Detail Product parameters Sample Video

Product features of Single table fiber laser cutting machine

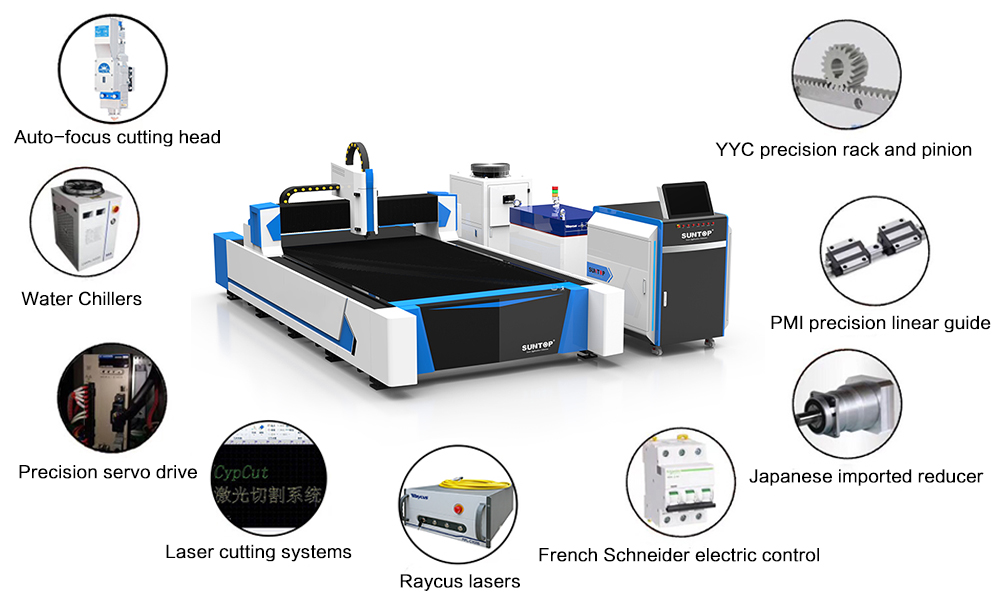

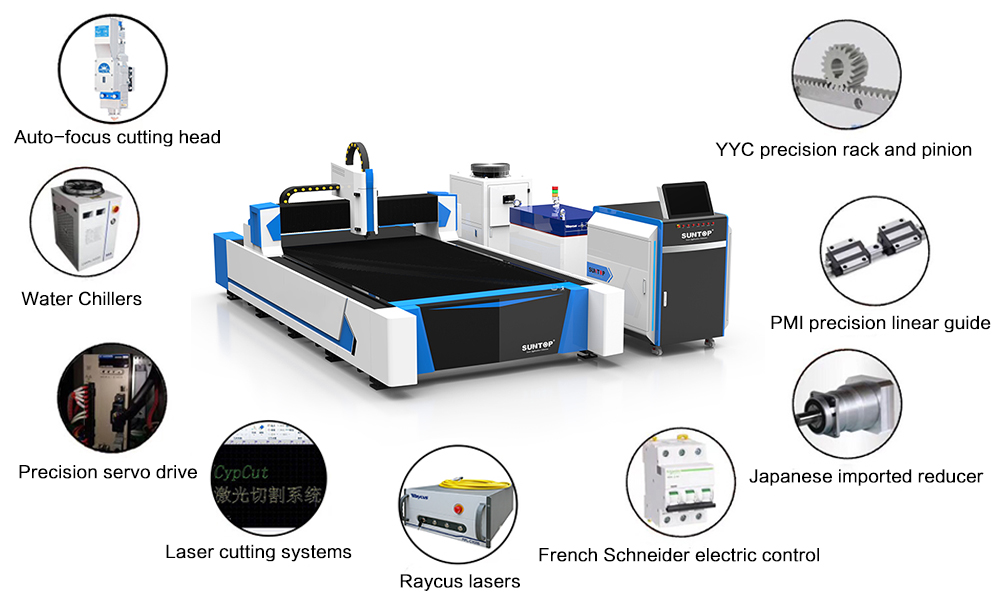

1. Imported high-precision double servo drive and guide drive, HIWIN embedded guide, stable drive, high precision.

2. The frame, crossbeam and table are welded as a whole, made according to the standard large machine, stress relieved and annealed, rough machined and then treated by vibration aging. It can completely eliminate the stress of welding and processing, maintain high strength and high precision, and keep normal use for 20 years without deformation.

