Details Product Parameters Samples Video

Features of jewelry laser cut machine

1. Integrated design, compact and reliable structure, safe, practical and reasonable.

2. High precision, more suitable for the processing of precision parts and cutting of various exquisite handicrafts.

3. Adopt imported servo motor or linear motor, high-precision grinding screw and CNC numerical control system, with fast speed, high precision and low maintenance rate.

4. Special software can design or process graphics or text in real time. Flexible and convenient operation.

5. The optical path of the whole machine is conducted by optica

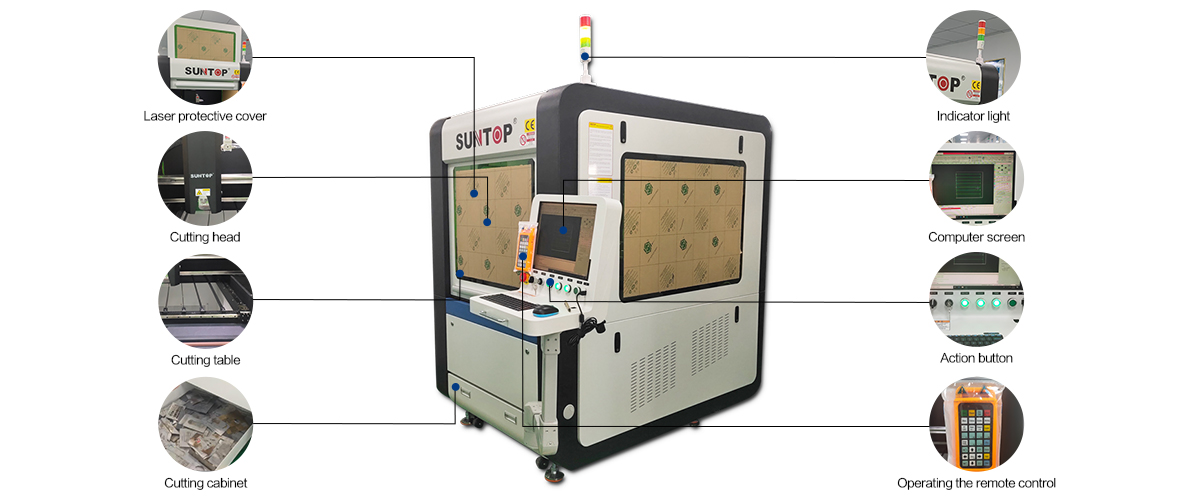

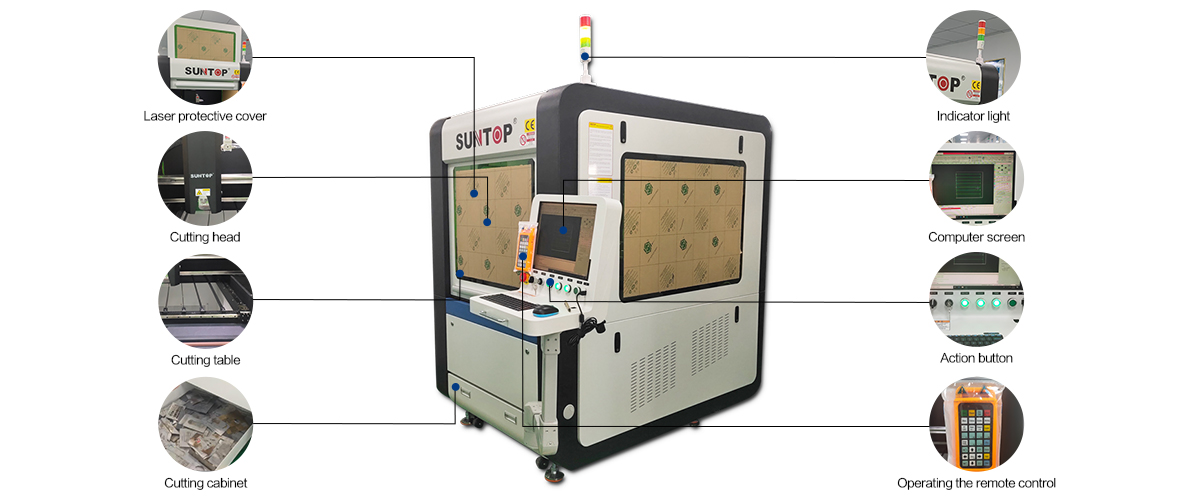

Details of jewelry laser cut machine

1. Adopt the famous brand RAYCU fiber laser, the most cost-effective, the best quality, and the best after-sales service (Suntop use the new and original laser).

2. Imported fiber laser cutting head is used, with dynamic auto-focus function, and the same distance can be kept between the metal plate and the cutting head when cutting.

3. Cutting protective window, the green glass cover window can filter the laser beam, does not hurt the eyes, has no peculiar smell, and is environmentally friendly and beautiful.

4. This machine adopts marble precision platform, gantry double-drive integrated closed structure, which has good rigidity, shock resistance and high-speed stability.

5. Double guide rail and double drive design are adopted. In order to prevent the deformation of the cutting line caused by the bending of the Y-axis screw, both sides of the Y-axis are equipped with double-rail guide rails and double-ball drive screw design to ensure straightness and radian during high-speed cutting.

6. Imported servo motor is adopted, and the extremely precise positioning makes the mobile positioning mechanism run smoothly. Reliable and maintenance-free.

