Details Product Parameters Samples Video

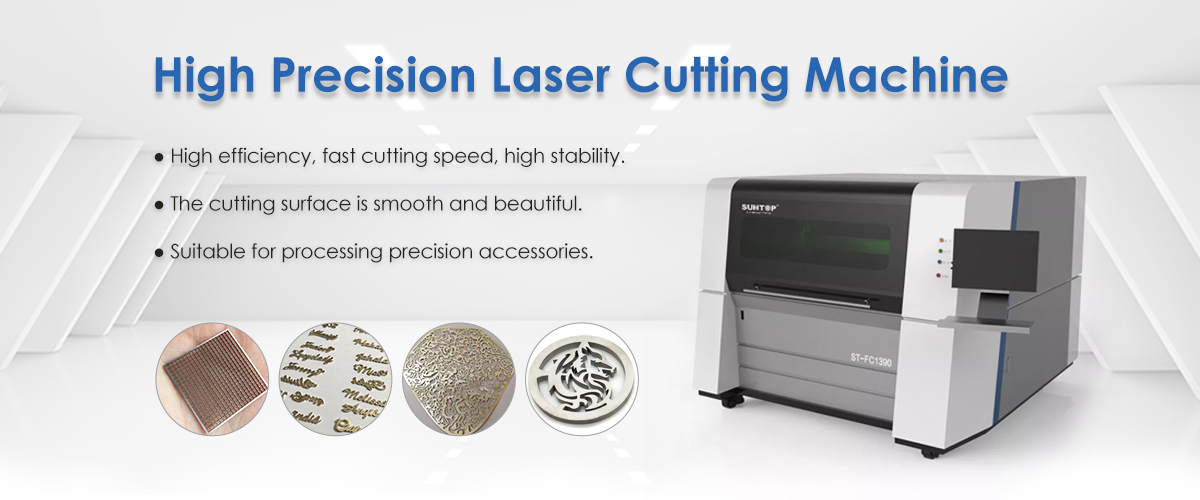

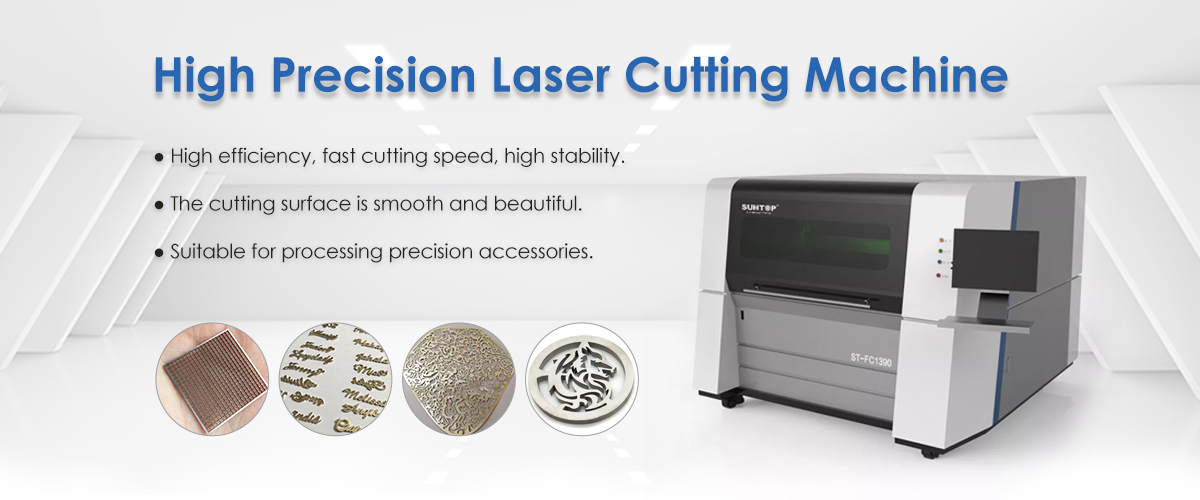

Features of precision metal laser cutting machine

1. Adopt imported servo motor and precision guide rail, high cutting precision, stable and long life.

2. Professional control software, flexible work, simple and convenient operation.

3. Imported laser generator with stable power, strong continuous working ability and long service life (no problem for 100,000 hours).

4. Fast cutting speed, high work efficiency and high stability.

5. The cutting seam is small, the deformation is small, the cutting surface is smooth, flat and beautiful, and there is no need for post-processing.