3. The X and Y axes are equipped with Japanese servo motors with high precision, high speed, high torque, high inertia and stable performance, which ensure the high speed and acceleration of the whole machine.

4. The mechanical transmission part has been tested and calibrated by laser interferometer for many times to ensure that our machines can maintain good and stable accuracy even after several years of use, which is very important to the end users.

5. Adopted French Schneider AC servo system, with high power, stronger torque force, more stable working speed and faster speed.

6. Adopt professional Swiss Raytools laser cutting head, imported optical lens, smaller focusing spot, more accurate cutting line, ensure higher efficiency and better processing quality. Equipped with non-contact automatic following function to ensure the best focus and cutting effect.

7. Fiber laser emission, with brand-name laser generator, flexible processing, to achieve high precision cutting for every point.

8. Professional laser cutting CNC control system, connected with computer, easy to operate, French Schneider AC servo system, high power, stronger torque force, more stable working speed and faster.

9. Equipped with professional industrial HANLI or TEYU chiller, double temperature control mould, high cooling efficiency and high laser transmission rate. Japanese SMC intelligent gas set, double gas control, automatic adjustment of gas type and gas software.

10. Compatible with a variety of software, you can design graphics as you like, simple, flexible and easy to operate.

Cutting advantages of Single table fiber laser cutting machine

1. High cutting accuracy: laser cutting machine positioning accuracy 0.05mm, repeat positioning accuracy 0.03 mm.

2. Narrow cutting slit of laser cutting machine: the width of the kerf is generally 0.10-0.20mm.

3. smooth cutting surface of laser cutting machine: the cutting surface is burr-free and the surface roughness of the kerf is generally controlled to within Ra6.5.

4. Laser cutting machine speed: cutting speed can reach 60m/min.

5. Laser cutting machine cutting quality: no contact cutting, cutting edge by heat is very small, basically no thermal deformation of the workpiece, completely avoid the collapse of the edge formed when the material punching and shearing, cutting seam generally does not require secondary processing.

6. No damage to the workpiece: the laser cutting head does not come into contact with the surface of the material, ensuring no scratching of the workpiece.

7. not affected by the shape of the workpiece: laser processing flexibility, you can process any graphics, you can cut the pipe and other special profiles.

8. Save investment in molds: laser processing does not need molds, no mould consumption, no need to repair molds, save time to replace molds, thus saving processing costs and reducing production costs, especially suitable for processing of large products.

9. Save material: With computer programming, products of different shapes can be cut out to maximize the utilization of materials.

10. Safe and environmental friendly: laser processing has less waste, low noise, clean, safe and pollution-free, which greatly improves the working environment.

