Details Product Parameters Samples Video

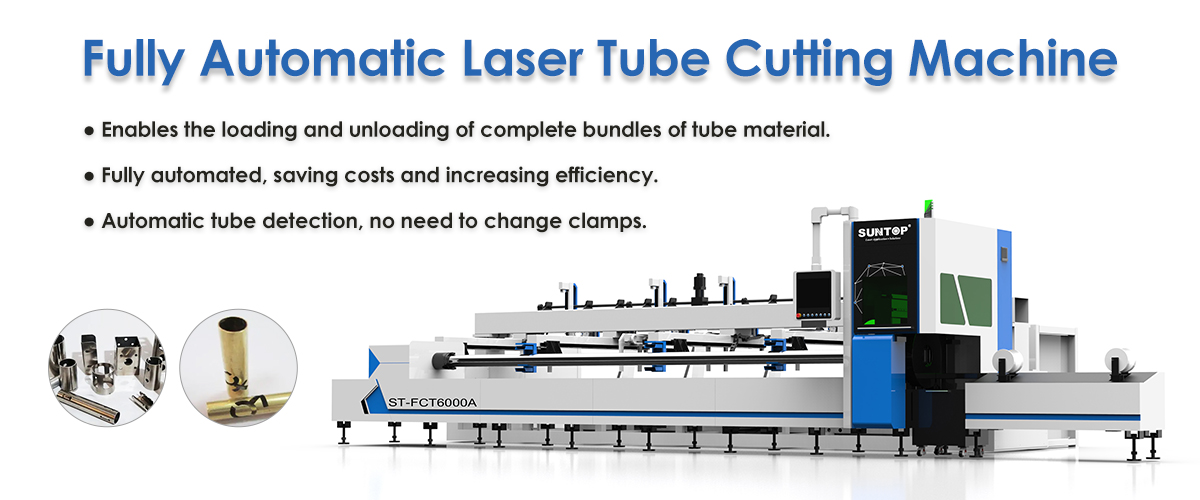

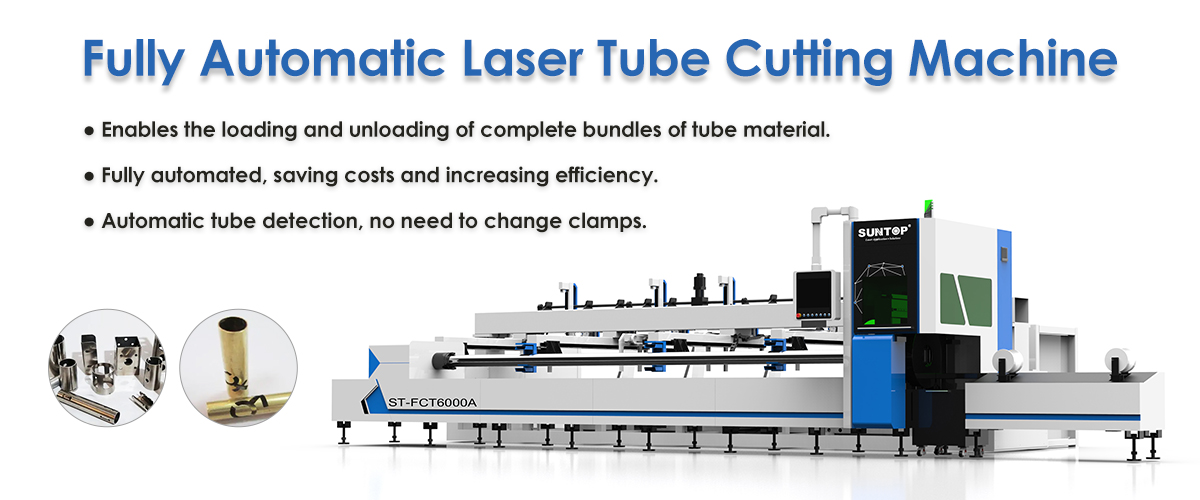

Features of laser tube cutting

1. The system includes automatic feeding and automatic unloading. The automatic feeding system is seamlessly connected with the laser pipe cutting machine through the numerical control system to realize the hoisting and feeding of the whole bundle of pipe materials.

