Details Product Parameters Samples Video

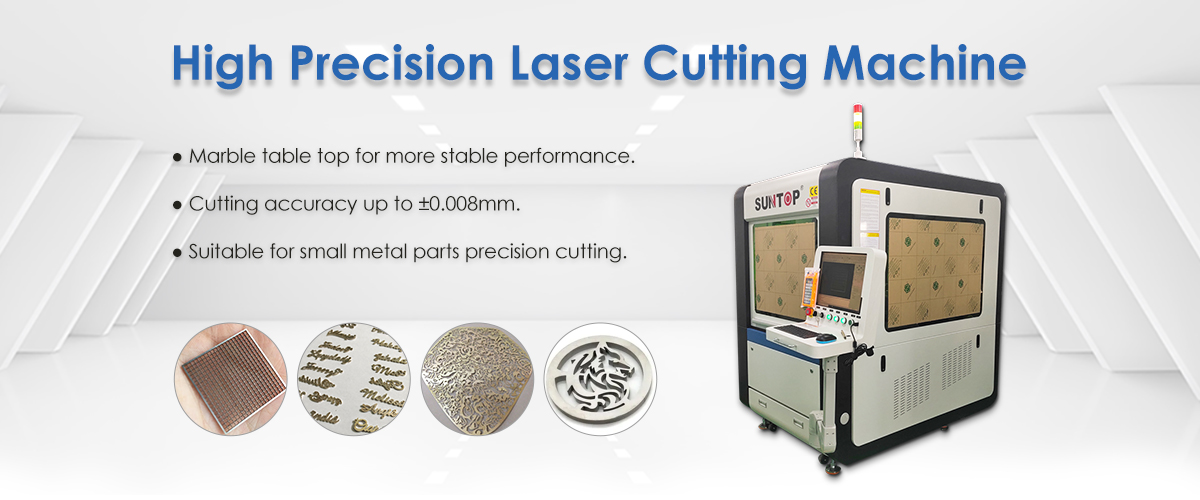

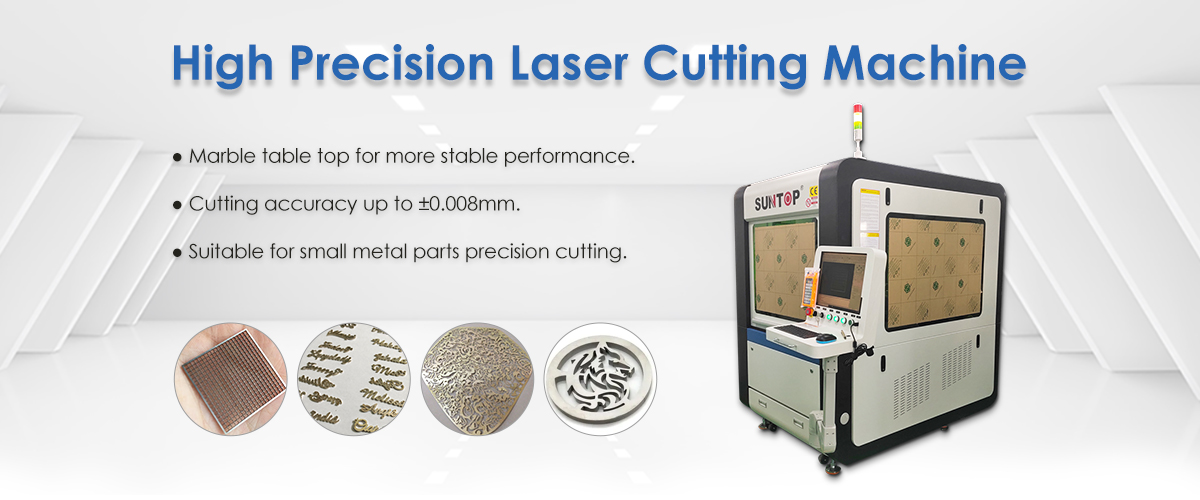

Features of fiber laser cutter

● Fully enclosed design, with laser protection function, in line with European CE standards.

● Imported servo motors and precision guide rails ensure high cutting precision, stability and longer life.

● High precision, more suitable for precision parts processing and cutting of various fine handicrafts.

● High performance, fiber laser with original imported packaging, stable performance and lifespan of more than 100,000 hours.

● Fast cutting speed, high work efficiency and high stability.

● The kerf is small, the deformation is small, the cutting surface is smooth, flat and beautiful, and there is no need for post-processing.

● Special software can design or process graphics or text in real time. Flexible and easy to operate.

Details of laser cutting machine for metal

1. Fiber laser source

The service life of 100,000 hours is more stable and the cost performance is higher. Raycus, IPG, MAX and other lasers are optional.

2. Auto focus laser cutting head

The focus will be automatically adjusted during the cutting process, which can achieve better cutting effects for metal pipes of different thicknesses.

3. Electric vertical lift door

One-button electric vertical lift door opening method, the visible protective door occupies zero area, which greatly reduces the occupied area, effectively improves the space utilization rate and better guarantees the safety of personnel.

4. Imported servo motor

High precision, high speed, high stability. Strong timeliness, short dynamic response time, less heat generation and low noise.

5. The third generation aviation aluminum beam

The gantry is manufactured according to aerospace standards, with an extrusion capacity of 4,300 tons. After aging treatment, its hardness can reach 6061 T6, which is the highest strength among all girders. Aviation aluminum has many advantages such as good toughness, light weight, corrosion resistance, oxidation resistance, and low density, and the processing speed is greatly improved.

6. Environmentally friendly and pollution-free

It meets the CE certification standard, fully enclosed design and optical fiber wavelength protective glass to achieve zero damage to human eyes, and the powerful dust removal system has zero-level pollution to the environment.