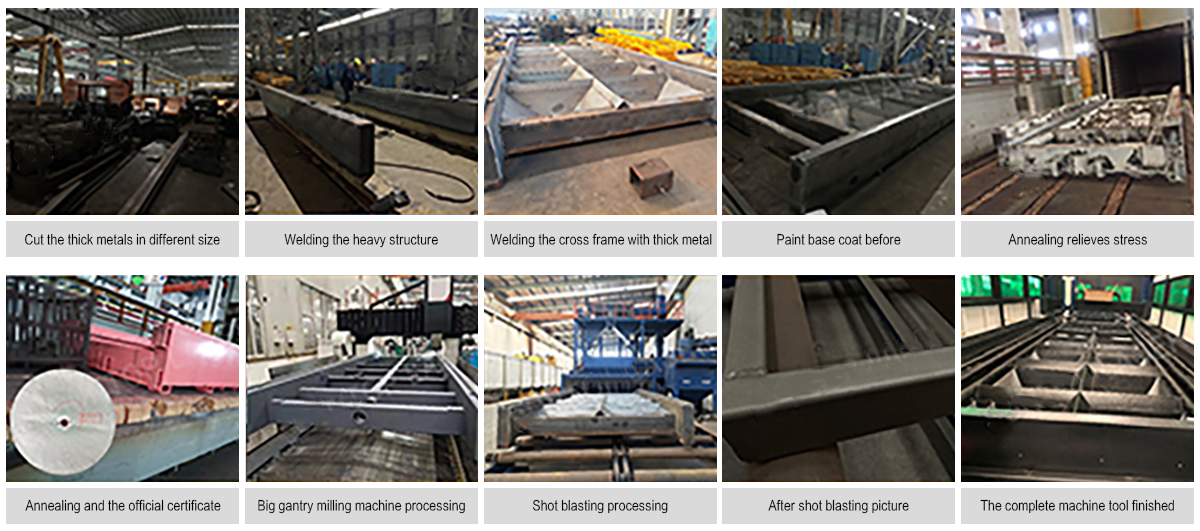

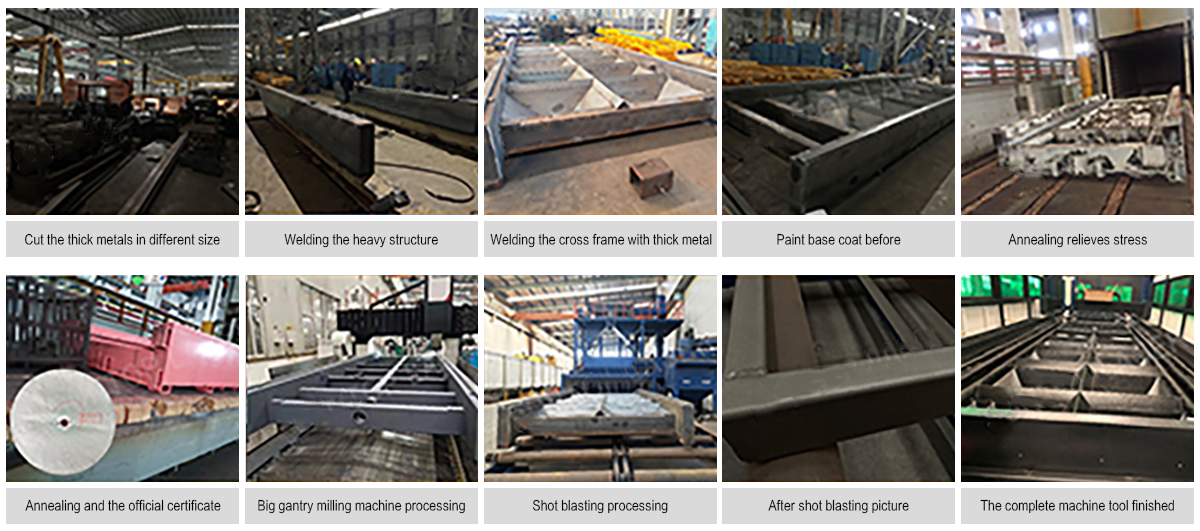

Advantages of fiber laser cutting machine machine tools

● We use a high-power machine tool with a hollow structure, which effectively reduces the heating area during the laser cutting process. The machine tool will not be deformed after long-term use, and it also ensures good cutting accuracy and greatly improves the stability of the machine. At least use 20 years will not deform.

● Our machine tools are welded with thick steel plates, and the weight of one machine tool alone reaches 4 tons.

● The cheap machine tools on the market are all welded with square tubes. The machine tools are light and thin. After 1-2 years of use, they will deform greatly, and there is almost no cutting accuracy.

