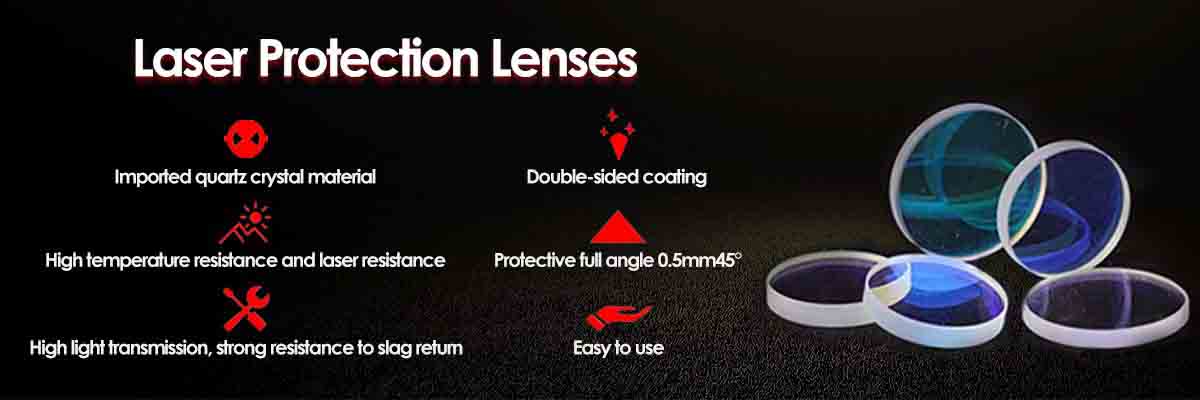

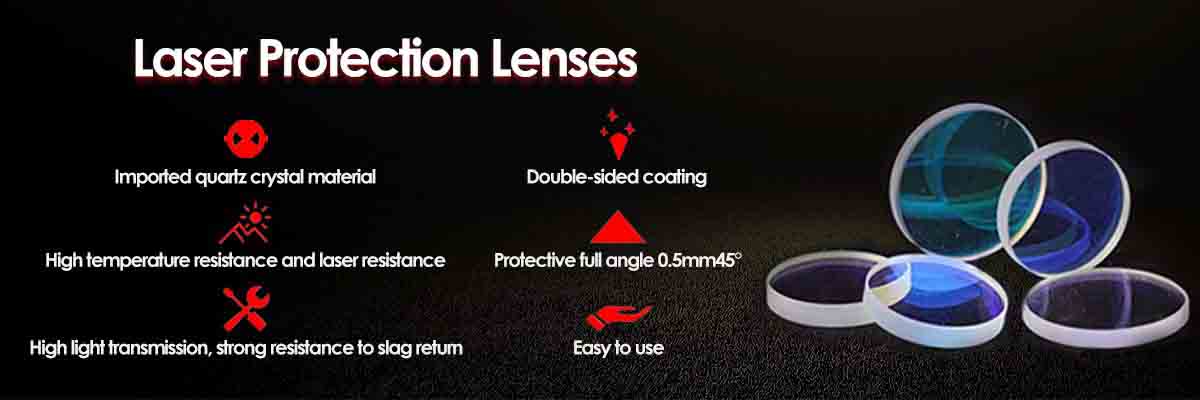

Features of fiber laser lens

● No chipping, not easy to crack

Imported quartz crystal material, uniform texture, high mechanical strength, high temperature resistance, high pressure, the lens is not easy to chip and crack.

● High temperature resistance, strong anti-laser performance

It is made of high-quality substrates with excellent optical performance and good thermal stability, and is finely processed through cutting, polishing, grinding and other high-precision processes. The lens is resistant to high temperature and has strong anti-laser performance.

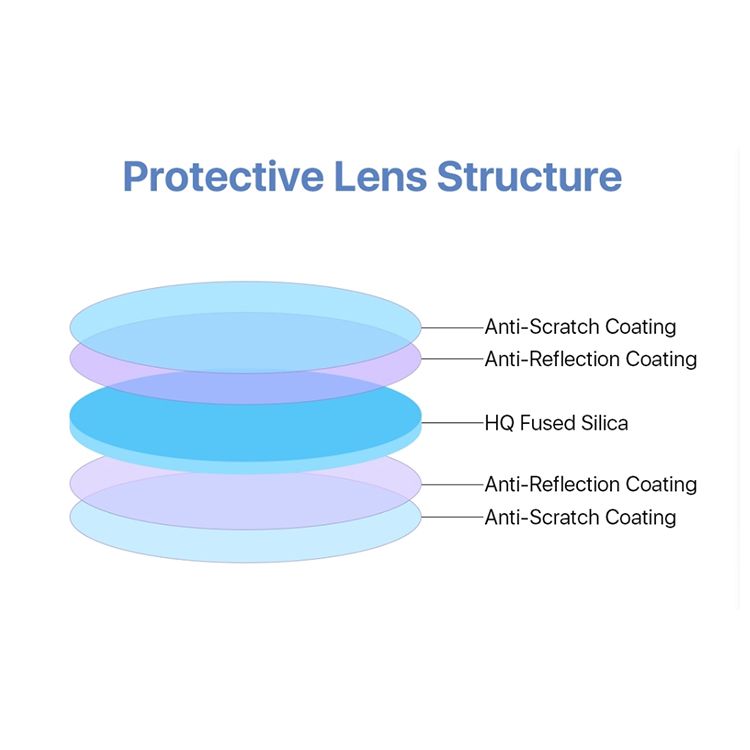

● High light transmittance, strong anti-slag resistance

Both sides of the lens are AR-coated with a high damage threshold to reduce losses due to reflections, and the coating protects them from splashes and other hazards for long life.

