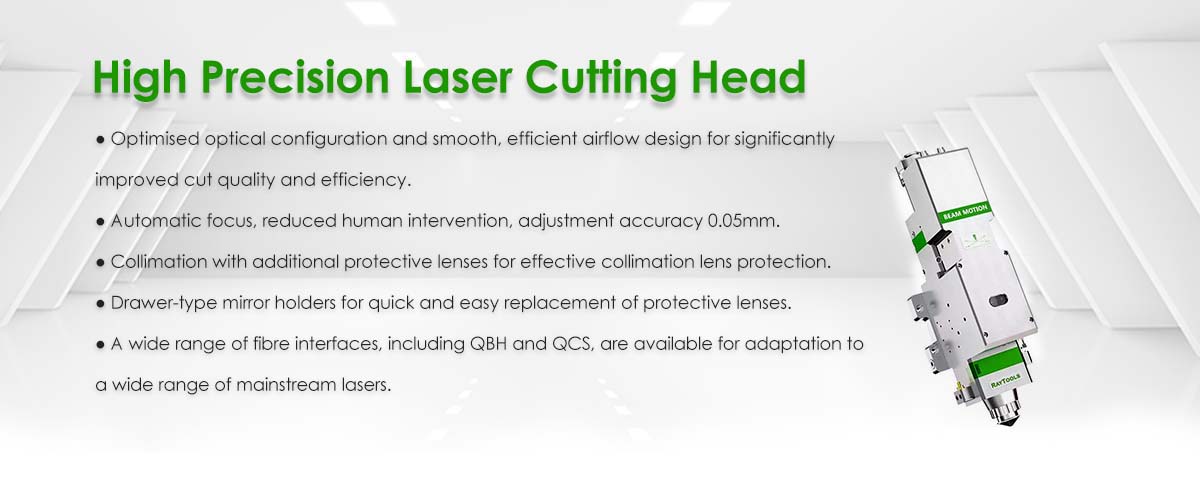

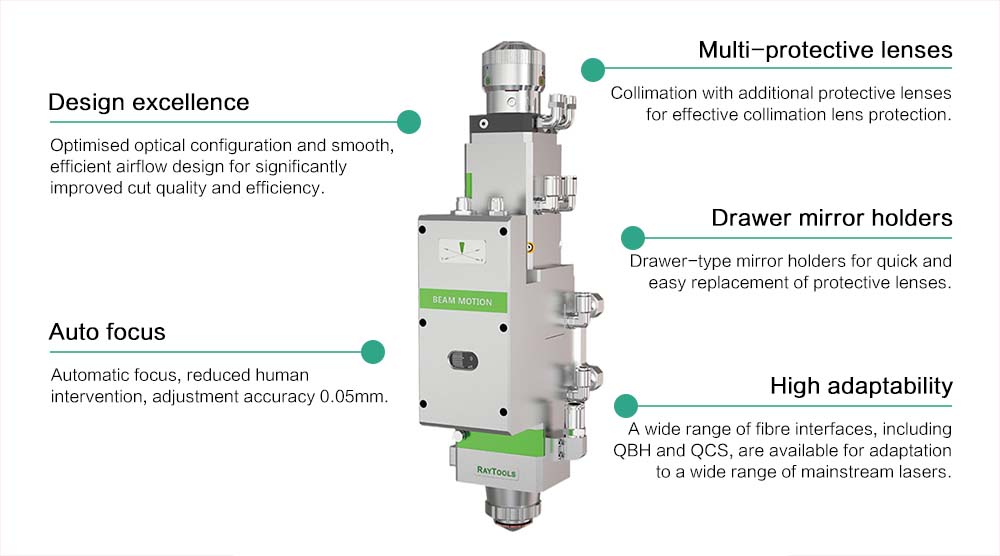

Features of high power laser cutting head

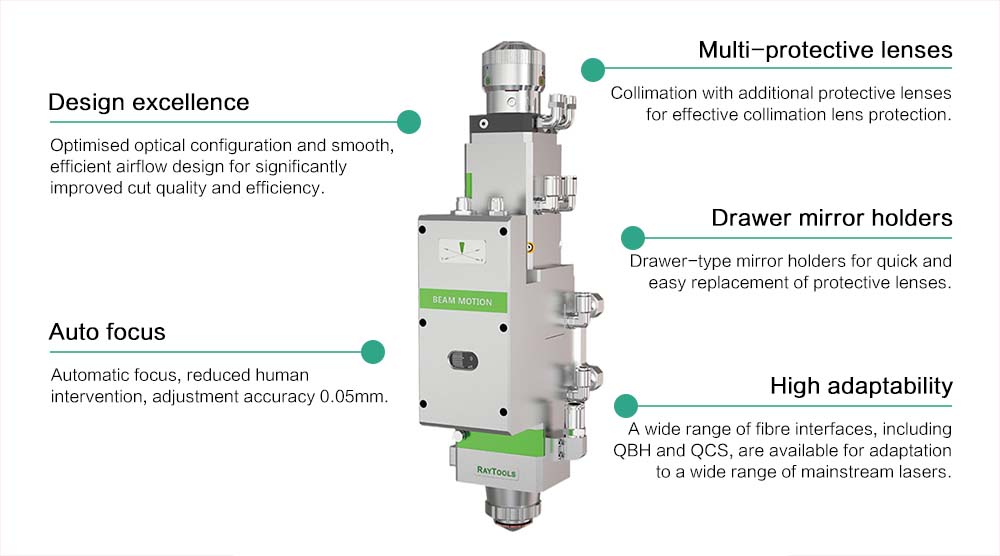

1. Optimized optical configuration and smooth and efficient airflow design.

2. Auto-focusing range +10~-12mm, adjustment accuracy 0.05mm.

3. All lines and air tubes are routed from inside to avoid unnecessary collision and damage.

4. Focusing lens drive maximum acceleration 10m/s², maximum speed 10m/min.

5. Adopt drawer type mirror holder, which makes protecting the lens more quickly and easily.

6. Adopt compound lens for collimation and focusing to get the best optical quality and cutting effect.

7. With QBH, QD, QCS, PAPI, LLK-D and other fiber interfaces can be adapted with various fiber lasers.

Advantages of high power laser cutting head

● Highly dust-proof: Dust-proof grade IP65, fully enclosed package optical path, the possibility of lens pollution is almost zero.

● Moving picture zero focus: The scale can be adjusted flexibly to make the zero focus position uniform, and no longer worry about adjusting process parameters.

● Efficient water cooling: The focusing mirror, collimating mirror and nozzle all have built-in cooling functions, which can strongly solve the problem of cutting heat.

● Optimized structure design: integrated body design, improved QBH optical fiber interface is no longer stuck due to water leakage and rust.

Components of high power laser cutting head

1. Nozzle