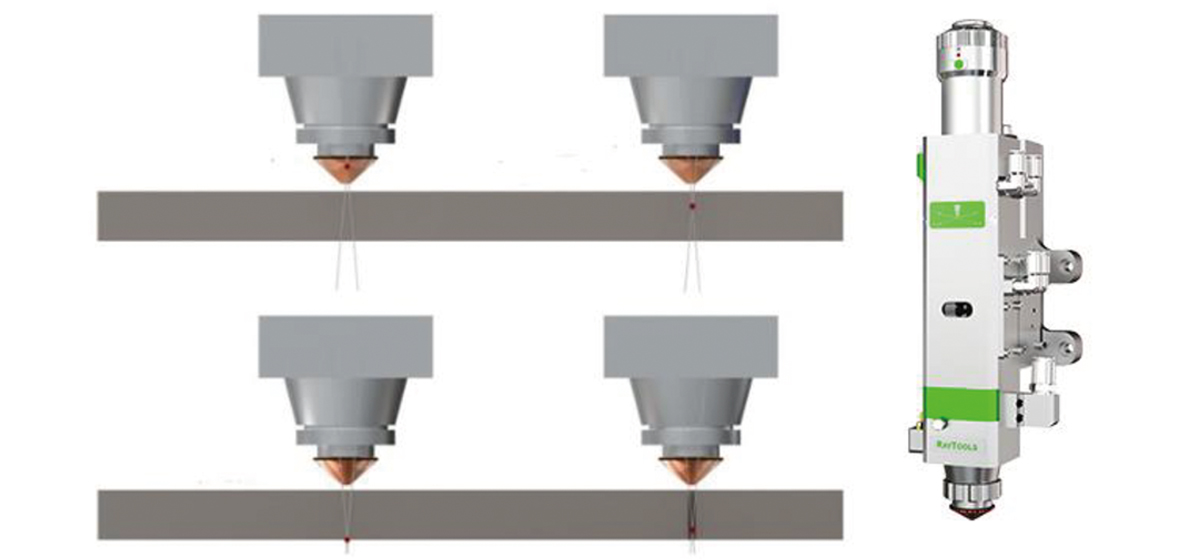

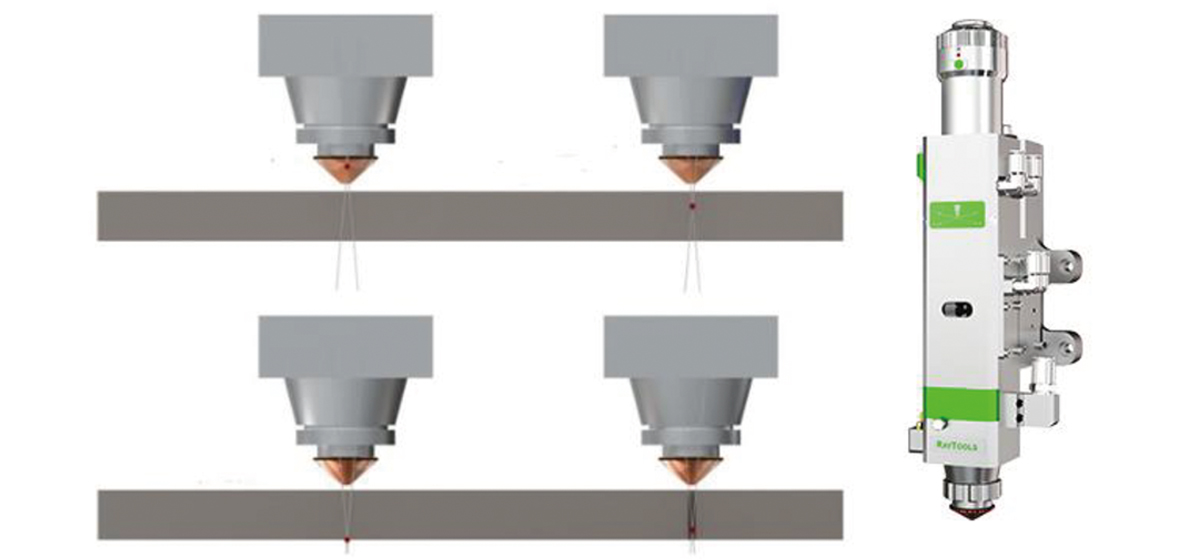

Core Part-Laser Head

◆ Without manual focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

◆ Bigger adjustment range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

◆ Long service life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

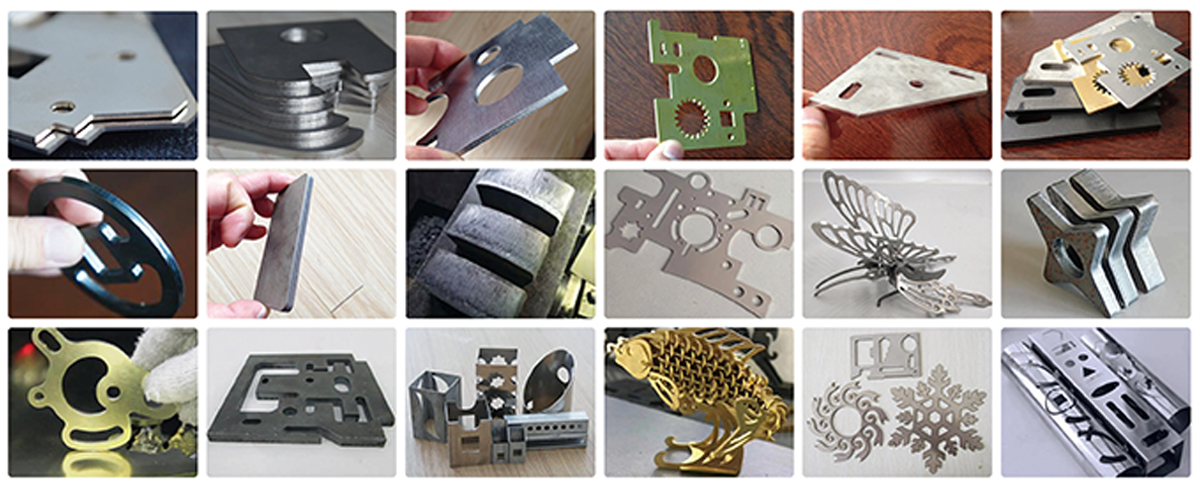

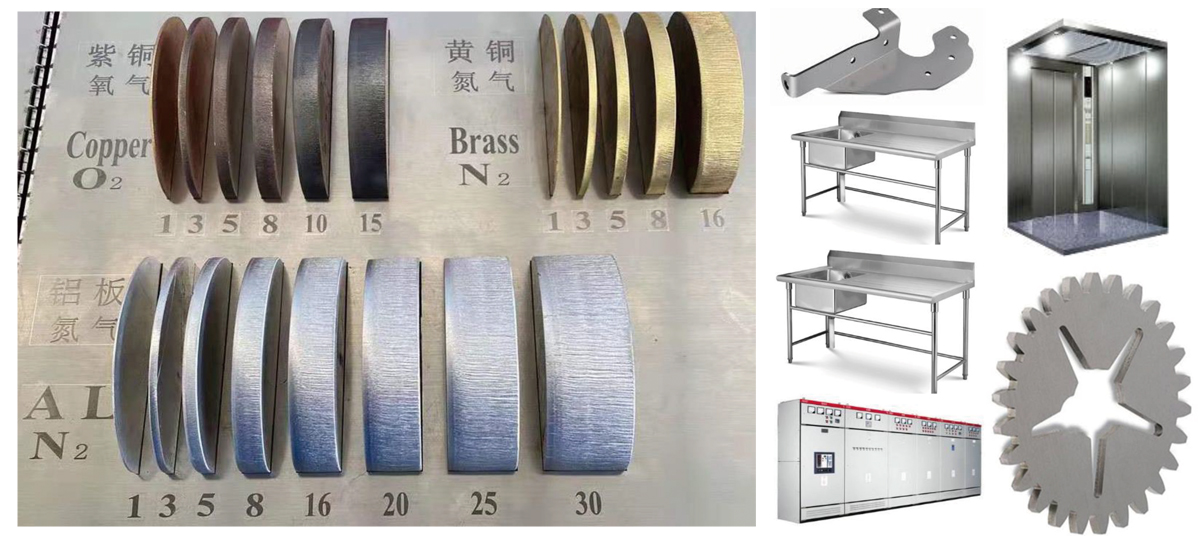

Fiber laser cutting machine application

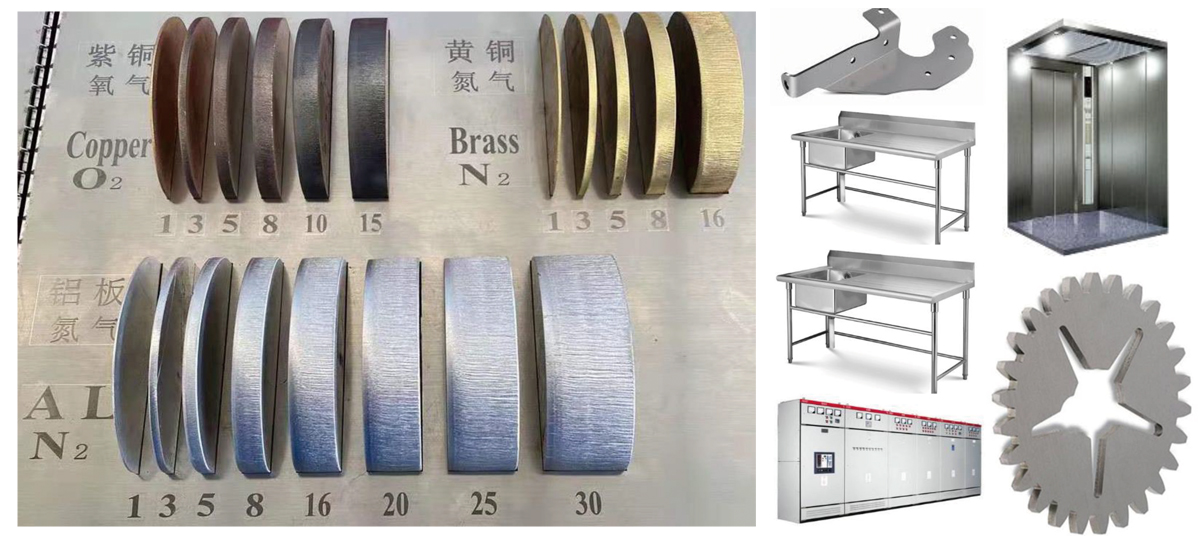

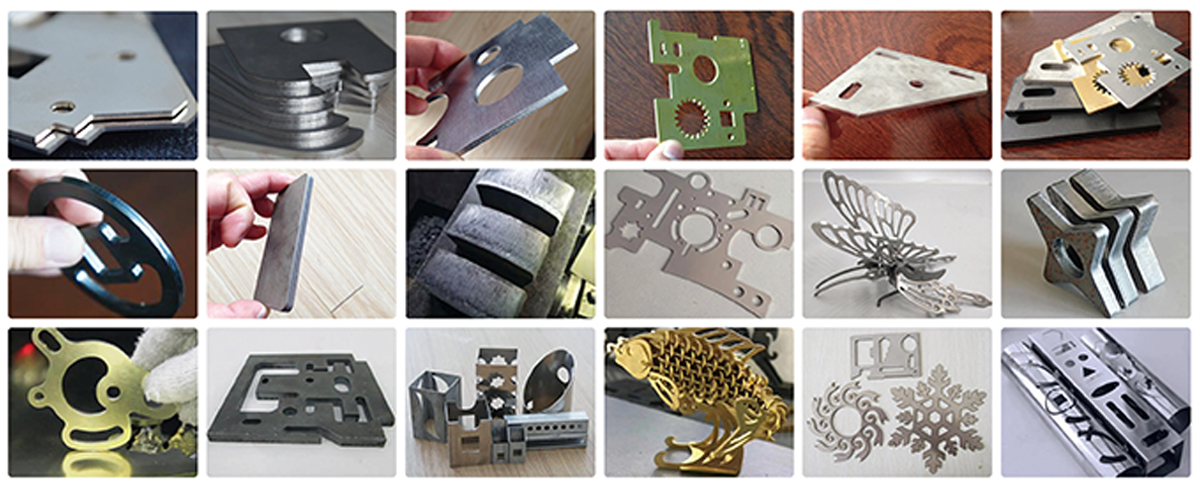

Application materials

mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, steel, various alloy plate, rare metal and other metal materials.

