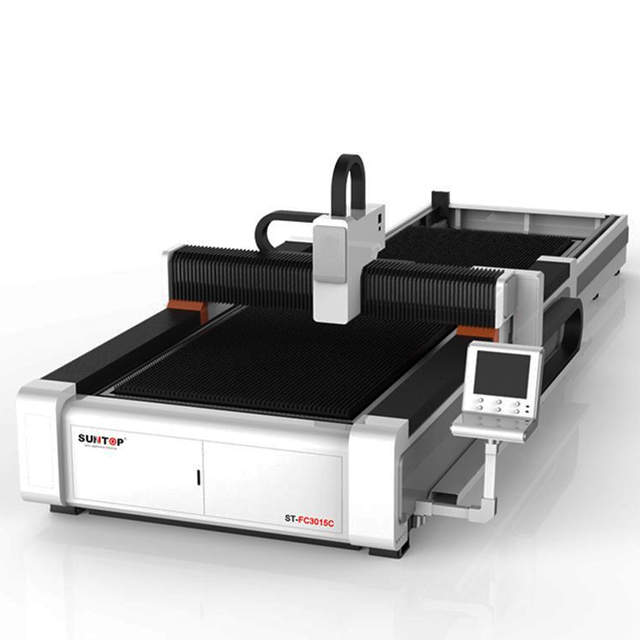

Details Product Parameters Samples Video

Features of open type dual exchange platform laser cutting machine

1. This machine adopts an up and down exchange platform, simultaneous loading, unloading and cutting of panels greatly increases work efficiency.

2. The converter is responsible for controlling the exchanging motor, the machine is able to finish the platform exchanging within 15s.

3. Imported transmission mechanism and servo motor, and high cutting accuracy.

4. Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation.

5. Automatic following system, can realize a calibrating, automatics following for wave surface sheet metal.

6. Heavy-duty machine structure with cross-welded steel plates to support later laser power upgrades.

7. The design of the exchanging structure of the table and the height of the saw teeth enables this machine can be installed the sheet metal automatic loading and unloading system.

Details of open type dual exchange platform laser cutting machine

1. Heavy duty machine tool

The whole machine is made of thick carbon steel structure, and the weight of single machine tool is up to 4 tons. The hollow structure of the high-power machine effectively reduces the heat area during the laser cutting process. The machine tool will not be deformed in long-term use, and also ensures good cutting accuracy, which greatly improves the stability of the machine. At least 20 years of use will not be deformed.