2. The front and rear adopt double pneumatic chuck design, and the rear chuck is equipped with an air blowing device to reduce the slag attached to the pipe wall during the cutting process.

3. Intelligent pipe cutting design, pneumatic support, large load capacity, and helical gear transmission can effectively reduce the noise and vibration caused by gear engagement during chuck transmission, ensuring the stability of cutting.

4. High performance, using imported packaged fiber laser, stable performance, good beam quality, high precision, life span up to 100,000 hours.

5. The automatic unmanned working cycle, with the help of fast loading and unloading function, makes the machine tool have a high utilization rate.

6. Chuck diameter and fixture can be customized according to the specific specifications of the pipe provided by the customer.

Details of laser tube cutting

1. Clamping design

Driven by a motor, the front and rear are clamped by electric chucks, the center is automatically adjusted, the clamping range is wide, and the operation is simple and stable.

Gear transmission mode, higher transmission efficiency.

2. Heavy bed design

A high-power machine tool with a hollow structure is welded with thick steel plates, and the weight of a single machine tool reaches 4 tons. Effectively reduce the heated area during laser cutting. Long-term use of the machine tool will not deform, but also ensure good cutting accuracy, greatly improving the stability of the machine. It will not be deformed after at least 20 years of use.

3. Laser cutting head

No need to manually focus, the software automatically adjusts the focusing lens. Control the upper and lower heights to realize automatic perforation and cutting of plates with different thicknesses. Automatic adjustment of the focus lens is ten times faster than manual adjustment.

4. Fully automatic loading and unloading device

Automatic feeding

After the whole bundle of pipes enters the feeding device, it realizes intelligent material separation and loading, and seamlessly connects with the fiber laser cutting machine to ensure that only one pipe is transported to the conveying arm at a time.

automatic uninstall

The finished product automatically falls into the silo, and the double support bearing assists in supporting the super long tube

5. Automatic stroke protection

Detect the whole process of cutting head work, quickly feedback the risk and stop. Fixed limit double protection, improve equipment and personal safety, reduce risks

6. Intelligent alarm system

Detect anomalies in advance, reduce hidden dangers, and double the effect of equipment anomaly detection.

Advantages of laser tube cutting

1. The whole machine is highly integrated, with good system performance and long service life.

2. Automatic loading and unloading, double the efficiency and greatly save labor costs.

3. The chucks clamping each other can automatically detect the pipe material, and there is no need to replace the fixture when changing various pipe materials. The cutting accuracy of the pipe can be precisely controlled.

4. The thermal shock of laser cutting pipe is small, not easy to deform, the cutting surface is smooth and beautiful, and no secondary treatment is required

5. Modular design, can be customized according to customer needs.

Laser tube cutting application

Application materials

Mainly cutting a variety of metal tubes, suitable for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Application industry

Widely used in sheet metal processing, round and square pipes, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobiles, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industries.

Parameters of laser tube cutting

Model | ST-FCT6000A/ST-FCT3000A |

Laser power | 1000W-20KW |

Laser wavelength | 1064nm |

Elector-optical conversion efficiency | 25%-30% |

Cutting thickness | 0.5-30mm (depend on the actual laser power) |

Cutting seam width | 0.1-1.3mm (depend on the actual thickness of metals) |

Repeated positioning accuracy of the machine tool | ±0.02mm/1000mm |

Positioning accuracy of the machine tool | ±0.03mm |

Max. idle moving speed | 100meter/min |

Max. acceleration | 1.2G |

Max. loading weight | 3000KG |

Single pipe Max. weight | 100KG (when air pressure is 6 bar, every meter≤16KG) |

Tailing length | ≥160mm |

Pipe processing range | 20mm≤Round pipe≤210mm, square pipe (20mm-150mm) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 9000KG |

Machine dimension | 12000*2450*2400mm (L*W*H) |