Features of laser cutting nozzle

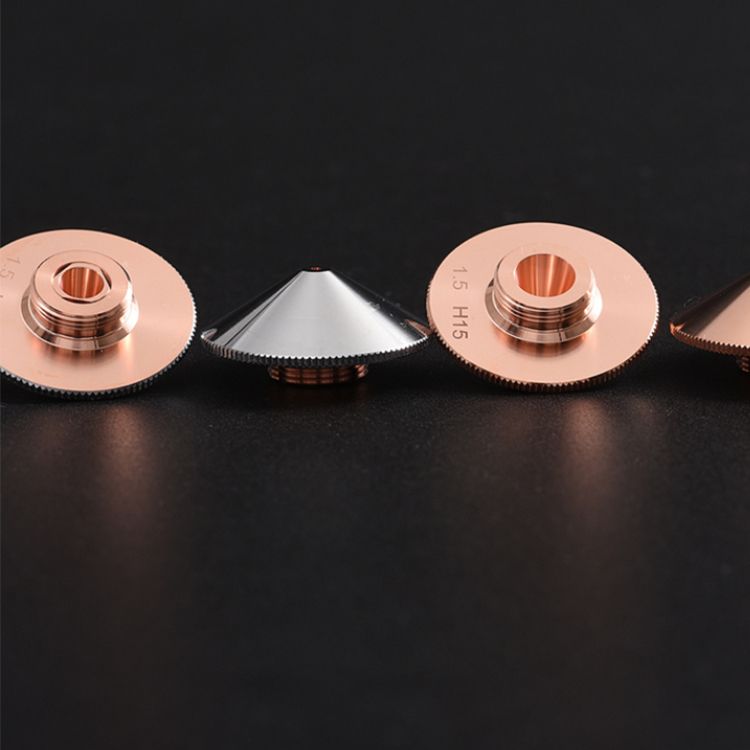

1. Imported copper: different from the general purple copper brass, using imported copper, high induction, high hardness and slag resistance, solid and durable.

2. Complete specifications: a complete range of types and models.

3. Precision production: strict anti-oxidation process, copper color bright and durable, effectively extend the use of time, improve cutting efficiency and quality.

4. High temperature resistance and less slag: high precision processing, fast cutting speed and long service life.

Role of laser cutting nozzle

● to prevent melt stains and other debris from bouncing upward, through the nozzle and contaminating the focusing mirror.

● control the gas diffusion area and size, so as to control the cutting quality.