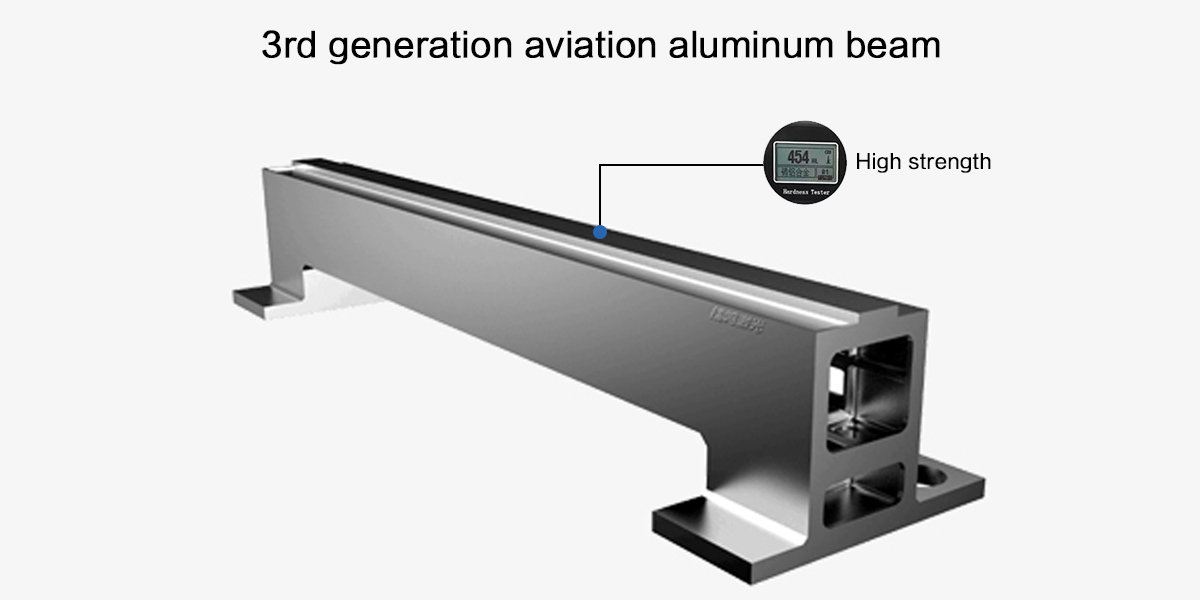

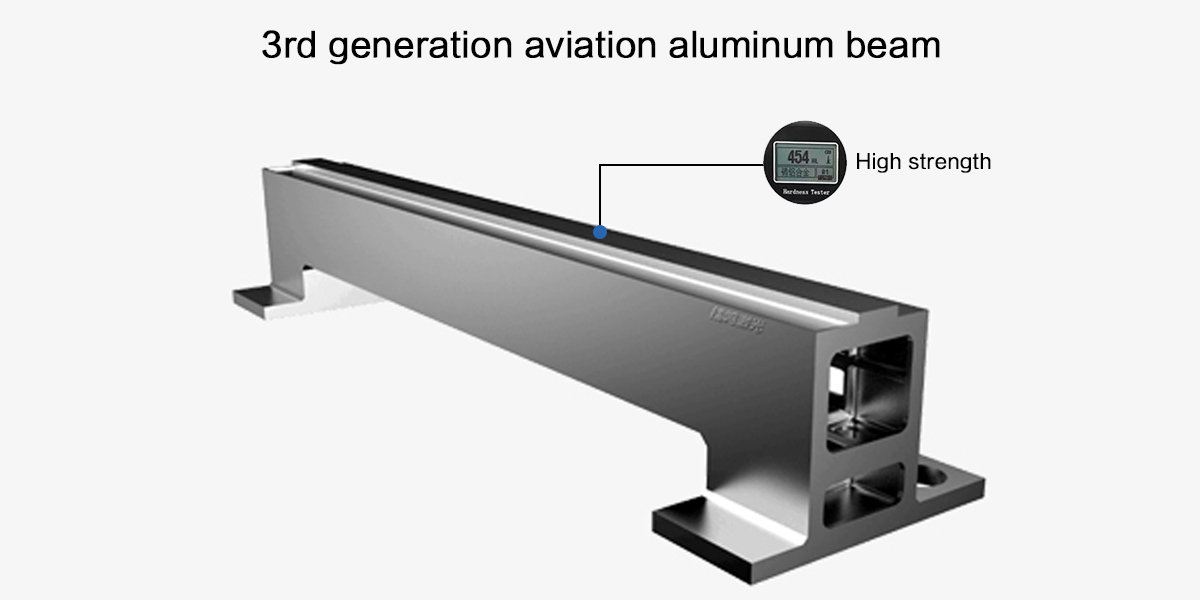

2. 3rd Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

3. Suntop patented design universal shaft drive exchange platform

Good synchronization performance, high exchange torque, strong overload resistance, long-term reliable operation without failure. Equipped with high power mid-mounted 3KW motor with brake system and hardened gear reducer, large torque output, symmetrical 80mm diameter universal shaft torque transmission, double 16mm chains to drag the table.

4. Imported original fiber laser source

Famous brand Raycus, IPG, MAX fiber laser, stable performance, service life can reach 100,000 hours, the overall quality of the equipment is guaranteed.

5. France Schneider original MCB relay

Independent control of each control circuit, using multiple Schneider air circuit breakers, not subject to strong electrical interference. Industrial grade industrial control host, software system runs stable and smooth without crashing.

6. Suntop laser cutting head lift (Z-axis)

Adopt closed module, fully sealed and protected, effectively prevent cutting dust and smoke from entering the module, avoid and reduce malfunction. Internal integration of ball screw and linear guide, etc., with high integration, small size and high operating accuracy.

7. Stainless steel protective organ cover

It can effectively prevent the cutting sparks from burning the organ cover and fully and effectively protect the guide rack from mechanical dust and foreign objects.

Advantages of open type dual exchange platform laser cutting machine

1. Independent high and low double worktable, fast exchange speed, saving loading and unloading time.

2. High precision, fast speed, narrow kerf, minimum heat-affected zone, smooth cutting surface without burrs.

3. Non-contact cutting, the cutting edge is slightly affected by heat, basically no thermal deformation of the workpiece, and no secondary processing is required.

