The components of the laser cutting machine cutting head are: nozzle, focusing lens and focus tracking system.

1. Nozzle

The form of the nozzle and the size of the nozzle have a great influence on the cutting quality.

2. Focusing lens

To use the energy of the laser beam for cutting, the original beam emitted by the laser must be focused through the lens to form a spot with high energy density. According to Gaussian optics theory, the power density is highest at the focal point. The longer the focal length of the lens, the larger the focus spot and the lower the power density, but the depth of focus is larger (the depth of focus refers to the distance between the two spots with a diameter change of 5% on both sides of the focus, which is also called the effective cutting range in cutting), and the operating tolerance big.

3. Tracking system

The laser cutting machine focus tracking system is generally composed of a focus cutting head and a tracking sensor system. The cutting head is composed of light guide focusing, water cooling, air blowing and mechanical adjustment; the sensor is composed of sensing element and amplification control part.

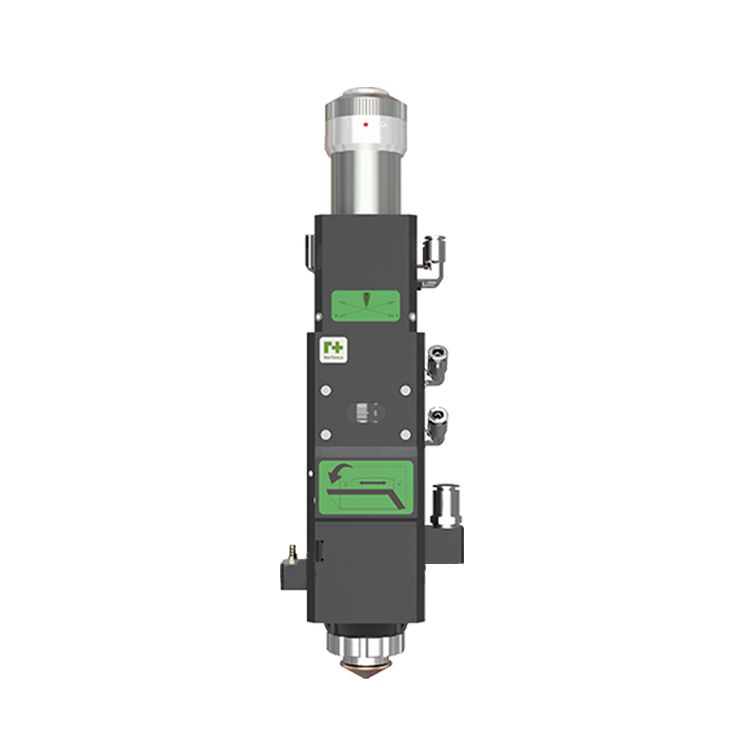

Features of fiber laser cutting head

1. Excellent design

Optimized optical configuration and smooth airflow design significantly improve cutting quality and efficiency.

2. Auto focus

Automatic focusing, reducing human intervention, automatic focusing range -12~+10mm, focusing accuracy 0.05mm.

3. Multiple protective lenses

Collimation increases the protective lens to effectively protect the collimation lens.

4. Drawer mirror holder

Protective lens replacement is quick and easy.

5. High adaptability

Equipped with multiple fiber interfaces such as QBH and QD, it can be adapted to various mainstream lasers.

Effect of fiber laser cutting head

Laser cut heads are generally composed of nozzle, focusing mirror, auxiliary system, and focusing detection system.

Can make the light spots higher in industrial processing and improve processing efficiency. And according to the actual processing scene, adjust the shape of the laser spots and depth of processing when it is out of light. Add some specific monitoring modules and displacement systems, which can have a good packaging, which can effectively reduce splashing and protective lenses.

Parameters of fiber laser cutting head

Laser head |

Rated power | Up to 4KW |

Focal length | 100mm、125mm、150mm、200mm |

Clear aperture | 25mm |

Nozzle diameter | 0.5-3mm |

Nozzle Specifications | Single layer, composite, porous, shower type, customized |

Cutting pressure | ≤20Bar |

Focus range | -5mm-+8mm |

Weight | 1.5KG |

Collimator |

Collimation focal length | 60mm、75mm、100mm |

Clear aperture | 25mm |

Fiber optic interface | QBH、QD、LLK-B、PIPA-Q |

Height sensor |

Sensing distance range (recommended 1mm) | 0.2mm-8mm |

Calibration | Automatic calibration |

Reaction time | <1ms |

Temperature stability | 0°~45°,±5° |

Power requirements | 24V |

Output (linear curve or optimized curve) | 0~10V analog |