Types of laser cutting nozzle

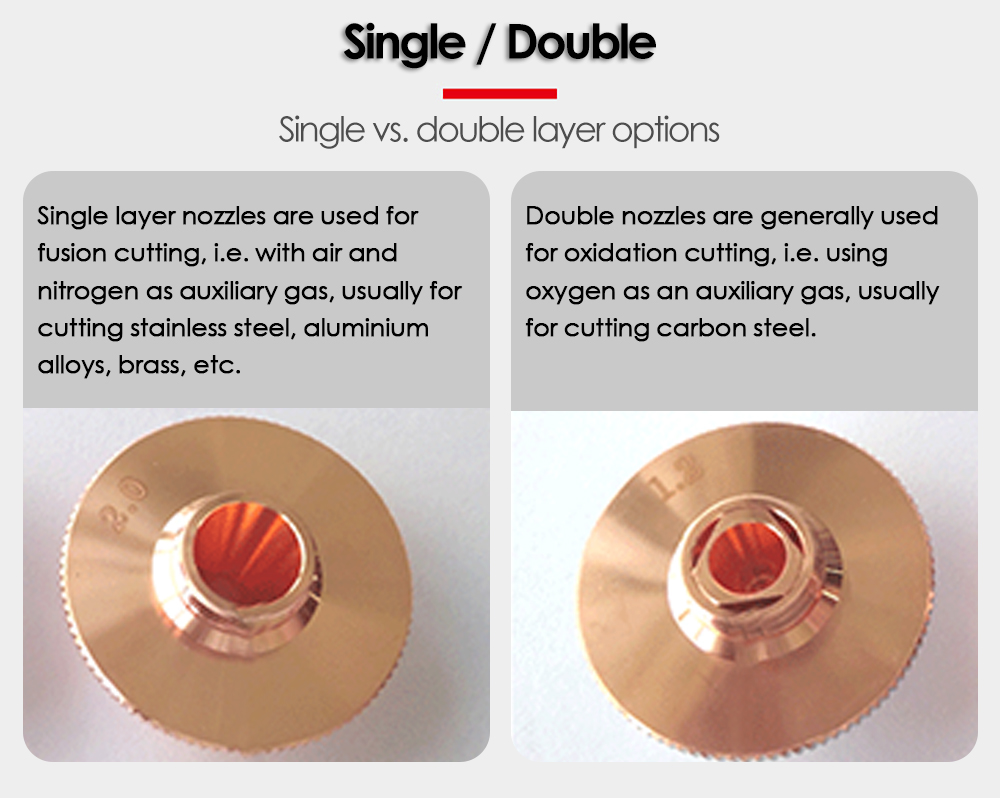

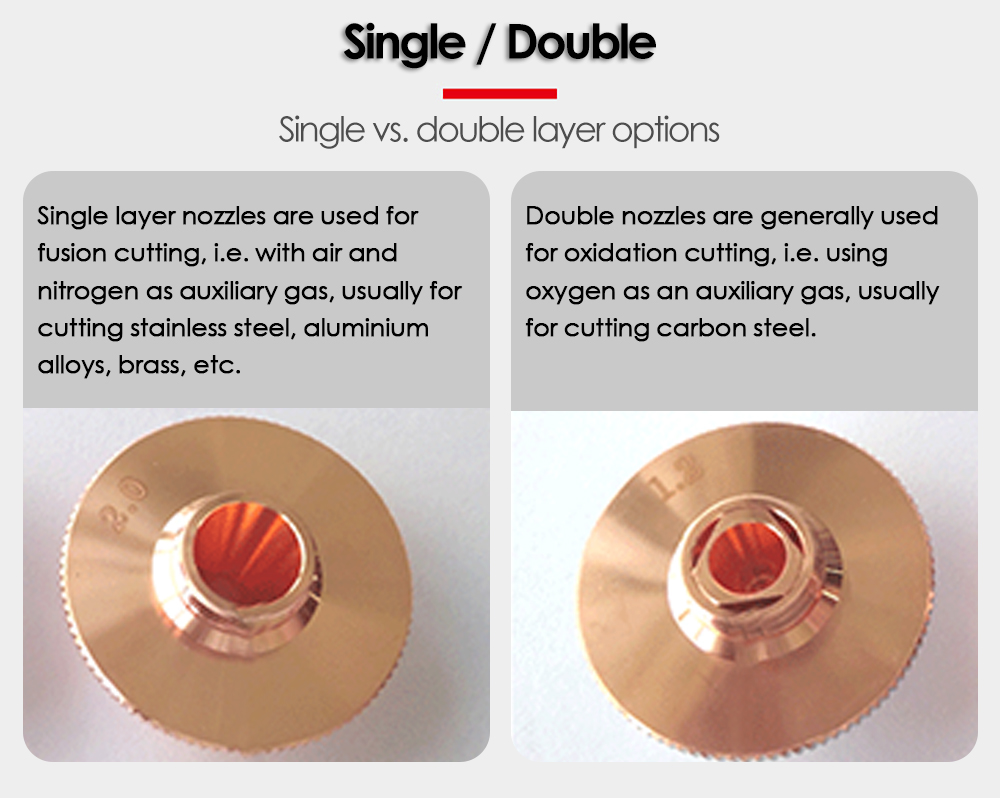

Nozzle is divided into single-layer and double-layer nozzle.

● Single-layer nozzle relative gas flow rate is slow, commonly used in cutting stainless steel, aluminum, copper and other metals, mostly using nitrogen as an auxiliary gas.

● Double nozzle gas flow rate is fast, suitable for high-speed cutting, commonly used for cutting carbon steel, generally with oxygen as an auxiliary gas.

Laser cutting nozzle selection

1. When cutting thin plate (below 3mm). Choose Φ1mm aperture nozzle will be thin, and choose Φ1.5mm aperture nozzle will be thicker, and the corner will be easier to have tolerance stains.

2. When cutting thick boards (3mm or more). The nozzle with Φ1mm aperture is less stable when used. Because the cutting power is higher at this time, the relative heat dissipation time is longer and the relative cutting time also grows, so the gas diffusion area with Φ1mm aperture nozzle is small, so it is less stable, but basically it can still be used. And choose Φ1.5mm aperture nozzle gas diffusion area is large, the gas flow rate is slower, so the cutting is more stable

3. When cutting plates of 10mm or more. At present, the general choice of diameter 2mm or 2mm or more aperture nozzle.

As the larger the aperture of the nozzle, the smaller the protective effect on the focusing mirror. So a reasonable choice of laser cutting machine nozzle aperture size, in order to be more effective in production.

Parameters of laser cutting nozzle

Shape | Outer diameter | High | Single double layer | Thread | Caliber |

Straw hat style | 28 | 15 | single layer | M11 | 0.8-10.0 |

32 | 15 | single layer | M14 | 0.8-10.0 |

Regular style | 28 | 15 | single layer | M11 | 0.8-10.0 |

32 | 15 | double layer | M14 | 0.8-10.0 |

High speed style | 28 | 15 | single layer | M14 | 0.8-10.0 |

32 | 15 | double layer | M14 | 0.8-10.0 |

Jiaqiang style | 28 | 15 | single layer | M14 | 0.8-10.0 |

32 | 15 | double layer | M14 | 0.8-10.0 |

Bullet style | 10.5 | 22 | single layer | M14 | 0.8-4.0 |

10.5 | 22 | double layer | M14 | 0.8-4.0 |