Details Product Parameters Samples Video

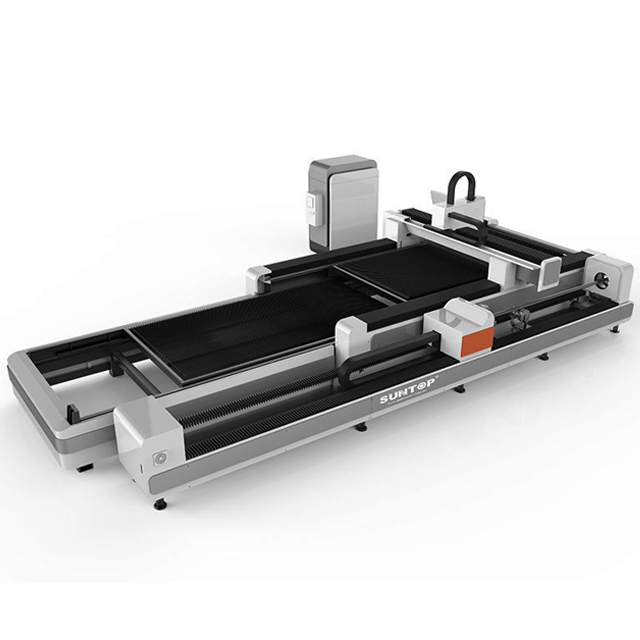

Features of metal fiber laser cutting machine

1. The interchangeable table structure enables loading and unloading of plates and cutting at the same time, the transmission mode is stable and reliable, and the exchange time is shortened.

2. The front and rear chucks and drill bits are driven by servo motors, cutting without vibration, high precision and good synchronization.

3. High-quality guide rail and rack and pinion transmission, high rigidity, smooth operation, low noise, smooth operation, and reduce shock and vibration.

4. Electric self-centering chuck, without manual adjustment, any material with a diameter of 20-150mm does not need to be centered.

5. Automatic tracking system for calibration and automatic tracking of wavy metal plates.

Details of metal fiber laser cutting machine

1. Clamping design

The front and rear are clamped by pneumatic chucks, the center is automatically adjusted, and the operation is simple.

It can process ultra-large diameter pipes, and the chuck rotates at a high speed, which can improve processing efficiency.

2. Cast aluminum beam

The overall cast aluminum beam is refined through artificial aging and solution treatment, which endows the beam with excellent integrity, rigidity and good toughness.

Light weight, corrosion resistance, oxidation resistance, low density, fast cutting of various graphics while satisfying the precision.

3. Suntop patented design universal shaft drive exchange platform

Good synchronization performance, high exchange torque, strong overload resistance, long-term reliable operation without failure. Equipped with high power mid-mounted 3KW motor with brake system and hardened gear reducer, large torque output, symmetrical 80mm diameter universal shaft torque transmission, double 16mm chains to drag the table.

4. Suntop laser cutting head lift (Z-axis)

Adopt closed module, fully sealed and protected, effectively prevent cutting dust and smoke from entering the module, avoid and reduce malfunction. Internal integration of ball screw and linear guide, etc., with high integration, small size and high operating accuracy.

5. Laser cutting head

The focal length scale can be adjusted flexibly, no need to manually adjust the focus, and it is easy to operate. Control the vertical height, auto-focus, quickly complete the high-speed perforation of thick plates, and automatically cut materials of different thicknesses.

Advantages of metal fiber laser cutting machine

1. It adopts the exchange double platform, which can realize the double cutting function of plate and pipe. One piece of equipment completes multiple processes, which not only reduces the area occupied by the equipment, but also reduces the cost investment of the equipment.

2. Using a unified fixture, the entire machining process is completed by programming software. The cutting precision is high, the cutting surface is smooth and beautiful, the kerf is small, the finished workpiece has no deformation, and can directly enter the next process.

3. Support bevel cutting, double chuck clamping, suitable for various special-shaped pipe fittings.

4. The double sprocket structure has a longer service life, and the flexible track has strong adaptability to the deformation of rough steel pipes.

