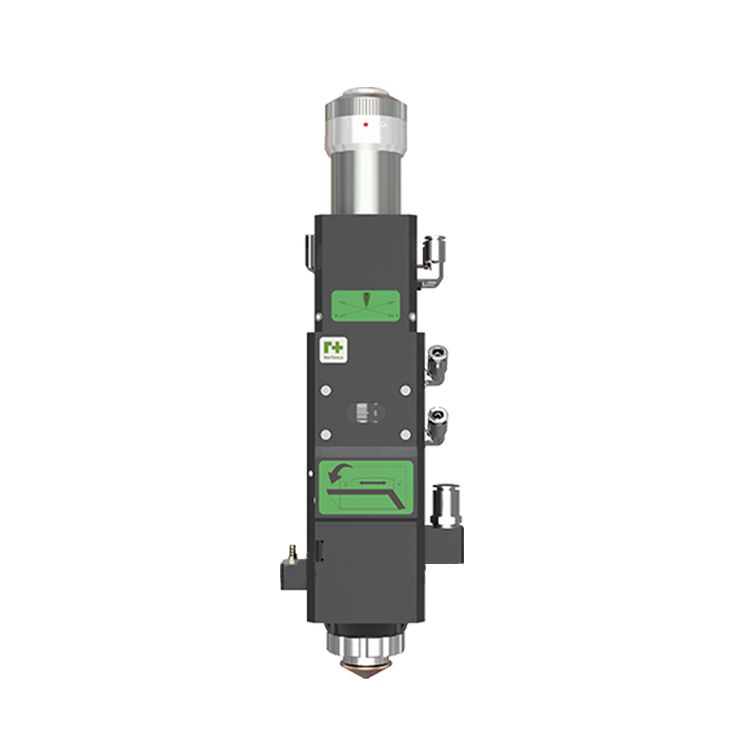

Product description

Swiss RAYTOOLS is an automatic focusing fiber cutting head. This product has an external servo motor with a built-in drive unit that drives the focusing lens through a linear mechanism to automatically change its position within a range of about 22mm. Users can set the continuous focus through the program to complete rapid perforation of thick plates and automatic cutting of different thicknesses and materials. Plate. This product can be equipped with a composite lens group to integrate the beam, and the diversified interface positions allow it to be used with various fiber lasers; the optimized optical and water-cooling design allows the laser head to work continuously and stably at high power for a long time.

Product features

1. Optimized optical configuration and smooth and efficient airflow design.

2. Automatic focusing range +10~-12mm, adjustment accuracy 0.05mm.

3. All lines and air pipes are routed from the inside to avoid unnecessary collision and damage.

4. The maximum acceleration of the focusing lens drive is 10m/s², and the maximum speed is 10m/min.

5. Using a drawer-type lens holder makes protecting lenses faster and easier.

6. Composite lenses are used for collimation and focusing to obtain optimal optical quality and cutting effects.

7. Equipped with QBH, QD, QCS, PAPI, LLK-D and other fiber interfaces to adapt to various fiber lasers.

Structural function

The laser head consists of four basic units: collimation module, focus drive module, protective mirror module, and nozzle.

● Collimation module: completes the optical fiber collimation function, collimates the incident laser into a parallel beam and has the centering function.

● Focus drive module: Focus the collimated beam into a high-power density convergent beam, and realize automatic adjustment of the focus position through the drive device.

● Protective lens module: The protective lens can protect the focusing lens from damage due to slag return and extend the service life of the focusing lens.

● Nozzle module: guides the focused beam to the workpiece and generates high-speed airflow to spray the cutting seam to complete high-quality cutting.

Product parameters

Laser head |

Rated power | Up to 4KW |

Focal length | 100mm、125mm、150mm、200mm |

Clear aperture | 25mm |

Nozzle diameter | 0.5-3mm |

Nozzle Specifications | Single layer, composite, porous, shower type, customized |

Cutting pressure | ≤20Bar |

Focus range | -5mm-+8mm |

Weight | 1.5KG |

Collimator |

Collimation focal length | 60mm、75mm、100mm |

Clear aperture | 25mm |

Fiber optic interface | QBH、QD、LLK-B、PIPA-Q |

Height sensor |

Sensing distance range (recommended 1mm) | 0.2mm-8mm |

Calibration | Automatic calibration |

Reaction time | <1ms |

Temperature stability | 0°~45°,±5° |

Power requirements | 24V |

Output (linear curve or optimized curve) | 0~10V analog |