The part closest to the workpiece being cut. During the cutting process, the nozzle will form an air field on the cutting surface to blow away the slag generated during the cutting process and prevent the laser head from being polluted by foreign matter.

2. Focusing mirror

Concentrate the laser beam into a high-density light spot or light speed. The smaller the light spot, the higher the density, and the smaller the cutting gap formed on the workpiece surface, so as to achieve high-precision and high-speed cutting effect.

3. Tracking sensor

It can sense the cutting action of the equipment, the distance between the cutting head and the surface of the workpiece, the distance between the cutting head and the edge of the workpiece, etc.

4. Mirror

Change the beam direction from the laser. During the use of the reflector, in order to prevent the reflector from being damaged by the overheating of the light, it usually needs to be cooled with water.

Parameters of high power laser cutting head

Laser head |

Rated power | Up to 4KW |

Focal length | 100mm、125mm、150mm、200mm |

Clear aperture | 25mm |

Nozzle diameter | 0.5-3mm |

Nozzle Specifications | Single layer, composite, porous, shower type, customized |

Cutting pressure | ≤20Bar |

Focus range | -5mm-+8mm |

Weight | 1.5KG |

Collimator |

Collimation focal length | 60mm、75mm、100mm |

Clear aperture | 25mm |

Fiber optic interface | QBH、QD、LLK-B、PIPA-Q |

Height sensor |

Sensing distance range (recommended 1mm) | 0.2mm-8mm |

Calibration | Automatic calibration |

Reaction time | <1ms |

Temperature stability | 0°~45°,±5° |

Power requirements | 24V |

Output (linear curve or optimized curve) | 0~10V analog |