Details Product parameters Samples Video

Features of full enclosed fiber laser cutting machine

1. Fully enclosed design, with air-conditioned room and dust isolation/automatic tracking smoke exhaust system, energy saving and perfect smoke exhaust effect. It can work continuously for 24 hours, effectively prolonging the service life of optical components and electrical components of the machine.

2. The mechanical transmission part has been tested and calibrated by the laser interferometer many times to ensure that our machine can maintain good and stable accuracy even after several years of use.

3. It adopts a high-power hollow structure machine tool, which effectively reduces the heating area during the laser cutting process. Our machine tools are welded with thick steel plates, and the weight of only one machine tool reaches 4 tons. The stability of the machine is greatly improved, and it will not be deformed after at least 20 years of use.

4. Monitoring system, cameras are installed on the front and rear workbenches of the machine, which can effectively monitor the working status of the workbench.

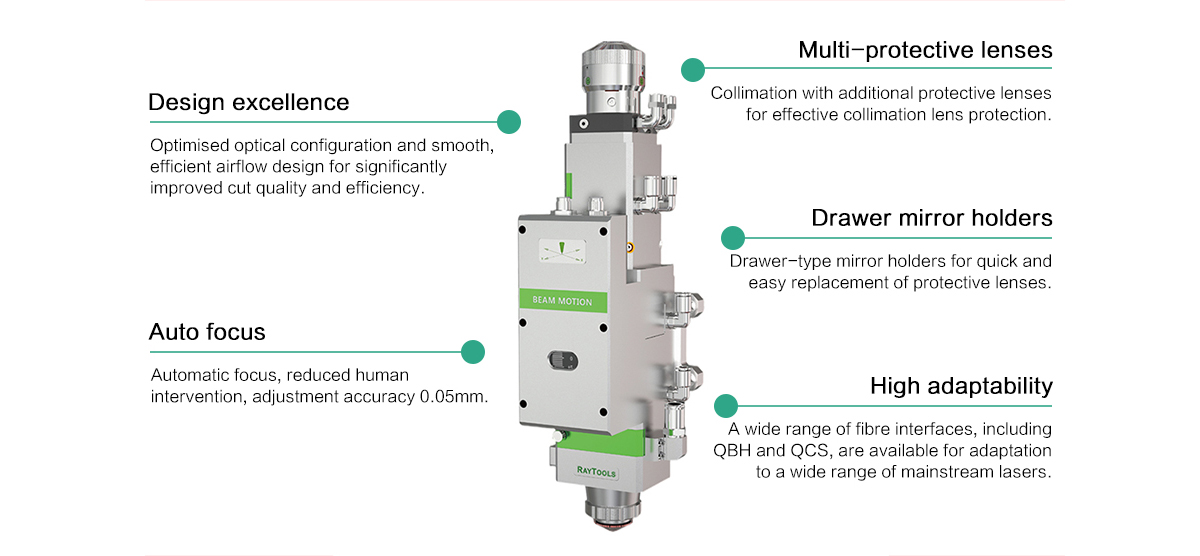

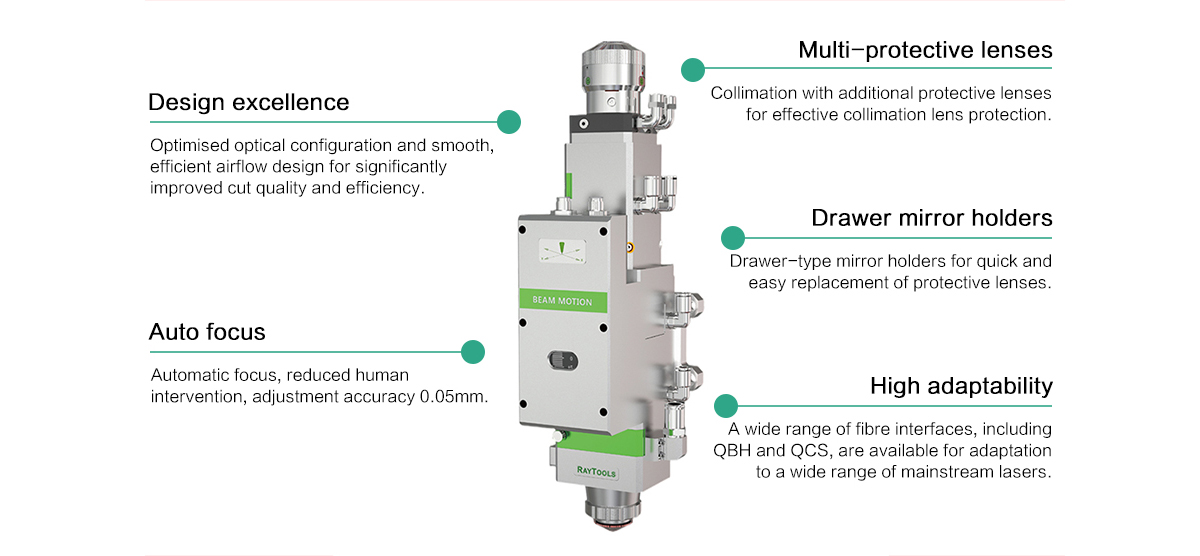

5. Using professional Raytools fiber laser cutting head, imported optical lens, smaller focusing spot, more precise cutting line, ensuring higher efficiency and better processing quality. Equipped with non-contact automatic follow function to ensure the best focusing and cutting effect.

6. Optical fiber transmission, flexible processing, to ensure the cutting quality at any point.

7. Professional laser CNC control system (Cypcut cutting software), computer operation, easier to operate.

8. Compatible with a variety of software, can design a variety of graphics or text instant cutting, simple, flexible and convenient operation

9. With intelligent discharge function, the material utilization rate is higher.

10. The machine can be equipped with automatic nesting function.

Details of full enclosed fiber laser cutting machine

1. Fiber laser source

Adopt well-known brands of Raycus, MAX, IPG and other fiber lasers. Better and more stable beam quality, stronger anti-high reflection ability, strong reliability and long life.

2. Raytools automatically adjusts the laser head

