Laser cutting is now recognized as one of the metal processing methods with high efficiency, high quality and high precision. There are many factors affecting laser cutting, and nozzle is one of them. Choosing the right nozzle when cutting all kinds of materials can make processing easier, how to correctly choose the right nozzle? Today we will take a look together.

The nozzle, also known as copper nozzle, is one of the very important parts in laser cutting. The nozzle is located at the low end of the cutting head, the laser beam and auxiliary gases are through the nozzle effect on the cutting material, its main role is: gathering auxiliary gases and the formation of high-pressure, released to the surface of the cutting material and the slit, blowing away the cutting process produced by the melting and vaporization of the parent material, leaving a clean slit; at the same time, to stop the slag, smoke and other pollutants to the upward rebound, and then to protect the internal lenses.

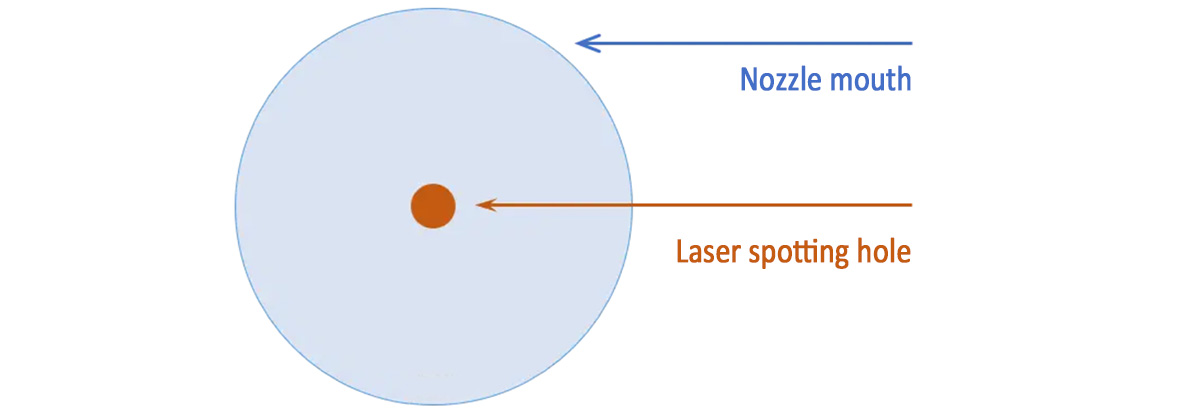

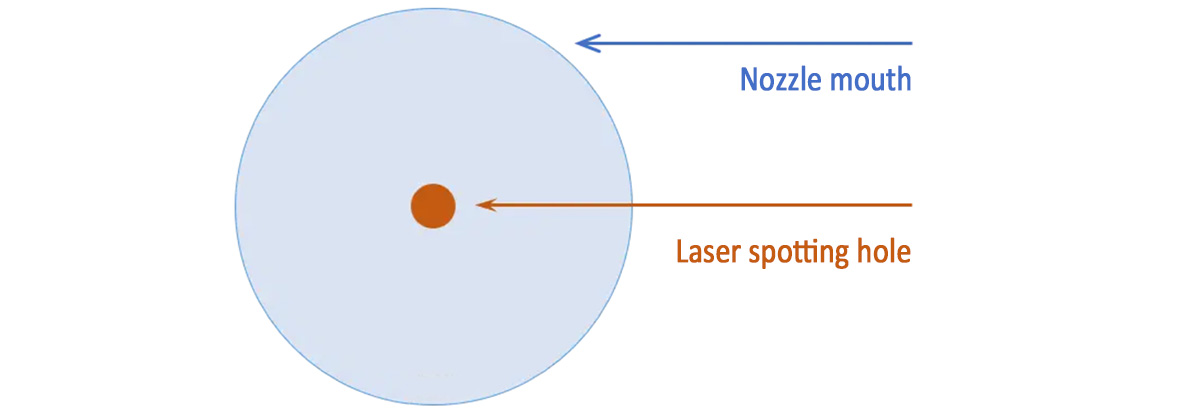

To get a better cut section, you need to control the concentricity of the laser beam with the center of the nozzle, the center of the nozzle and the laser beam

The concentricity between the center of the nozzle and the laser beam is one of the most important factors affecting the quality of the cut. Therefore, it is necessary to make the center of the nozzle and the laser beam coaxial in order to obtain a better cutting section.

When the center of the nozzle and the center of the laser beam have different axes, the effect on the cutting quality:

1. Cutting gas from the center of the nozzle, the center of the nozzle is the center of the plate needs to be cut off, if the laser is not in the center of the nozzle, the laser action point and the actual deviation will occur, there will be a cutting of the actual and expected effect is obviously inconsistent with the phenomenon.

2. If the laser is not in the center of the nozzle, the normal operation of the beam will hit the inner wall of the nozzle, the seriousness of the nozzle will be burned, affecting the actual effect of cutting.

Verify that the laser beam and the nozzle is concentric and coaxial, you need to test the following steps:

1. in the nozzle mouth to paste transparent tape, the round edge and the tape completely overlap;

2. Adjust the power of the equipment to about 100W, and use the point-blank mode of laser irradiation on the transparent tape;

3. Remove the transparent tape, observe the circular edge and the position of the laser perforation relationship.

If the perforation is in the center of the circle, it means that the laser beam is concentric and coaxial with the nozzle, no need to adjust; if the small hole and the center of the circle is not the same axis, or you can not see the small hole (the laser beam on the inner wall of the nozzle), you need to adjust the adjustment screws on the laser cutting head, and repeat the above steps 1-3 until the laser perforation point and the center of the nozzle coincide.