Application industry

Sheet metal processing, advertising signs production, high and voltage electrical cabinet production, mechanical parts kitchen utensils, automobiles, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tool and other metal processing industries.

Configuration of Single table fiber laser cutting machine

No. | Item | Description | Remark |

I Machine body |

1 | Square tube welding frame | Large gantry finish milling, double annealing | Han's Yueming |

2 | Linear guide rail | Imported precision grade | Germany-ROUST WORLD |

3 | Rack & pinion | Imported high speed and high precision | Germany-LEITESEN |

4 | Planetary reducer | Imported high precision | France brand-MOTOVARIO |

5 | Gantry | Finite element optimization, light weight and high rigidity | Han's Yueming |

II Laser source |

1 | Power | 1000W~2000W |

|

2 | Brand | IPG / Max |

|

III Optical system |

1 | Auto focus cutting head | Auto focus | Switzerland brand-Raytools

Optional: Germany Precitec |

IV Control and drive system |

1 | Motion Control System | Professional laser cutting software, operation is very simple | Han's Yueming |

2 | Motor | X-axis servo motor: 1KW, 2000rpm | France-Schneider |

Y-axis servo motor: 1.5KW, 2000rmp |

Z-axis servo motor: 400W, 3000rpm, with brake |

3 | Electrical control system | Electrical components are international brands such as

schneider | France brand |

4 | Industrial computer | I5-4200U/8G/120G/WIFI | China |

V Accessory |

1 | Cooling system | Double circulation system, over temperature alarm, flow

protection, water level protection | China/S&A |

2 | Exhaust blower | 380V/50Hz or 60Hz/3KW/2900rpm | Han's Yueming |

3 | Pneumatic components | Pressure regulating filter, solenoid valve, check valve, etc. | Taiwan/Japan |

4 | Precision electronically

controlled proportional valve | 0~1MPa | China |

5 | Optional: Voltage stabilizer | 30KVA or 60KVA | China |

6 | Optional: Air compressor | 30Kg air compressor & IV degree filter system & dryer | China |