Advantages of jewelry laser cut machine

1. High processing efficiency, fast cutting speed, short product production cycle, rapid prototyping cutting.

2. Good cutting quality, narrow kerf, smooth and beautiful cutting surface, no slag, no burr.

3. High cutting precision, the cutting precision is ±0.01mm. It is suitable for the cutting of precision accessories and the fine cutting of various craft words and paintings.

4. Low production cost, no need for molds, no tool wear, less material waste, and lower labor costs.

5. Energy saving and environmental protection, the photoelectric conversion rate can reach more than 30%. Low power consumption, about 20%~30% of traditional co2 laser cutting machine.

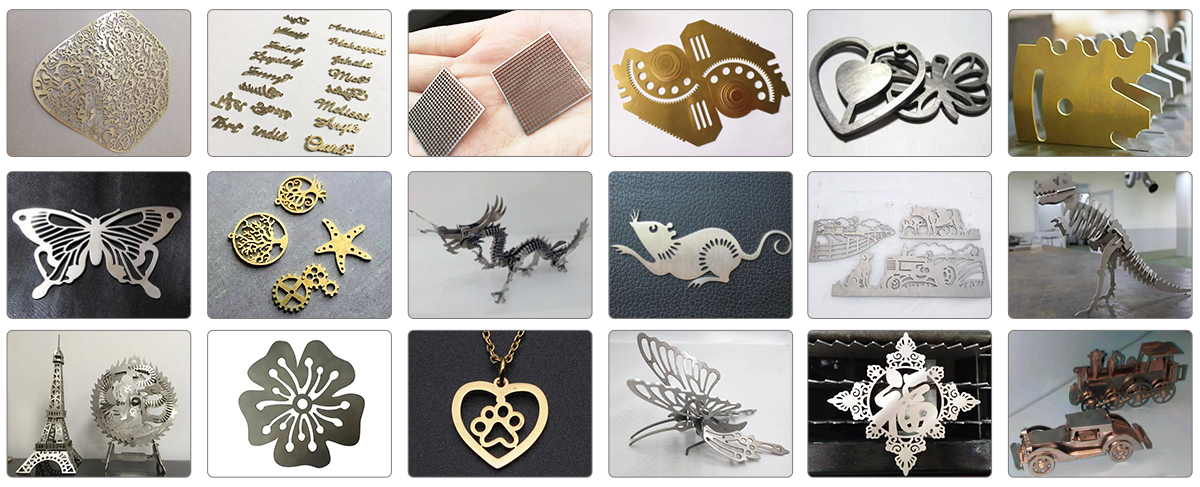

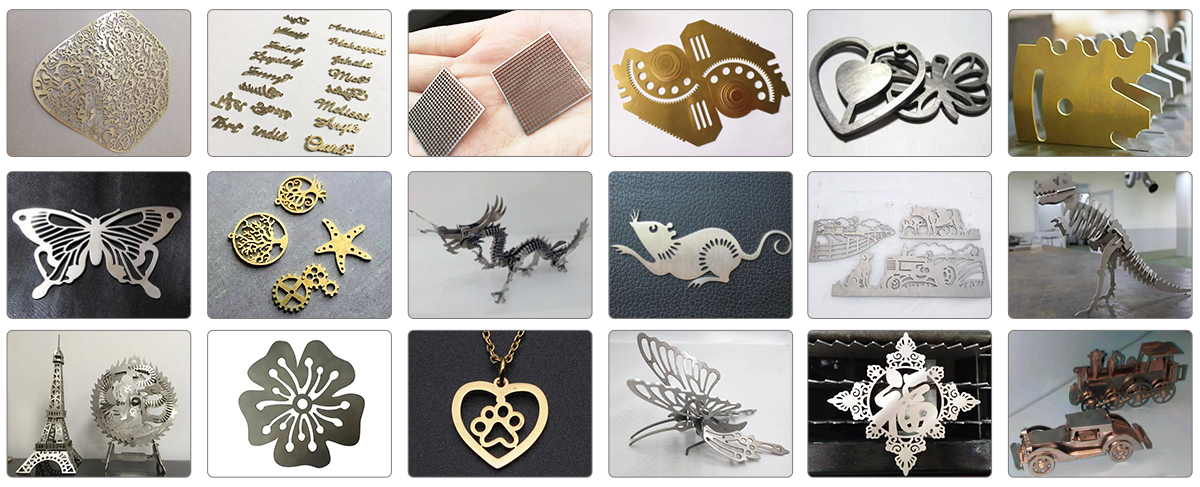

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating, zinc plate, metallic copper, brass, silver, gold and other kinds of metals.

Application industry

Applicable to gold jewelry, gold and silver jewelry, high-precision instruments, auto parts, hardware products, precision machinery, sheet metal industry, metal cabinets, aviation, aerospace, ships, metallurgical equipment, elevators, household appliances, gift crafts, tool processing , decorations, advertisements, metal external processing and other manufacturing and processing industries.

Parameters of jewelry laser cut machine

Model | ST-FC6060/ST-FC6040/ST-FC1390 |

Table Max. cutting size | 600*600mm/600*400mm/1300*900mm |

Laser power | 1000W, 1500W, 2000W, 3000W, 4000W |

Cutting thickness | 0.5-20mm (depend on the actual laser power) |

Repeat positioning accuracy | ±0.01mm/m |

Maximum operating speed | 40m/min |

Laser type | Fiber Laser |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Laser wavelength | 1064nm |

Transmission | High precision screw guide transmission |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc.) |

Machine weight | 1300KG (depending on actual model) |

Machine dimension (L*W*H) | 1650*1360*1880mm (depending on actual model) |