4-T5 | 25.4 | 5 | 1010-1090nm |

JGS1-D27-T4 | 27 | 4 | 1010-1090nm |

JGS1-D28-T4 | 28 | 4 | 1010-1090nm |

JGS1-D30-T1.5 | 30 | 1.5 | 1010-1090nm |

JGS1-D30-T5 | 30 | 5 | 1010-1090nm |

JGS1-D32-T4 | 32 | 4 | 1010-1090nm |

JGS1-D34-T3 | 34 | 3 | 1010-1090nm |

JGS1-D34-T5 | 34 | 5 | 1010-1090nm |

JGS1-D35-T1.5 | 35 | 1.5 | 1010-1090nm |

JGS1-D35-T4 | 35 | 4 | 1010-1090nm |

JGS1-D36-T5 | 36 | 5 | 1010-1090nm |

JGS1-D37-T7 | 37 | 7 | 1010-1090nm |

JGS1-D38-T2 | 38 | 2 | 1010-1090nm |

We can provide lenses for any wavelength according to customer requirements. For other wavelengths, diameters and thicknesses of lenses, we can also produce them on request.

Although the lens of the laser cutting machine is a wearing part, in order to improve its utilization rate and reduce production costs, the lens can be cleaned regularly to achieve the purpose of reuse.

When we carry out lens maintenance, we need to pay attention to the following points:

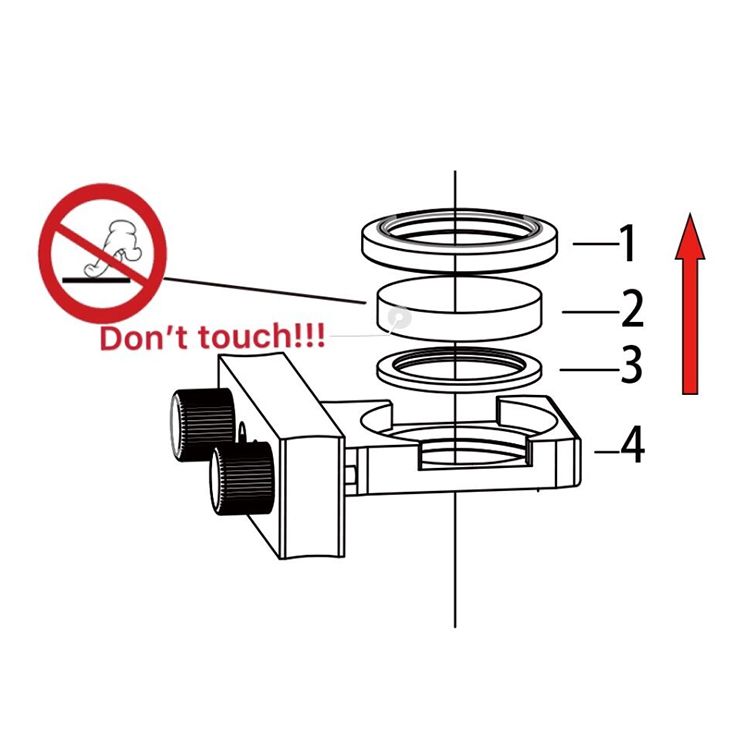

1. Wear anti-static dust-proof gloves when cleaning to prevent dust from contaminating the lens.

2. A dust-free workbench should be selected for cleaning.

3. The cleaning tool used should be a page lens cleaning tool.

4. Avoid hard objects touching the lens to avoid scratches.

5. Use the cleaning solution from the special page.

6. The cleaning action should be gentle, and wipe slowly from the center to the outside.

7. After cleaning, it should be loaded into the laser head immediately to avoid secondary pollution.

8. The lens should be cleaned regularly.

Parameters of laser cutter lens

Product name | Laser protection lens |

Material | Imported quartz |

Wavelength | 1064nm |

Diameter range | 18-150mm |

Diameter Tolerance | ±0.1mm |

Thickness range | 1-10mm |

Thickness Tolerance | ±0.1mm |

Transmittance | 99.99% |

Clear aperture | >80% |

Surface finish | 20/40 |

Parallelism | <0.01mm |