4. Save costs, maximize the use of materials, and do not need molds.

5. Safety and environmental protection, less waste in laser processing, low noise, clean, safe, and pollution-free, greatly improving the working environment.

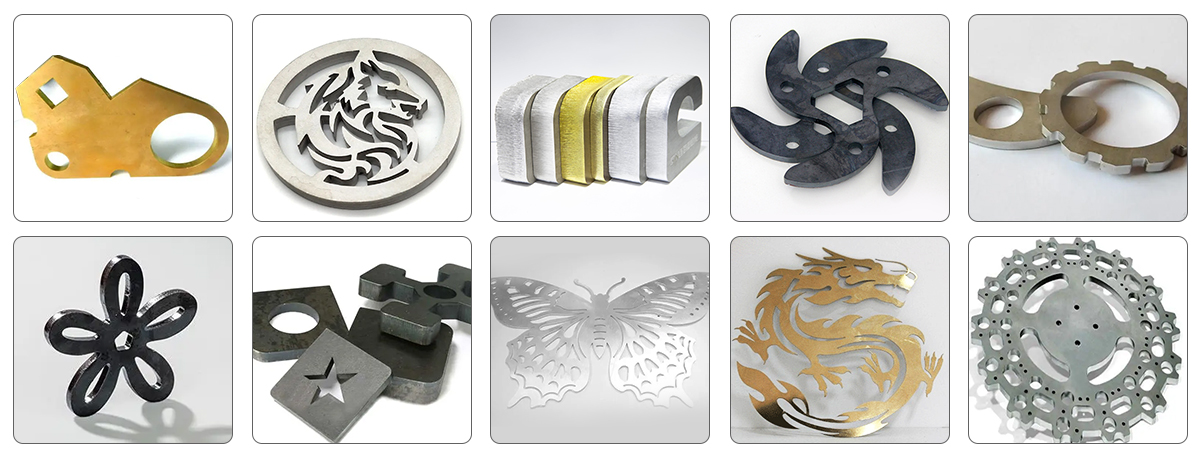

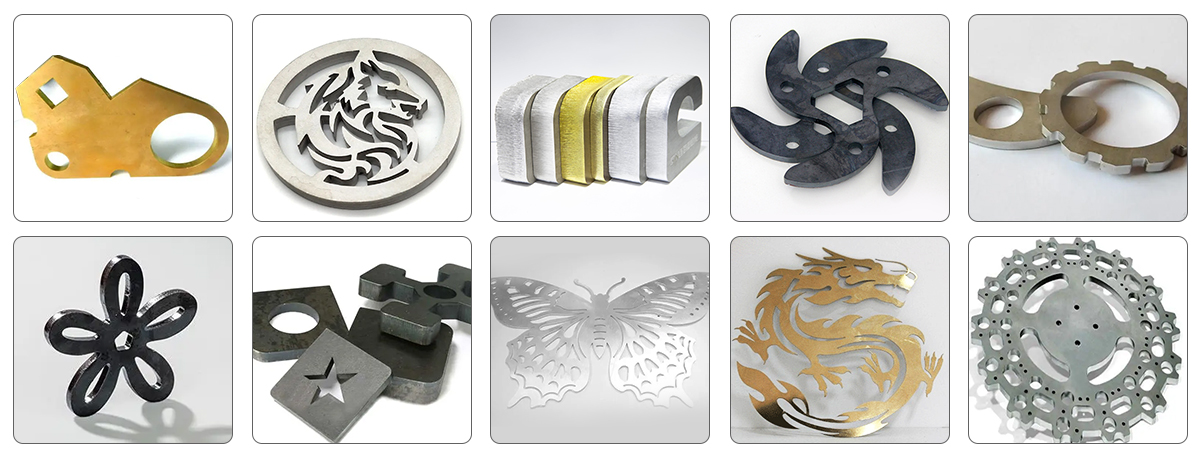

Dual exchange platform laser cutting machine application

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, alumina-plating, zinc plate, metallic copper, brass and other kinds of metals.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industry.

Parameters of open type dual exchange platform laser cutting machine

Model | ST-FC3015C/ST-FC4020C/ST-FC6015C/ST-FC6020C |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 6000*1500mm, 6000*2000mm) |

Laser wavelength | 1064nm |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Maximum speed | 120m/min |

Repeat positioning accuracy | ±0.02mm |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Power consumption | <10KW |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | Three phase 380V/50Hz or 60Hz |

Machine weight | 5000KG |

Machine volume | 37m³ |