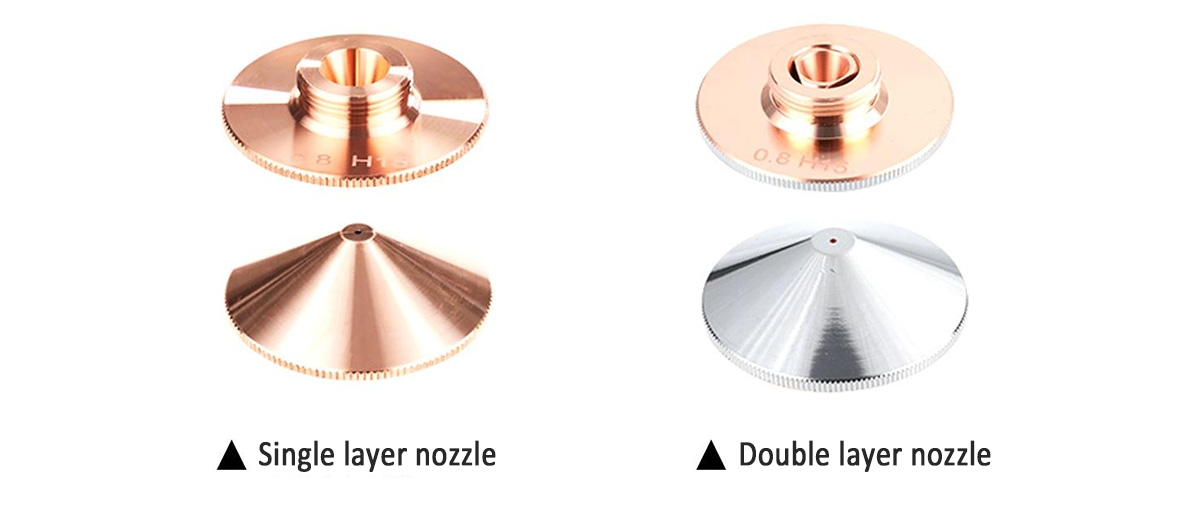

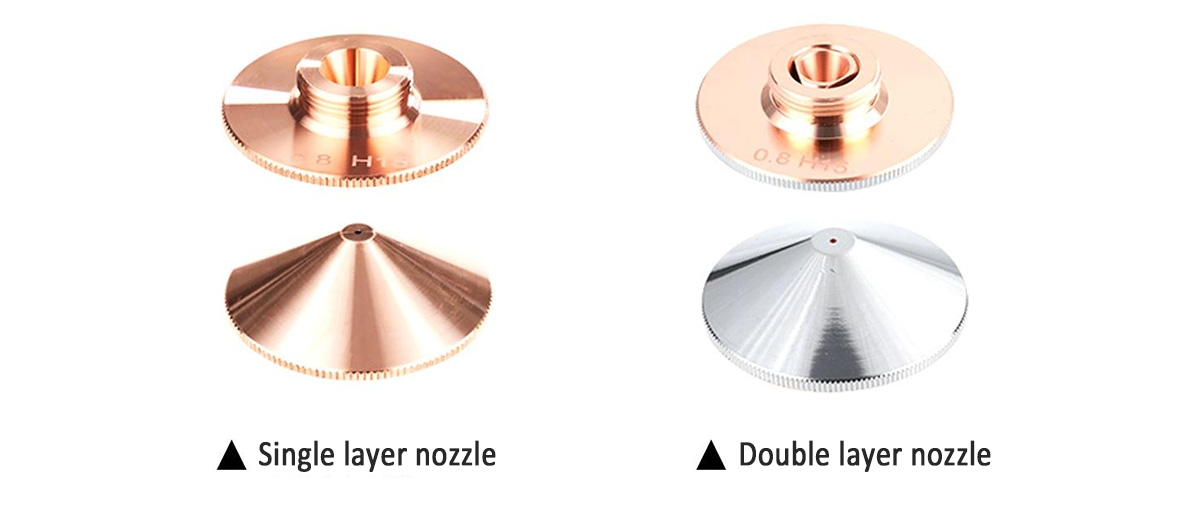

Selection of nozzle type:

Nozzles are categorized into single-layer and double-layer nozzles. Single-layer nozzle relative gas flow rate is slow, commonly used in cutting stainless steel, aluminum alloy, copper and other metals, mostly using nitrogen as an auxiliary gas. Double-layer nozzle gas flow rate is fast, suitable for high-speed cutting, commonly used in cutting carbon steel, generally use oxygen as an auxiliary gas, the cutting surface will usually be blackened by oxidation.

Nozzle size selection:

The size of the nozzle caliber determines the gas flow rate acting on the cut material, which in turn affects the molten material removal. The higher and faster the gas flow rate into the cut, the greater the ability of the jet to remove melt.

Theoretically, the thicker the plate, the larger the nozzle should be used. However, the larger the hole diameter of the nozzle, the greater the chance that sparks from the molten material will splash and bounce upward during cutting, making the life of the lens shorter.

If the nozzle is deformed or if there are melt stains on the nozzle, the cutting effect will be affected. Therefore, the nozzle should be carefully placed so as not to be bruised or deformed, and the nozzle should be cleaned in time when it is stained with melt.