Laser cutting technology plays an extremely important role in modern manufacturing. Here are some key aspects of its importance:

1. High efficiency and high precision

Fast cutting: Laser cutting has an extremely high cutting speed and can complete the cutting of complex patterns in a short time, which is suitable for large-scale production.

High precision: Laser cutting can achieve micron-level cutting accuracy, smooth cutting edges, and no subsequent processing is required, ensuring product quality and consistency.

2. Wide range of material adaptability

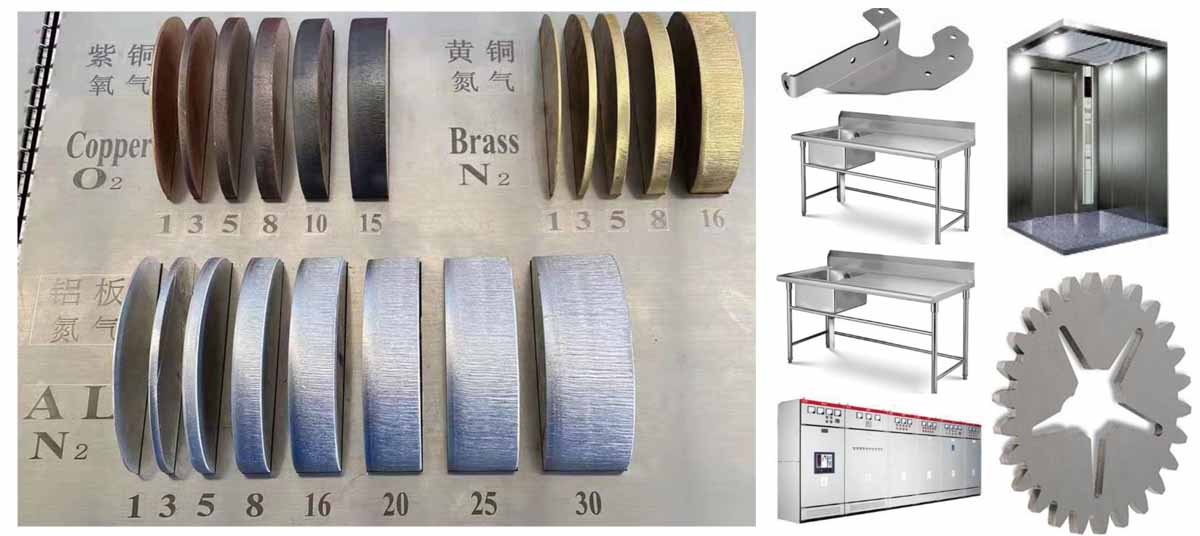

Diverse material processing: Laser cutting can process a variety of metal materials, including stainless steel, aluminum, copper, etc. Its flexibility meets the requirements of different industries for different materials.

Market segmentation needs: Able to cope with the characteristics of various materials (such as thickness, reflectivity, etc.), laser cutting provides suitable solutions for applications in specific industries (such as automobiles, aviation, electronics).

3. Reduce production costs

Reduce material waste: The precise control and efficient cutting process of laser cutting greatly reduce material waste, thereby reducing overall production costs.

Low maintenance costs: Compared with traditional cutting technologies, laser cutting equipment has lower daily maintenance requirements, reducing downtime and repair costs.

4. Automation and Intelligent Manufacturing

Integration with CNC: Laser cutting technology is often combined with computer numerical control (CNC) systems to achieve automated cutting. This integration improves production efficiency and reduces human errors.

Data-driven optimization: Through data collection and analysis, manufacturing companies can continuously optimize the cutting process, achieve intelligent manufacturing, and improve production flexibility and responsiveness.

5. Environmental protection and sustainability

Low energy consumption and less waste: Laser cutting technology produces less waste during the cutting process and involves lower energy consumption, which is in line with the environmental protection concept of the modern manufacturing industry.

Promote green production: Companies that adopt laser cutting technology can reduce the burden on the environment while meeting the growing requirements for sustainable development.

6. Promotion of technological innovation

Development of new applications: The continuous advancement of laser cutting technology has broadened its application range in various industries, such as medical devices, aerospace, electronic components, etc.

Processing of advanced materials: With the continuous emergence of new materials and technologies, laser cutting provides new processing solutions for processing these new materials and promotes technological innovation.

As an efficient, flexible and precise processing technology, laser cutting occupies a pivotal position in modern manufacturing. It not only improves production efficiency and reduces costs, but also meets the demand for ever-increasing product quality. In the context of the increasing importance of environmental protection and sustainability, the application prospects of laser cutting technology are even more exciting. Click here for more information now