7 | Optional: Dust collector |

| China |

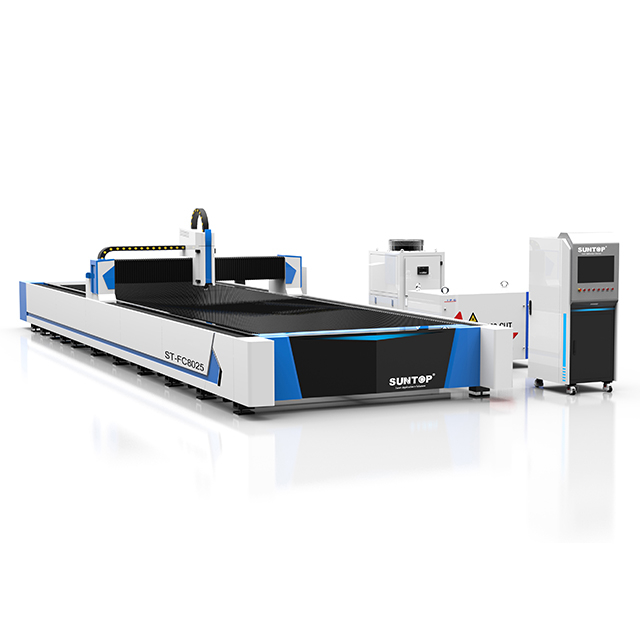

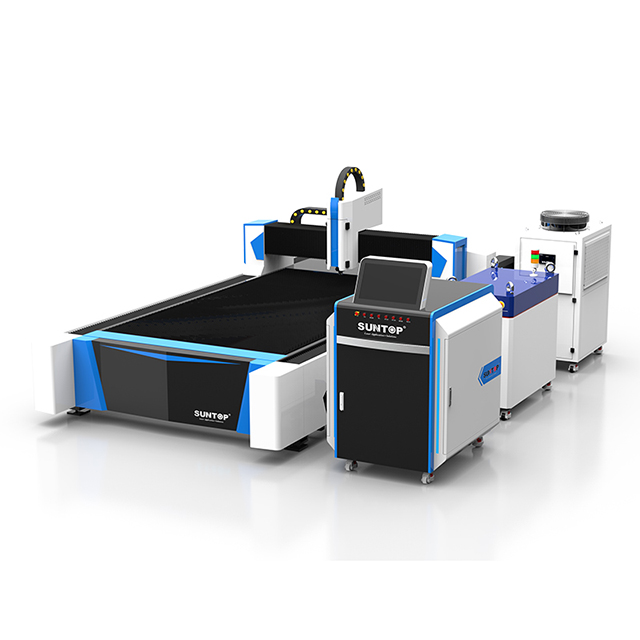

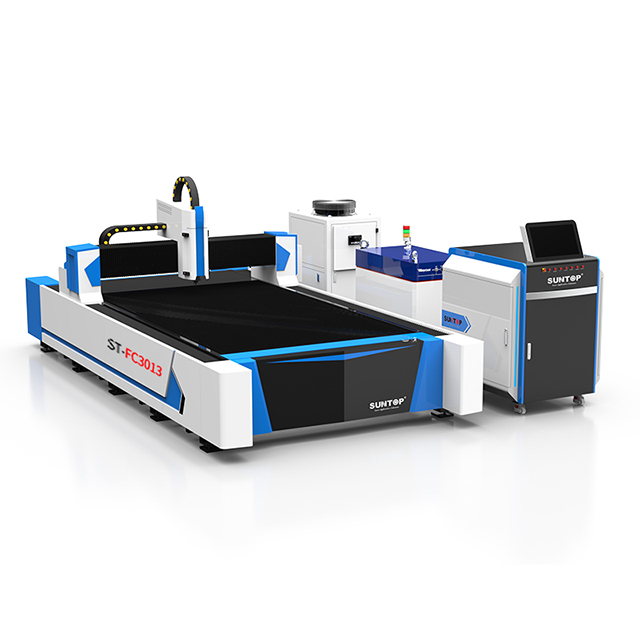

Parameters of Single table fiber laser cutting machine

Machine model | ST-FC3015/ ST-FC3013/ ST-FC4020/ ST-FC6015/ ST-FC6025/ ST-FC12025 |

Working area | 3000*1500mm (3000*1300mm/ 4000*2000mm/ 6000*1500mm/ 6000*2500mm/ 12000*2500mm) |

Laser power | 1000W-20KW |

Transmission system | Double rack & pinion and servo drive |

Maximum speed | 60m/min |

Positioning accuracy | ±0.03mm/1000mm |

Repositioning accuracy of clamp | ±0.02mm/1000mm |

Format | LXD, DXF, PLT, AI, NC etc. |

Working environment | 0-45℃, Humidity ≤ 80%, non-condensing |

Equipment power | 8KW (not include laser generator and chiller) |

Power supply | Three phase 380V/50Hz or 60Hz |

Total weight | 3000Kg |

Overall size | 5010*2260*1900mm |

Fiber laser cutting machine samples