● Safe and easy to use without hurting hands

Humanized 45° protective full-angle design, easy to apply and not hurt your hands.

Hot specifications of fiber laser lens

P/N | Diameter | Thickness | Wavelength |

JGS1-D20-T2 | 20 | 2 | 1010-1090nm |

JGS1-D20-T3 | 20 | 3 | 1010-1090nm |

JGS1-D20-T5 | 20 | 5 | 1010-1090nm |

JGS1-D22.35-T4 | 22.35 | 4 | 1010-1090nm |

JGS1-D25-T2 | 25 | 2 | 1010-1090nm |

JGS1-D25-T3 | 25 | 3 | 1010-1090nm |

JGS1-D25.4-T4 | 25.4 | 4 | 1010-1090nm |

JGS1-D25.4-T5 | 25.4 | 5 | 1010-1090nm |

JGS1-D27-T4 | 27 | 4 | 1010-1090nm |

JGS1-D28-T4 | 28 | 4 | 1010-1090nm |

JGS1-D30-T1.5 | 30 | 1.5 | 1010-1090nm |

JGS1-D30-T5 | 30 | 5 | 1010-1090nm |

JGS1-D32-T4 | 32 | 4 | 1010-1090nm |

JGS1-D34-T3 | 34 | 3 | 1010-1090nm |

JGS1-D34-T5 | 34 | 5 | 1010-1090nm |

JGS1-D35-T1.5 | 35 | 1.5 | 1010-1090nm |

JGS1-D35-T4 | 35 | 4 | 1010-1090nm |

JGS1-D36-T5 | 36 | 5 | 1010-1090nm |

JGS1-D37-T7 | 37 | 7 | 1010-1090nm |

JGS1-D38-T2 | 38 | 2 | 1010-1090nm |

We can provide lenses for any wavelength according to customer requirements. For other wavelengths, diameters and thicknesses of lenses, we can also produce them on request.

Main function of fiber laser lens

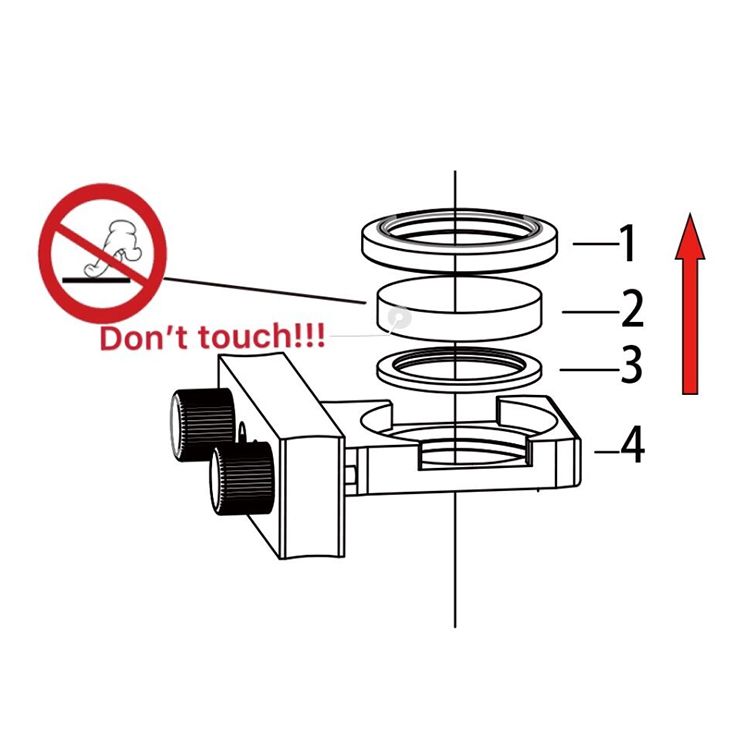

Protect the focusing lens, prevent splashes from splashing onto the lens and cause damage to the lens, and ensure the processing accuracy requirements by regularly replacing the protective lens.

Laser lens wipe steps

1. Wash your hands well and blow dry or leave to dry.

2. Put on the finger glove.

3. Gently remove the lens and inspect it.

4. Blow off the dust on the surface of the lens with an air ball or nitrogen gas.

5. Remove the residue with a cotton ball soaked with lens cleaning solution.

6. Gently wipe the lens with the appropriate amount of wiping solution on the wiping paper, do not wipe in a rotating manner.

7. Replace the wipe paper and repeat step (6), do not reuse the same wipe paper.

8. Use the air ball to blow the mirror surface clean again.

Parameters of fiber laser lens

Product name | Laser protection lens |

Material | Imported quartz |

Wavelength | 1064nm |

Diameter range | 18-150mm |

Diameter Tolerance | ±0.1mm |

Thickness range | 1-10mm |

Thickness Tolerance | ±0.1mm |

Transmittance | 99.99% |

Clear aperture | >80% |

Surface finish | 20/40 |

Parallelism | <0.01mm |