Product Parameters Samples Video

Features of laser cutting machine for metal

1. High cutting precision and good stability: the precision ball screw transmission mechanism is adopted, and the control of the numerical control system is optimized, which can meet the precision parts processing, and the dynamic performance is stable, and it can work continuously for a long time.

2. Good quality of cutting section: Raytools cutting head is used, the cutting head moves with the height of the plate, and the position of the cutting point remains unchanged all the time, making the slit smooth and smooth, and the section does not need post-processing, which is suitable for cutting flat or curved plates.

3. The cutting format is large, suitable for cutting many materials, and widely used.

4. Core technology:

◆ The optical path system of the laser is stable. After thousands of vibration experiments, the optical path system of the laser is stable;

◆ Mechanical follow-up cutting head, purely mechanical transmission, stable and anti-interference.

5. The maintenance cost is low, and the photoelectric conversion efficiency is over 30%, which greatly saves power consumption during work, saves operating costs, and achieves the highest production efficiency.

6. Energy saving and environmental protection, equipped with professional dust removal equipment. Low noise, clean, safe and pollution-free.

Details of laser cutting machine for metal

1. The laser head actively avoids obstacles

Greatly reduce the probability of laser head hitting the board, reduce customer maintenance costs, avoid enterprise shutdown due to maintenance, and prolong the service life of the machine.

2. Intelligent anti-shake

The new generation of intelligent anti-shake function automatically adjusts the sensing sensitivity according to the degree of plate shaking to achieve stable cutting and improve processing efficiency.

3. Lightning Rapid Pierce

Lightning-like piercing experience and visual impact The cutting head moves into place, starts piercing, and completes the whole piercing process during the falling process, without additional actions and time.

4. One-key processing

Automatic edge finding, automatic processing, automatic exchange. Realize the perfect combination of man and machine, greatly improving production efficiency.

5. Automatic lubrication

Automatically lubricate the guide rails of each axis to ensure the stable operation of the equipment for a long time

6. Thick plate welded structure bed

The high-power machine tool with hollow structure can effectively reduce the heating area during laser cutting. Long-term use of the machine tool will not deform, but also ensure good cutting accuracy, greatly improving the stability of the machine. It will not be deformed after at least 20 years of use.

7. Ultra-high tensile aviation aluminum beam

Anti-distortion, anti-overturning, and better mechanical properties; greatly improving the rigidity of the gantry beam to ensure the application requirements of "high speed, high precision, and fast response"; high-strength inner cavity design, anti-deformation, and effectively disperse internal and external stress.

8. French Schneider servo motor and driver

The world's leading automation technology realizes efficient processing. High cutting precision, good dynamic performance, long service life and stable operation.

9. Intelligent alarm

Detect equipment abnormalities in advance, push the abnormal points to the display interface through the control center, reduce potential safety hazards, and double the efficiency of equipment abnormality troubleshooting.

10. Safety and environmental protection, zero pollution

Fully enclosed structure, exclusive optical fiber wavelength visible protection window, standard dust removal system, etc., every detail is for you to have a safe and pollution-free production environment.

Advantages of laser cutting machine for metal

1. The cut surface is smooth without burrs, and the surface roughness of the cut is generally controlled within Ra6.5.

2. Non-contact cutting, the cutting edge is less affected by heat, basically there is no thermal deformation of the workpiece, avoiding the collapse of the edge formed when the material is punched and sheared, and the cutting seam generally does not require secondary processing.

3. The laser cutting head will not touch the surface of the material, so as not to scratch the workpiece.

4. Save mold investment, no mold is needed, and the production cost is reduced.

5. It can realize automatic cutting and nesting, which improves the utilization rate of materials, low production cost and good economic benefits.

6. High degree of automation, using computer programming, can cut products of different shapes to maximize the utilization of materials.

