Details Product parameters Samples Video

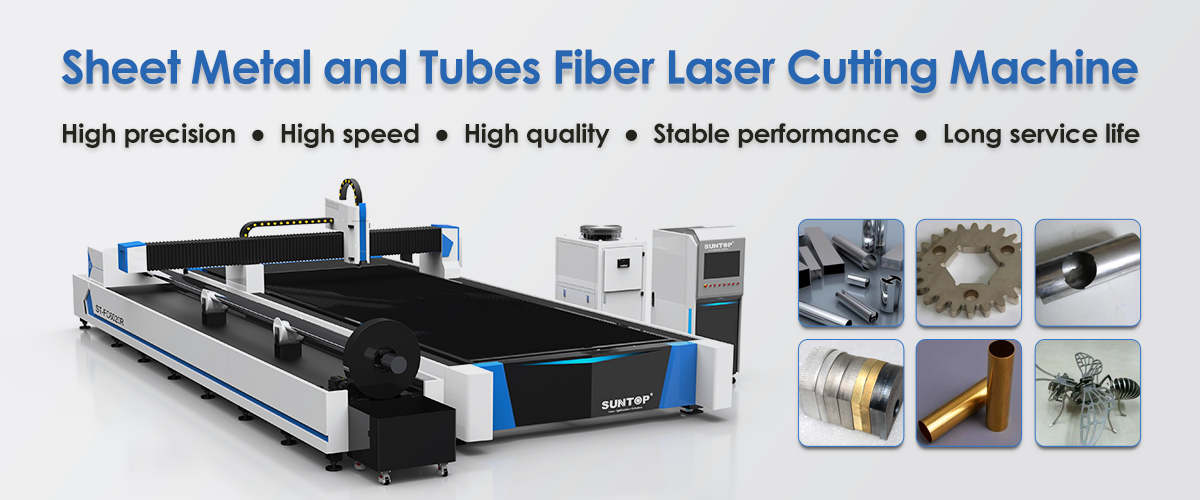

Main functions of sheet metal and tubes laser cutting machine

1. Capable of cutting a number of cylindrical coherent bores in different directions and diameters in the main pipe to meet the conditions of vertical intersection of the branch pipe axis with the main pipe axis eccentrically and non-eccentrically.

2. be able to cut cylindrical coherent line ends in branch pipe ends to satisfy the condition of vertical intersection and inclined intersection of the branch pipe axis with the eccentric and non-eccentric axis of the main pipe

3. be able to cut diagonal truncated ends on round pipe ends

4. be able to cut welded elbows on circular pipes, with "shrimp joints" with oblique cut-off sections at both ends.

5. be able to cut the end of a branch pipe intersected by a ring main.

6. Capable of cutting variable angle bevel faces.

7. Able to cut square and waist-shaped holes in round tubes.

8. Able to perform steel pipe truncation.

9. Able to make various shapes in square tube faces.

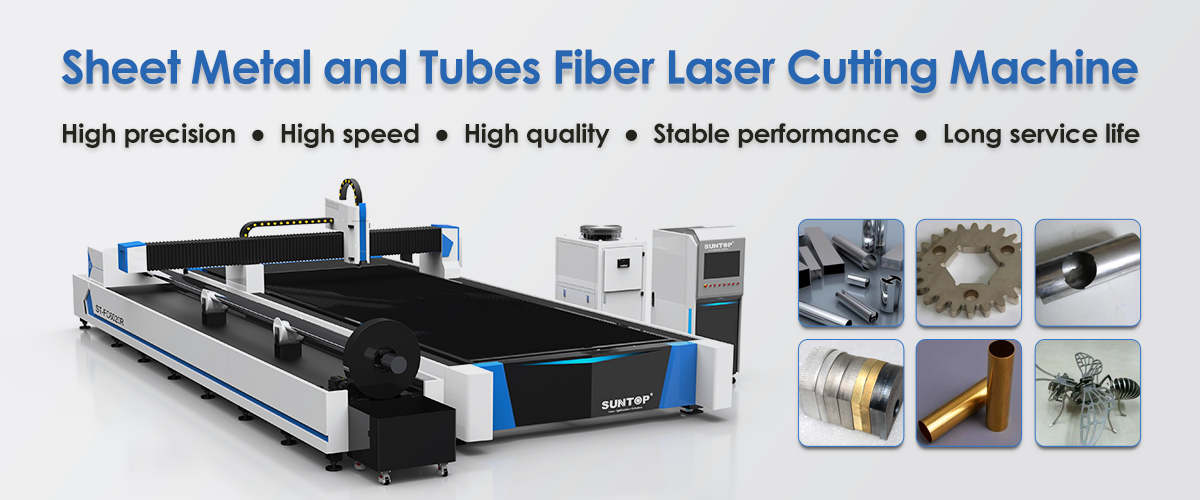

Features of sheet metal and tubes laser cutting machine

1. With CYP tube cutting software, drawings from 3D drawing software to 2D drawing software can be accepted directly. Drawings can be displayed directly on the computer for added convenience and immediacy.