The focus scale can be adjusted flexibly, without manual focus adjustment, and the operation is convenient. Control the vertical height, auto-focus, quickly complete the high-speed perforation of thick plates and automatically cut materials of different thicknesses.

3. Machine tool

The bed adopts integral welding structure, which is rough machined after annealing to eliminate internal stress, and finished after secondary vibration aging treatment, which greatly improves the stability of the machine tool. The upper side of the main beam of the bed is paved with composite armor, which can effectively improve the impact of the high temperature generated during high-power laser cutting on the overall structure of the machine frame; there is a smoke outlet under the bed, and the smoke is automatically smoked through the smoke exhaust pipe, which can make the cutting process The smoke and dust generated can be easily discharged outdoors, which improves the working environment; the entire working area adopts a fully enclosed cover, and the safety protection is reasonable.

4. Crossbar

The gantry beam design is adopted, with light weight, good rigidity, good dynamic performance and stable operation. The fully enclosed dust-proof structure greatly improves the service life of the built-in rack and pinion and linear guide. Anti-corrosion, anti-oxidation, good toughness, and highly flexible.

5. Rack and pinion

Grinding gear technology is adopted to adapt to various use conditions, dustproof, and ensure long-term high-precision movement.

Advantages of full enclosed fiber laser cutting machine

(1) High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cutting surface without burrs.

(2) The laser cutting head will not touch the surface of the material and will not scratch the workpiece.

(3) The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

(4) Good processing flexibility, can process arbitrary graphics, and can also cut pipes and other special-shaped materials.

(5) High performance, using imported fiber laser, stable performance, service life can reach more than 100,000 hours.

(6) Low maintenance cost, photoelectric conversion efficiency of more than 30%, adopting air cooling, can greatly save power consumption during work, save operating costs, and achieve the highest production efficiency.

(7) Energy saving and environmental protection, equipped with professional dust removal equipment. Low noise, clean, safe and pollution-free.

