Details Product Parameters Samples Video

Features of ss laser cutting machine

1. The machine adopts fully automatic sheet metal loading and unloading system, which can save labour and greatly improve cutting efficiency and productivity, it can load single plate sheet metal with weight up to 2000KG.

2. The bed adopts a gantry dual-drive structure, imported screw rods and linear guide rails, stable transmission, high precision, and online rotation of the hobbing, which ensures high efficiency, high quality, time and labor saving of material processing , Improve material utilization.

3. Hobbing type conveying structure, vacuum chuck automatic unloading the unloading the finished product, saving labor and improving efficiency.

4. Suntop CNC fiber laser cutting machine mechanical transmission part has been tested and calibrated with USA brand laser interference for many times to ensure the our machine good and stable accuracy even after a few years of using.

5. Modular design, can be customized according to the special needs of the customer.

Details of ss laser cutting machine

1. Cast aluminum beam

Manufactured by aerospace standards, the beam has high density, high rigidity, and light weight, which can obtain higher dynamic response and improve processing efficiency.

2. Machine tools

A high-power machine tool with a hollow structure is welded with thick steel plates, and the weight of a single machine tool reaches 4 tons. Effectively reduce the heated area during laser cutting. Long-term use of the machine tool will not deform, but also ensure good cutting accuracy, greatly improving the stability of the machine. It will not be deformed after at least 20 years of use.

3. Auto focus laser head

Automatic control of various focal lengths, the focus will be automatically adjusted during the cutting process to achieve better cutting effects for metal pipes of different thicknesses.

4. Rack and pinion

Imported high-precision helical rack and pinion with high precision, high load, high reliability, and long-term stable operation.

5. Automatic lubrication system

The automatic lubrication system provides lubricating oil regularly and quantitatively for the equipment to ensure the high-speed operation of the equipment, and has abnormal alarm and liquid level alarm functions. This system greatly improves the cutting precision and effectively prolongs the service life of the transmission mechanism.

6. Intelligent alarm system

Intelligent travel protection, automatic monitoring of the working range of components, installation of international machine tool standard limit springs, built-in capacitor height adjustment function of laser cutting head, anti-collision stop, improve equipment safety performance and life safety protection, reduce accidents, and improve cutting efficiency.

Advantages of ss laser cutting machine

1. Realize automatic loading of raw materials, reduce the work intensity of operators, and save labor costs

2. Equipped with an intelligent detection system to prevent multiple sheets from being loaded at the same time during operation.

3. High material utilization rate, one-key processing of any piece of material, programming to form the best nesting method, realizing cutting of mesh material, and improving plate utilization rate.

4. The running range of beams and cutting parts can be monitored throughout the whole process, and the stop cycle can be quickly fed back, double protection, fixed position, greatly improving equipment and personal safety, and reducing customer use risks.

5. The cutting precision is high, the speed is fast, the cutting kerf is narrow, the cutting surface is smooth and burr-free, which improves the product quality.

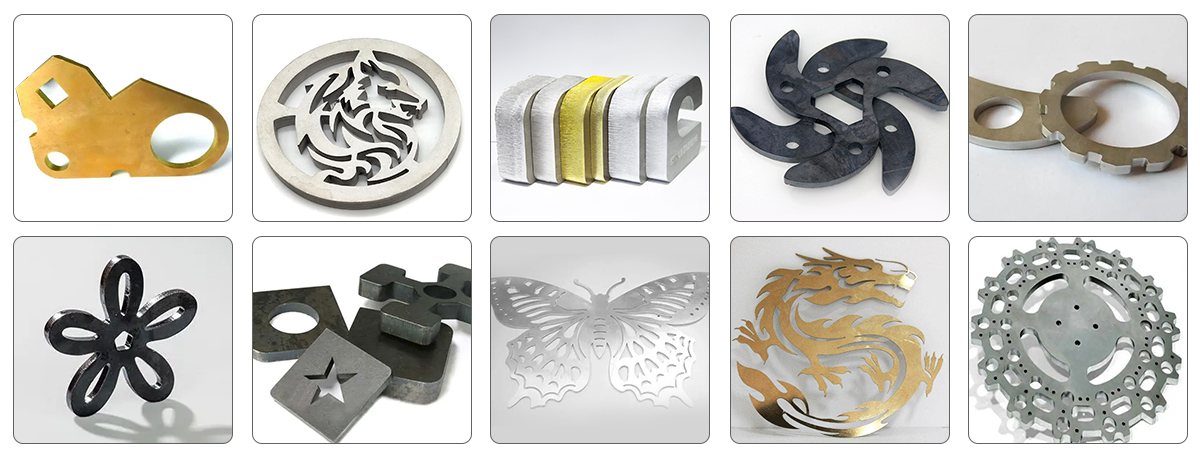

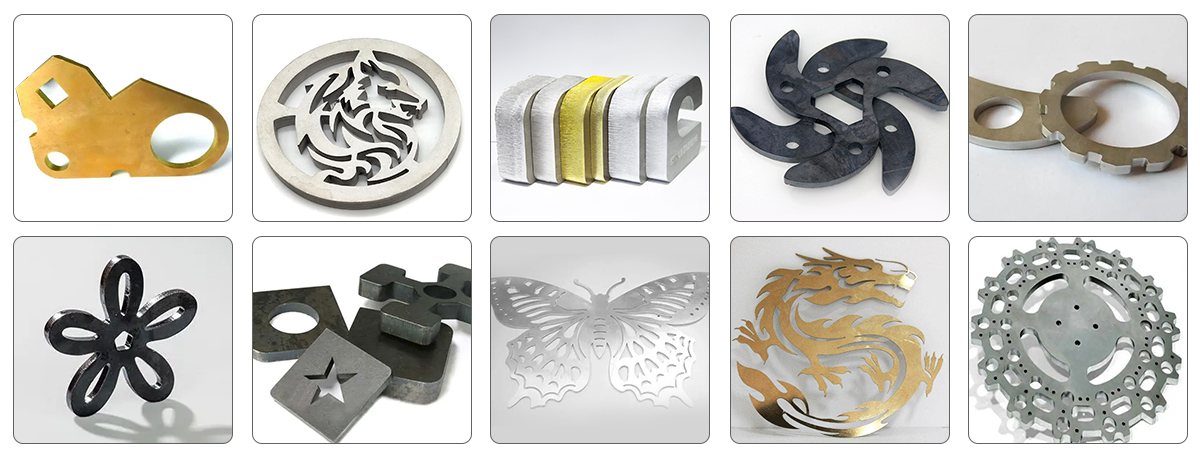

ss laser cutting machine application

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, alumina-plating, zinc plate, metallic copper, brass and other kinds of metals.

Application industry

Widely used in metal processing industries such as sheet metal processing, auto parts, kitchen and bathroom hardware, electronics, smart home, medical equipment, lighting industry, electrical equipment, aerospace, engineering machinery, precision accessories, advertising decoration, etc.

Parameters of ss laser cutting machine

Model | ST-FC3015R/ST-FC6015R/ST-FC6020R/ST-FC4020R |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (6000*1500mm, 6000*2000mm, 4000*2000mm) |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Maximum speed | 120meter/min |

Transmission system | Double rack & pinion and servo drive |

Tubes cutting capacity (standard) | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters |

Chuck type | Manual type or pneumatic self-centering chuck |

Maximum acceleration | 1.5G |

Power consumption | 6KW (based on laser power 1KW) |

Power supply | Three phase 380V/50Hz or 60Hz |

Machine weight | 7250Kg |

Overall size | 5050*2480*1830mm (L*W*H) |