2. High performance, imported original packaged fiber laser with stable performance and a life expectancy of over 100,000 hours

3. Electric automatic centering chuck, no need for manual adjustment, no need to adjust the center for any material from 20-150mm diameter

4. The machine adopts servo motor drive system for both front and rear chucks and drills, cutting without jitter, high precision and good synchronization.

5. One machine has two cutting functions, not only for sheet metal, but also for different types of metal pipes. More than 50% of space can be saved, effectively increasing the productivity of the end user.

6. Automatic following system for calibrating and automatically following wavy metal sheets.

Details of sheet metal and tubes laser cutting machine

1. Fiber laser source

Raycus, MAX, IPG and other brands of fiber optic lasers are used, with good spot quality, stable output power and a long service life of 100,000 hours, with a wide range of power options.

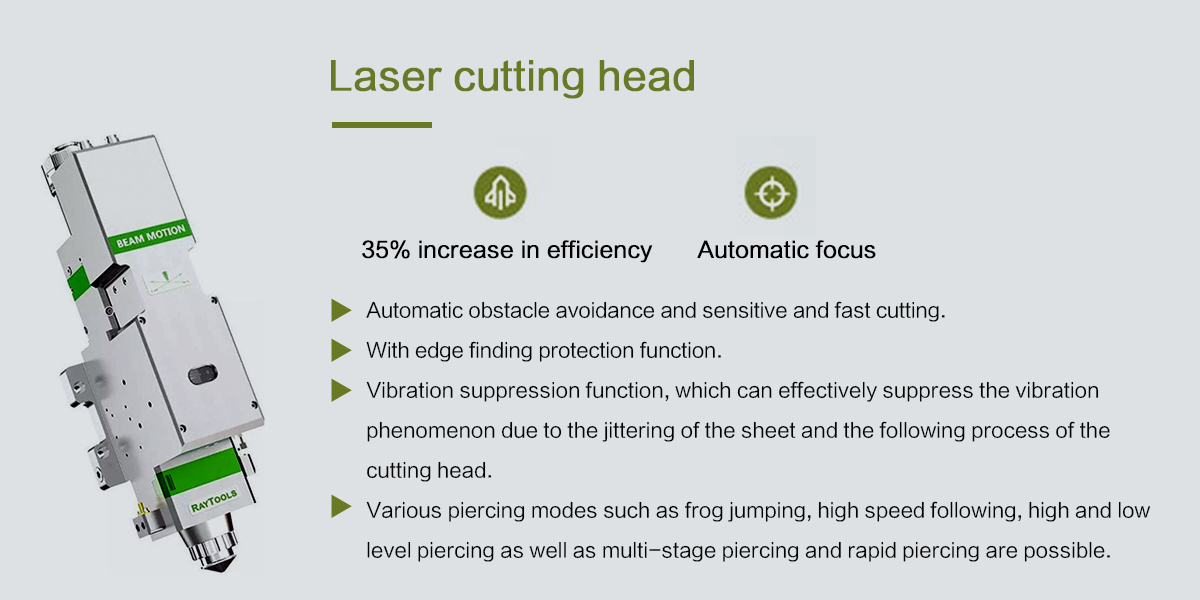

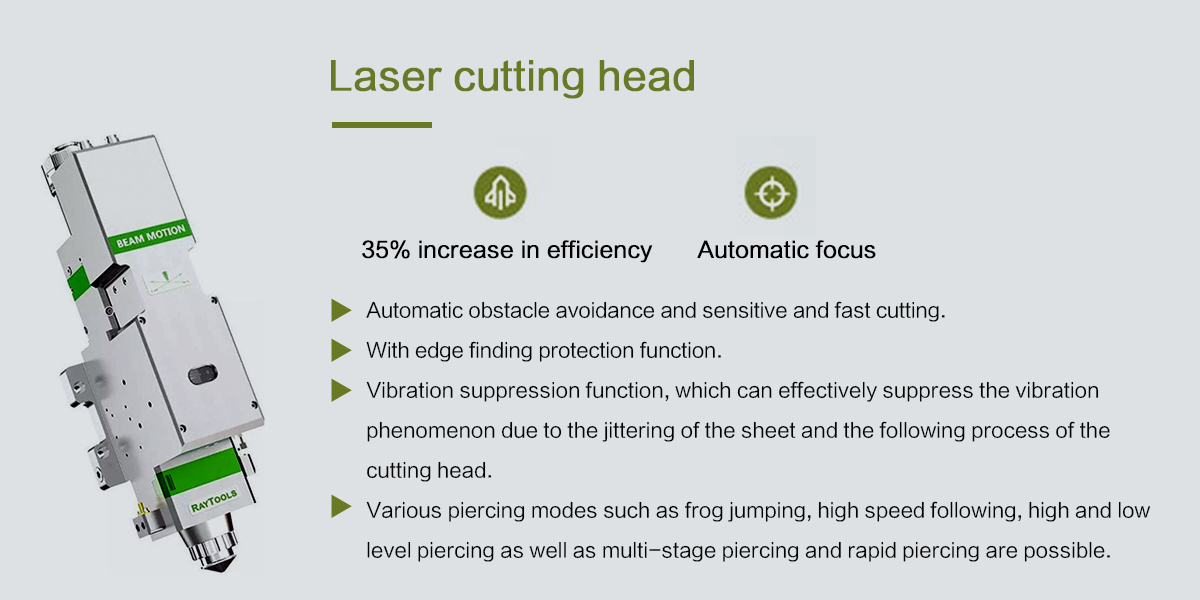

2. Automatically adjusts the laser head

The focus scale can be adjusted flexibly, without manual focus adjustment, and the operation is convenient. Control the vertical height, auto-focus, quickly complete the high-speed perforation of thick plates and automatically cut materials of different thicknesses.