Full enclosed fiber laser cutting machine application

Application materials

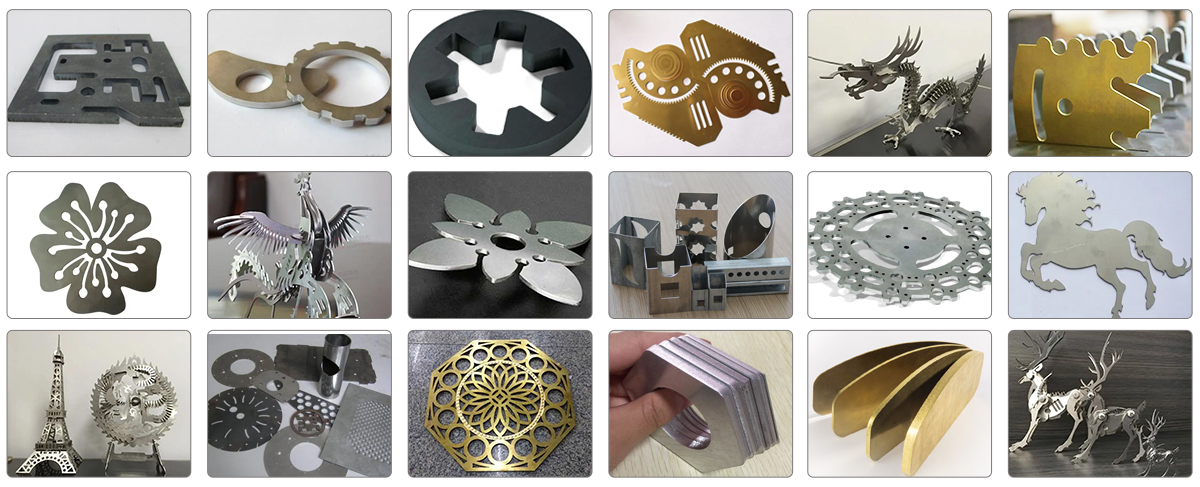

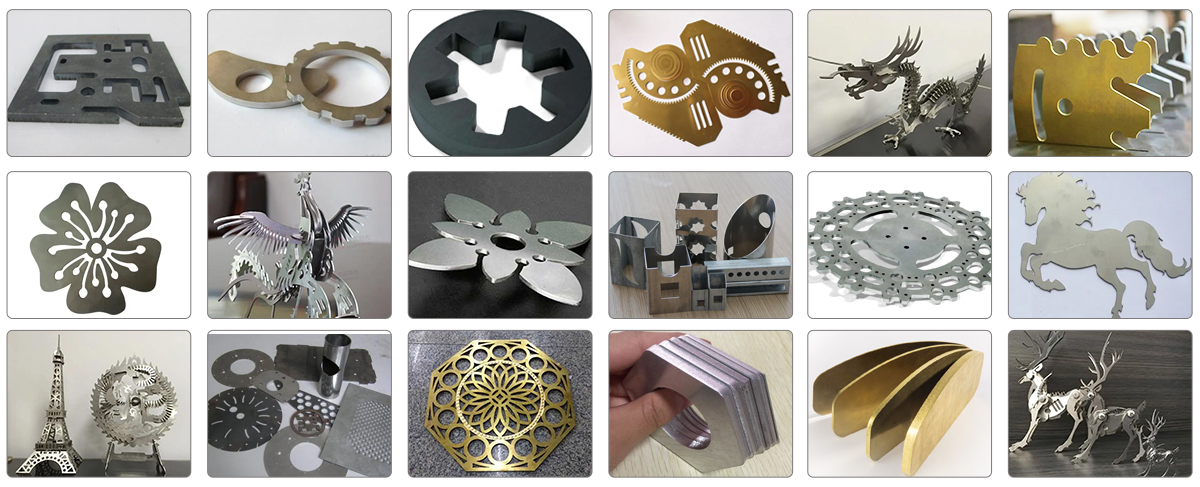

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating, zinc plate, metallic copper, brass • and other kinds of metals.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of full enclosed fiber laser cutting machine

Model | ST-FC3015G/ST-FC4020G/ST-FC1560G/ST-FC6020G/ST-FC6025G |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 1500*6000mm, 2000*6000mm, 2500*6000mm) |

Laser power | 1000W-20KW |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Laser wave length | 1064nm |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Maximum speed | 120m/min |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Equipment power | 8KW(not include laser generator and chiller) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc) |

Machine weight | 7500KG |

Machine dimension (L*W*H) | 8850*3210*2100mm |

Full enclosed fiber laser cutting machine samples