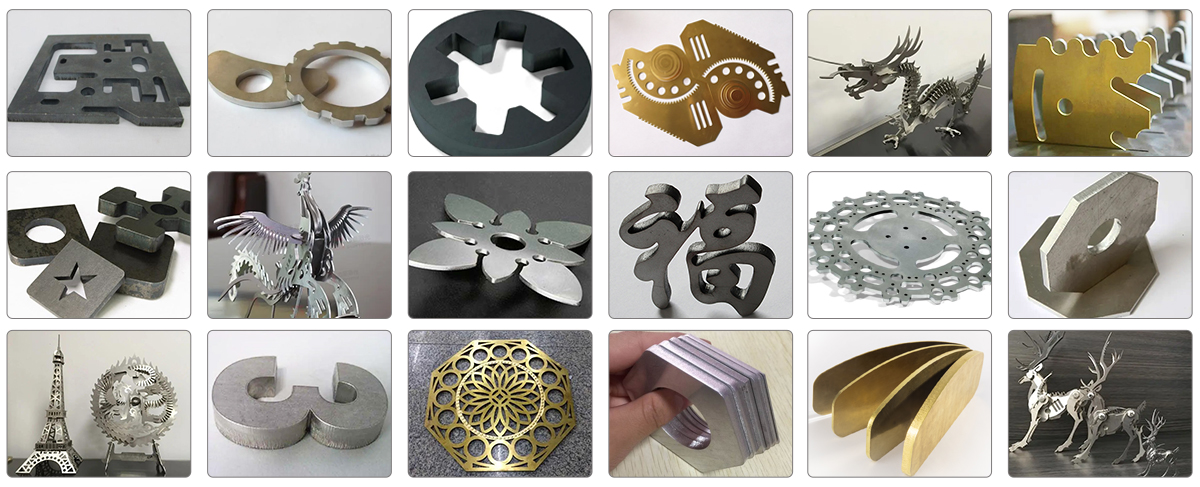

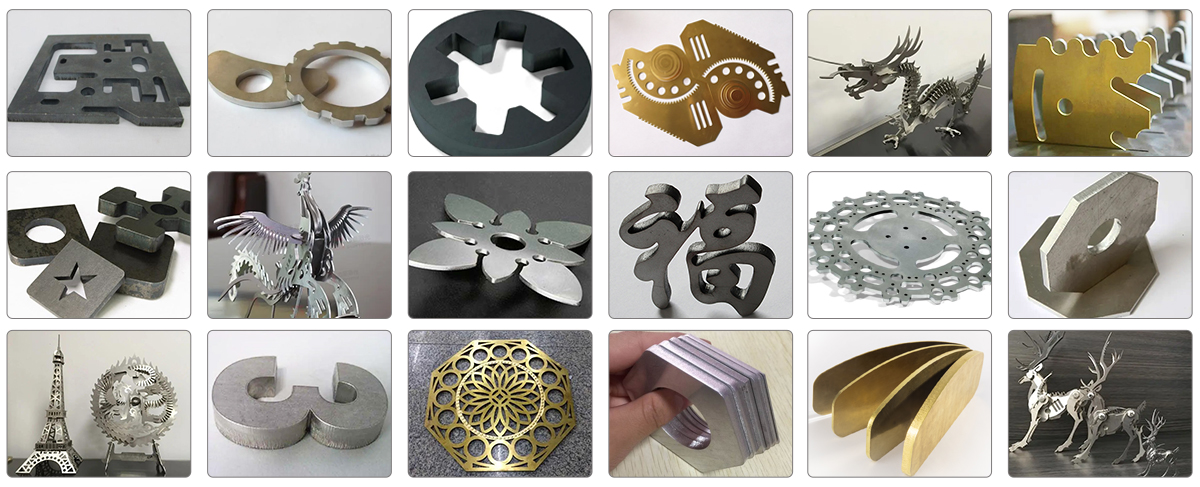

Laser cutting machine for metal application

Application materials

It can be used to cut various metal materials such as carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, galvanized sheet, etc.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of laser cutting machine for metal

Model | ST-FC3015G/ST-FC4020G/ST-FC1560G/ST-FC6020G/ST-FC6025G |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 1500*6000mm, 2000*6000mm, 2500*6000mm) |

Laser power | 1000W-20KW |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Laser wave length | 1064nm |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Maximum speed | 120m/min |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Equipment power | 8KW(not include laser generator and chiller) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc) |

Machine weight | 7500KG |

Machine dimension (L*W*H) | 8850*3210*2100mm |