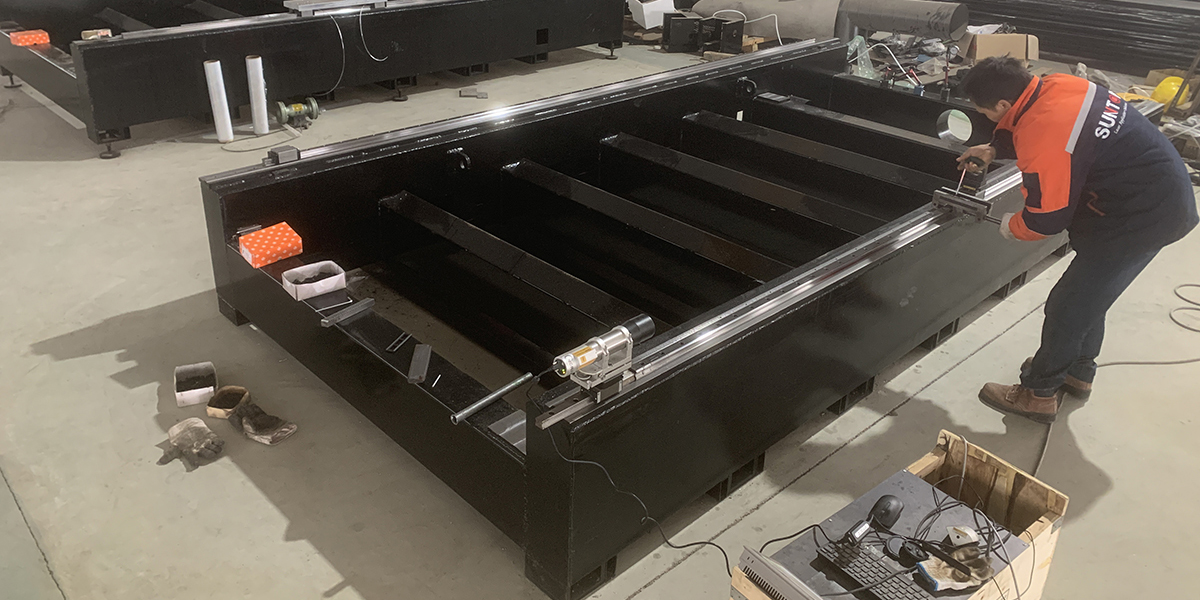

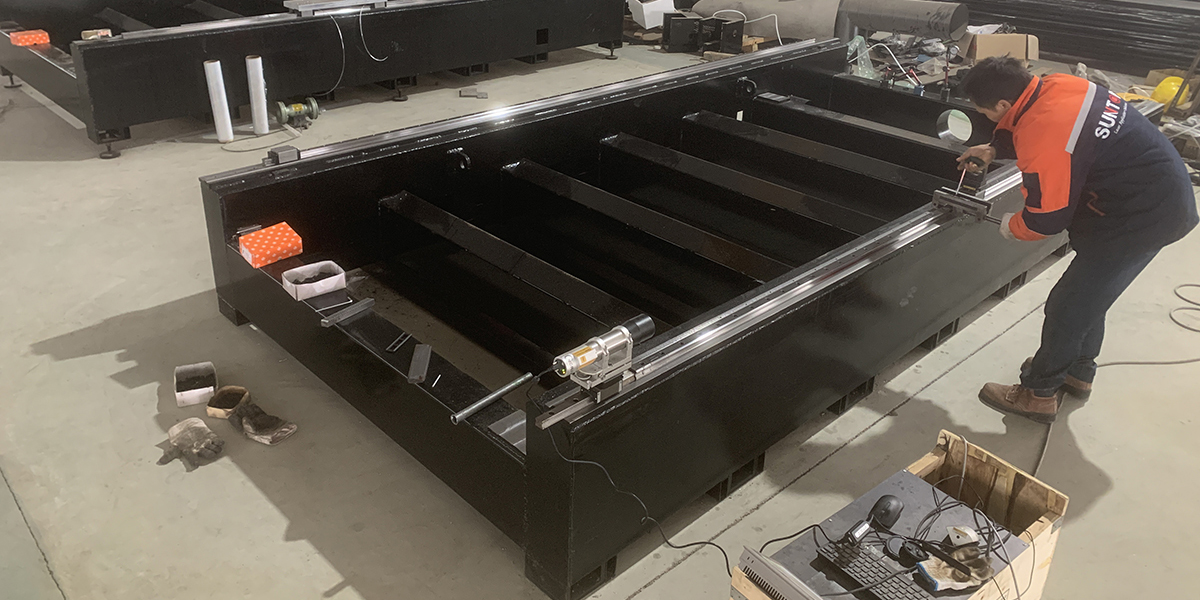

3. Machine tool

The bed adopts integral welding structure, which is rough machined after annealing to eliminate internal stress, and finished after secondary vibration aging treatment, which greatly improves the stability of the machine tool. The upper side of the main beam of the bed is paved with composite armor, which can effectively improve the impact of the high temperature generated during high-power laser cutting on the overall structure of the machine frame; there is a smoke outlet under the bed, and the smoke is automatically smoked through the smoke exhaust pipe, which can make the cutting process The smoke and dust generated can be easily discharged outdoors, which improves the working environment; the entire working area adopts a fully enclosed cover, and the safety protection is reasonable.

4. Cast aluminum crossbeam

Integral cast aluminum crossbeam, refined by artificial ageing and solid solution treatment, gives the crossbeam excellent integrity and rigidity, as well as good toughness.

Light weight, corrosion and oxidation resistant, low density, fast cutting of all types of graphics while meeting accuracy.

5. High-quality guideways and rack and pinion transmission

High rigidity, smooth running, low noise, smooth running, shock and vibration mitigation.

6. Automatic lubrication system

Timed and quantitative lubrication system for equipment, not controlled by position direction, reducing equipment maintenance time.

Accelerates machine automation and extends the life of the drive mechanism.

Equipped with an independent warning system to provide early warning functions.