5. Fully intelligent numerical control system, human-computer interaction interface, easy to operate.

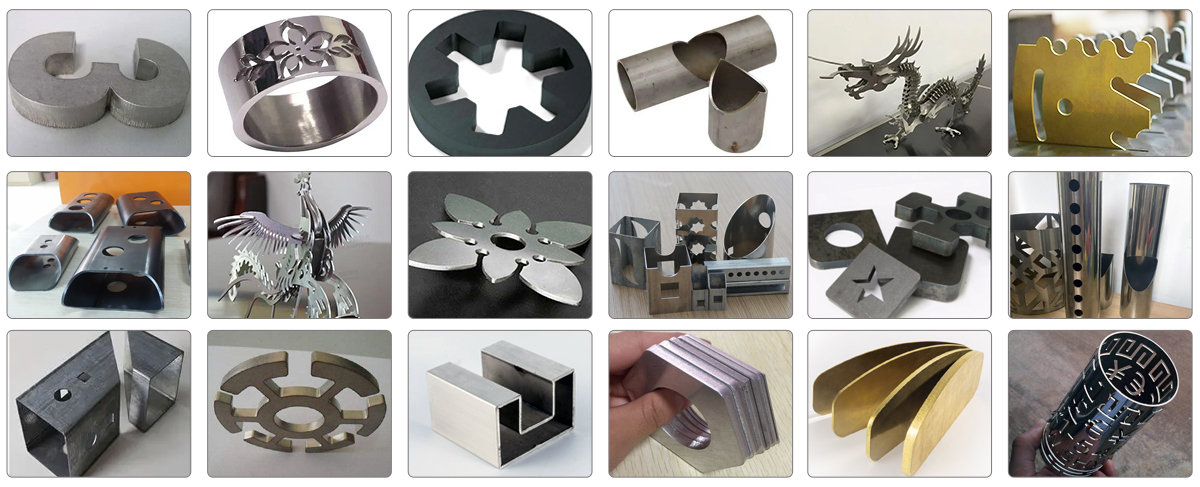

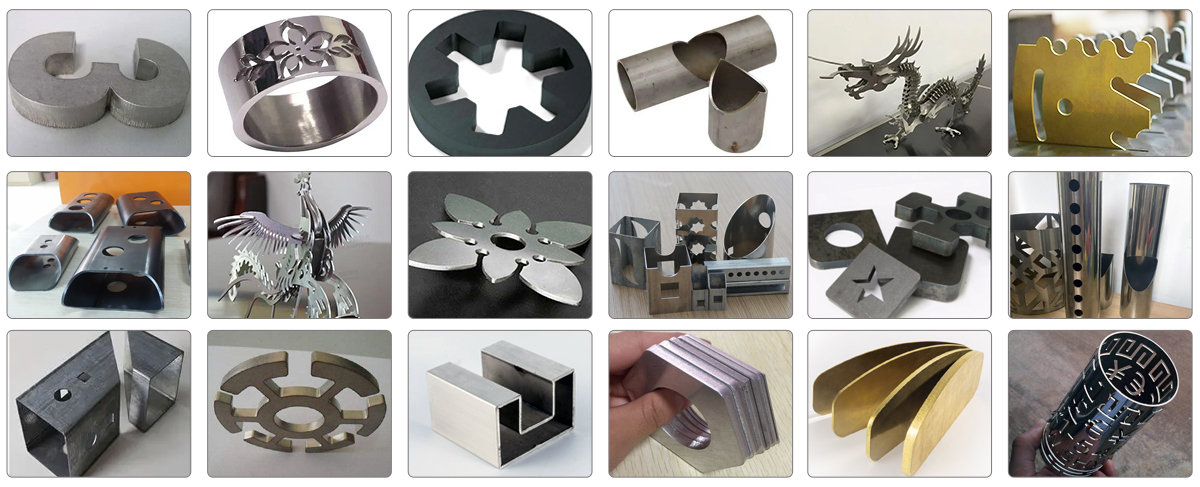

Metal fiber laser cutting machine application

Application materials

Mainly cutting a variety of metal plates and tubes, suitable for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Application industry

Widely used in national key industrial fields such as aviation, metallurgy, shipbuilding, and equipment, as well as manufacturing industries such as automobiles, machinery, sheet metal, packaging, agricultural equipment, kitchen utensils, medical equipment, sports equipment, environmental protection equipment, elevator equipment, and advertising signs.

Parameters of metal fiber laser cutting machine

Model | ST-FC3015CR/ST-FC4020CR/ST-FC6015CR/ST-FC6020CR |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 6000*1500mm, 6000*2000mm) |

Laser wavelength | 1064nm |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Maximum speed | 120m/min |

Repeat positioning accuracy | ±0.02mm |

Tube cutting standard range | 20mm≤Round tube≤220mm,

20mm≤Square tube≤150mm

Other size can be customized |

Tube cutting standard length | 3000mm/6000mm (other length can be customized) |

Power consumption | <10KW (based on laser power 1000W) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 9000KG |

Machine dimension | 5050*2480*1830mm (L*W*H) |