6. High precision, more suitable for precision parts processing and cutting of various fine handicrafts.

Details of precision metal laser cutting machine

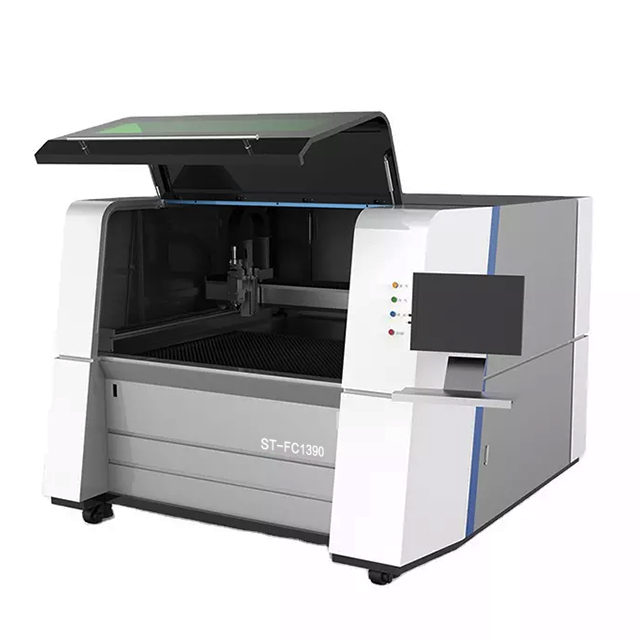

1. Adopt gantry double servo drive structure, high inertia servo motor, the maximum acceleration is 0.5G.

2. Adopt marble precision platform, high hardness, wear resistance, anti-magnetic, etc., to ensure the stability of precision when the bed runs at high speed, and ensure excellent workpiece quality.

3. Reinforced welded bed, high-rigidity beam, and high-precision marble platform effectively ensure a high-dynamic-rigidity machine tool system without deformation for a long time.

4. Imported lasers and optical devices, good spot quality, stable output power, and low maintenance costs.

5. Self-developed laser cutting software integrates excellent motion control performance and powerful graphics processing functions.

6. Adopt uniquely designed special smoke exhaust system, strong smoke and effective control of cutting effect.

Advantages of precision metal laser cutting machine

1. The cutting precision is high, the positioning precision of the laser cutting machine is 0.05mm, and the repeat positioning precision is 0.03mm.

2. Small heat-affected zone, not easy to deform. The slit is narrow, the cutting surface is smooth and burr-free, and no post-processing is required.

3. No damage to the workpiece, the laser cutting head will not touch the surface of the material, so as not to scratch the workpiece.

4. Energy saving and environmental protection, the photoelectric conversion rate can reach more than 30%, and the power consumption is low.

5. Low production cost, no mold, no tool wear, less material waste, and low labor cost.

Precision metal laser cutting machine application

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating, zinc plate, metallic copper, brass, silver, gold and other kinds of metals.

Application industry

Widely used in precision electronics, auto parts, high-precision instruments, precision machinery, aviation, aerospace, ships, metallurgical equipment, elevators, household appliances, gift crafts, tool processing, decoration, molds, advertising, mobile phone digital, sheet metal processing, Hardware products and other industries.

Parameters of precision metal laser cutting machine

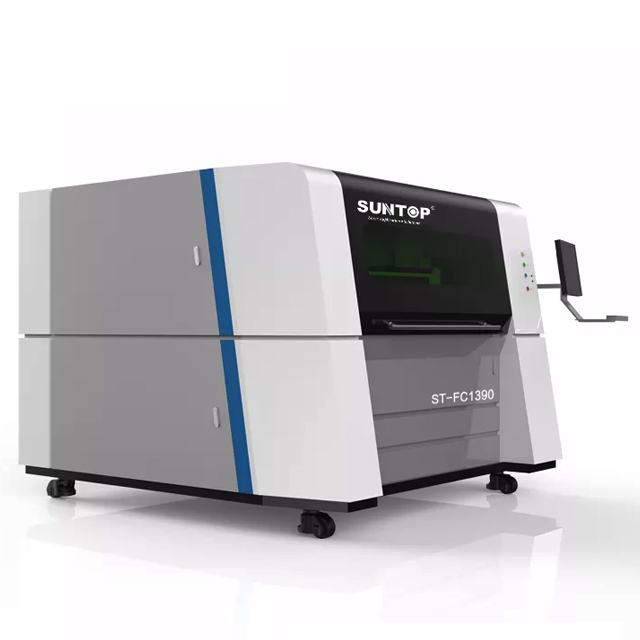

Model | ST-FC6060/ST-FC6040/ST-FC1390 |

Table Max. cutting size | 600*600mm/600*400mm/1300*900mm |

Laser power | 1000W, 1500W, 2000W, 3000W, 4000W |

Cutting thickness | 0.5-20mm (depend on the actual laser power) |

Repeat positioning accuracy | ±0.01mm/m |

Maximum operating speed | 40m/min |

Laser type | Fiber Laser |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Laser wavelength | 1064nm |

Transmission | High precision screw guide transmission |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc.) |

Machine weight | 1300KG (depending on actual model) |

Machine dimension (L*W*H) | 1650*1360*1880mm (depending on actual model) |