Advantages of laser cutting machine for metal

1. Use the famous Swiss brand Raytools laser cutting head, equipped with a dynamic automatic focusing system, it can keep the same distance between the metal sheet and the laser head to achieve the precision of the cutting effect.

2. The famous Japanese servo motor cooperates with the double ball screw drive system, and the cutting precision is higher than that of the single drive system.

3. Using the world-renowned fiber laser Raycus, the cutting speed can reach 15M/min.

4. Equipped with NC Studio control system, which can meet various cutting needs.

5. With red light indicator and pre-run function to ensure that the fiber laser cutting machine can find the exact cutting position.

6. With automatic oil filling function, each magnetic strip has an oil pipe, push the oil filling switch to automatically lubricate, and oil filling every two months.

7. The design of the protective cover is environmentally friendly and beautiful. Green glass cover window filters the laser beam and is harmless to the eyes.

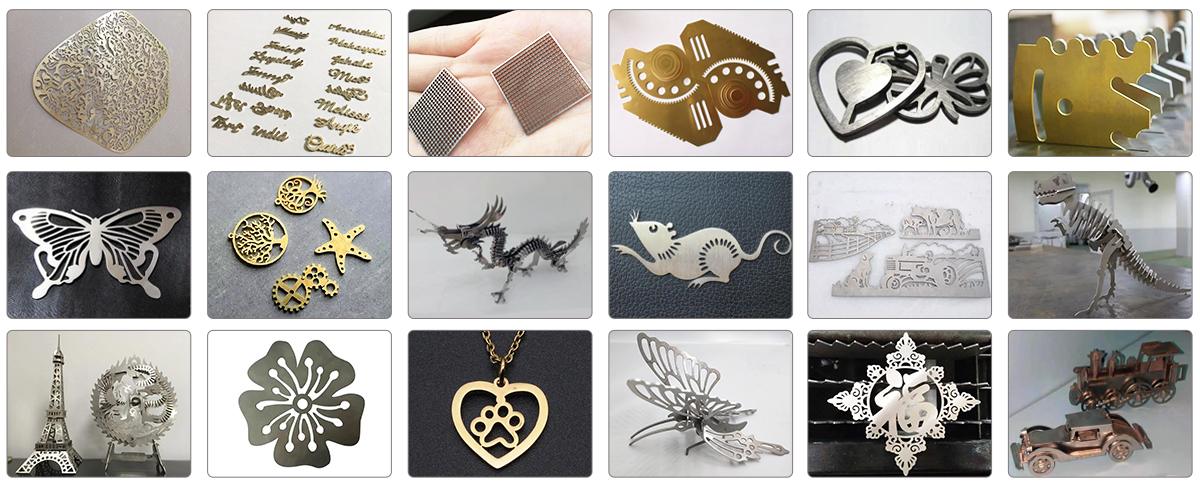

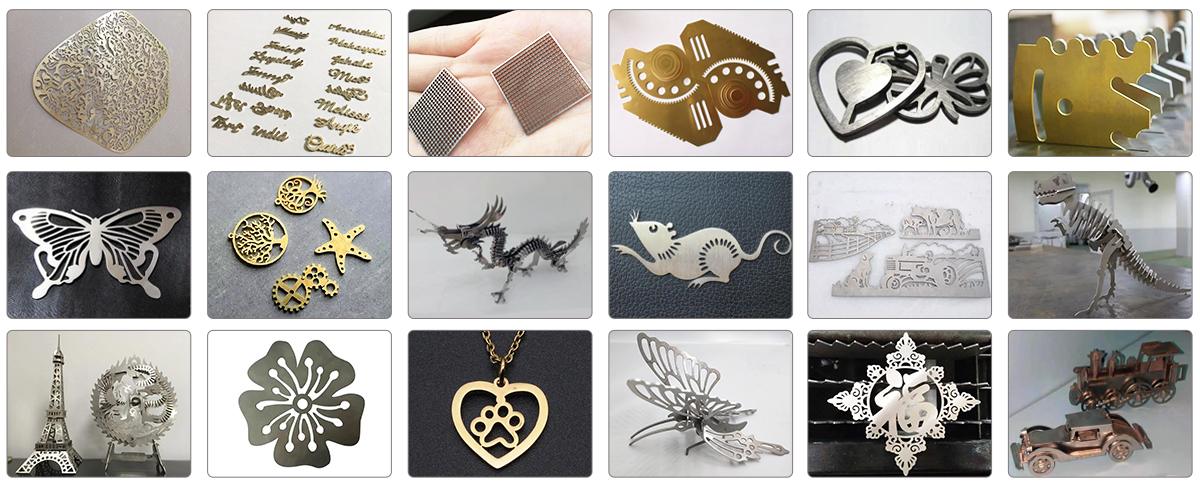

Laser cutting machine for metal application

Application materials

Suitable for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, aluminium zinc plate, pickled plate, copper, silver, gold, titanium and other metal materials.

Application industry

High precision apparatuses, aluminum copper clad laminates, machinery, electrical apparatuses, metal crate and cabinet, electric appliance shell, metal plate processing, sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Parameters of fiber laser cutter

Model | ST-FC6060/ST-FC6040/ST-FC1390 |

Table Max. cutting size | 600*600mm/600*400mm/1300*900mm |

Laser power | 1000W, 1500W, 2000W, 3000W, 4000W |

Cutting thickness | 0.5-20mm (depend on the actual laser power) |

Repeat positioning accuracy | ±0.01mm/m |

Maximum operating speed | 40m/min |

Laser type | Fiber Laser |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Laser wavelength | 1064nm |

Transmission | High precision screw guide transmission |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc.) |

Machine weight | 1300KG (depending on actual model) |

Machine dimension (L*W*H) | 1650*1360*1880mm (depending on actual model) |