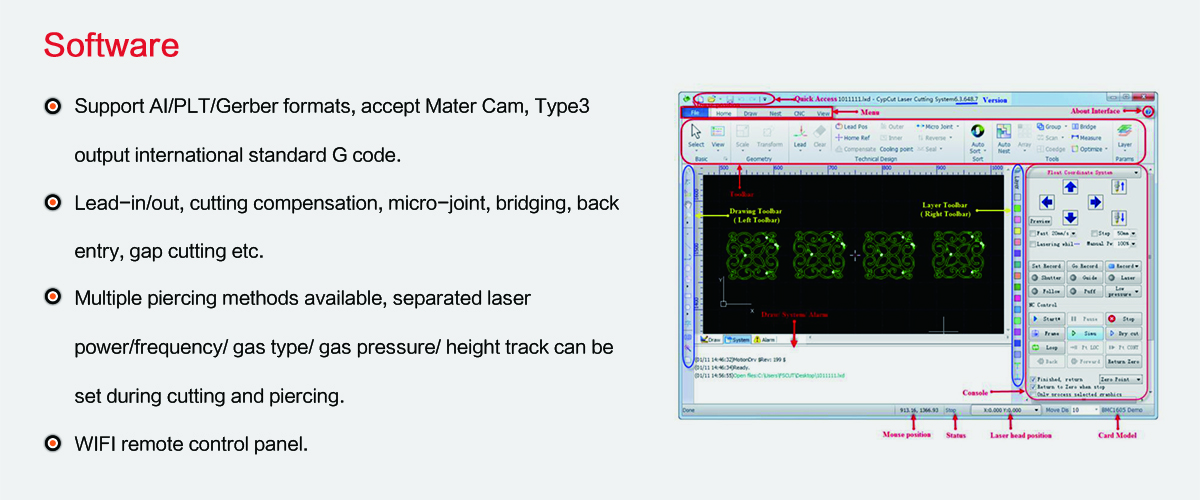

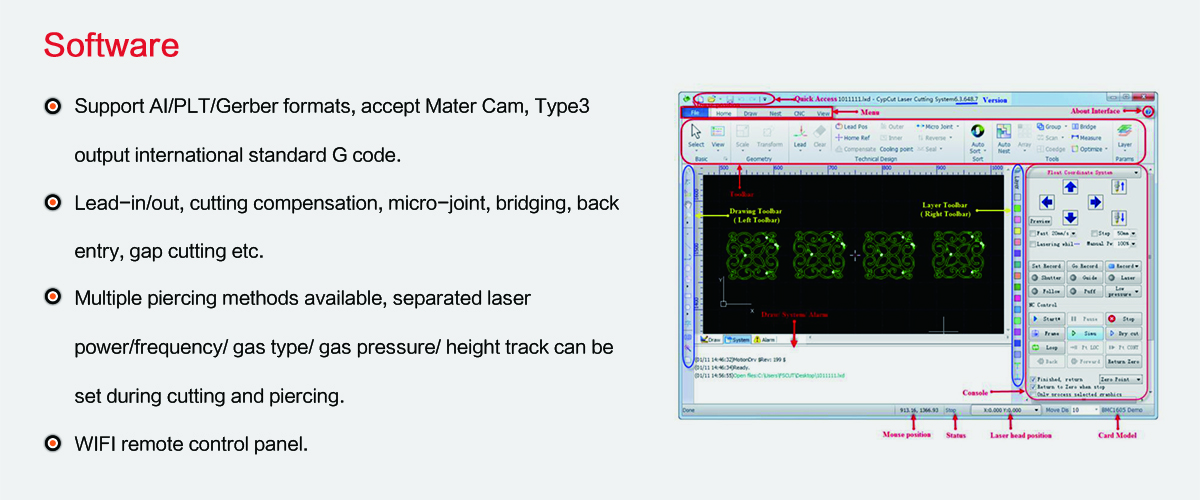

7. Professional software operating system

The use of a professional can design various graphics or text at will, facilitating the editing and modification of cutting paths. Scientific human-machine interface, flexible processing, simple operation and high efficiency.

Advantages of sheet metal and tubes laser cutting machine

1. Fast cutting speed, good quality, small cutting slit, small deformation, smooth, flat and beautiful cutting surface, no need for follow-up treatment.

2. Large working width with pipe cutting device, can cut flat plate as well as round pipe, more applicability, can eliminate the opening process, suitable for mass production, high efficiency, high stability performance.

3. High cutting accuracy, more suitable for precision parts processing and various fine crafts cutting.

4. The perfect numerical control system and professional auxiliary control software make the work flexible, high efficiency, simple and convenient machine operation.

5. The laser equipment is installed with a focal distance automatic tracking adjustment system, which can easily complete the cutting of distorted and deformed materials.

6. The whole laser cutting machine adopts servo motor and precision guide rail, which makes the cutting accuracy high, stable and longer life.

7. In the cutting of tubes more prominent its advantages, cutting process is exquisite, precision and accurate.

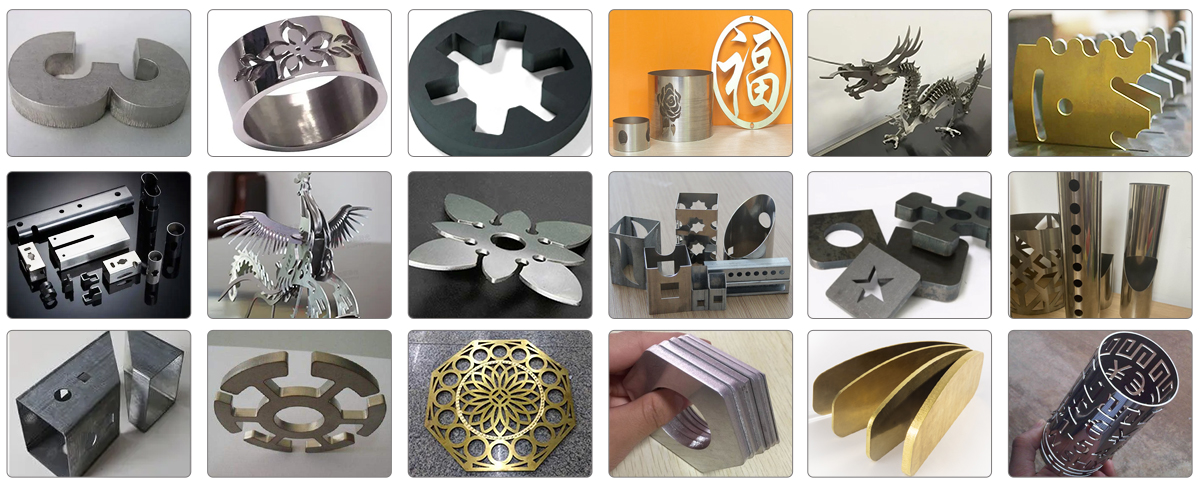

Sheet metal and tubes laser cutting machine application

Application materials

Mainly cutting a variety of metal plates and tubes, suitable for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Application industry

Sheet metal processing, round and square pipes, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobiles, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industries.

Parameters of sheet metal and tubes laser cutting machine

Model | ST-FC3015R/ST-FC6015R/ST-FC6020R/ST-FC4020R |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (6000*1500mm, 6000*2000mm, 4000*2000mm) |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Maximum speed | 120meter/min |

Transmission system | Double rack & pinion and servo drive |

Tubes cutting capacity (standard) | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters |

Chuck type | Manual type or pneumatic self-centering chuck |

Maximum acceleration | 1.5G |

Power consumption | 6KW (based on laser power 1KW) |

Power supply | Three phase 380V/50Hz or 60Hz |

Machine weight | 7250Kg |

Overall size | 5050*2480*1830mm (L*W*H) |

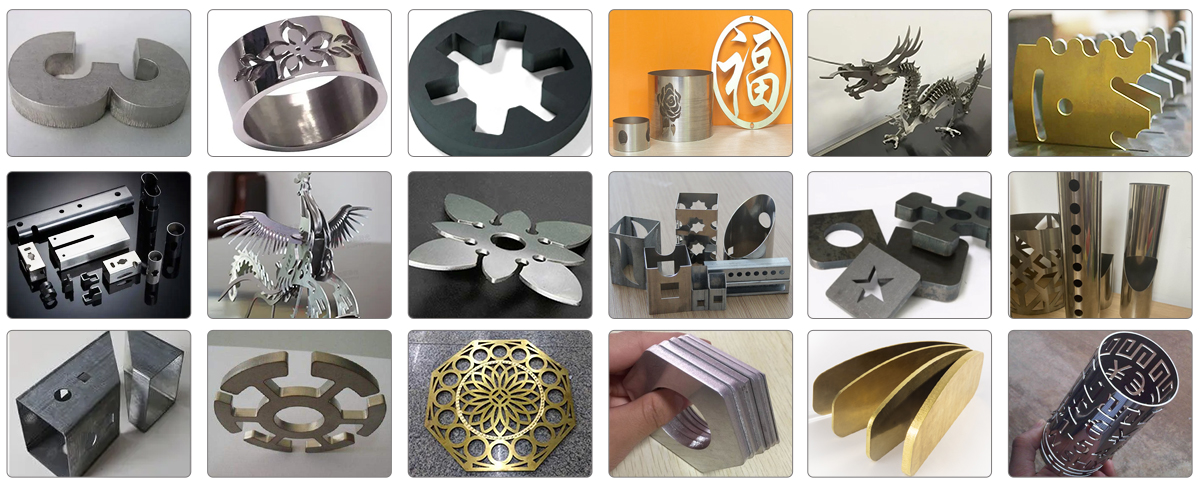

Sheet metal and tubes laser cutting machine sample