Product Parameters Samples Video

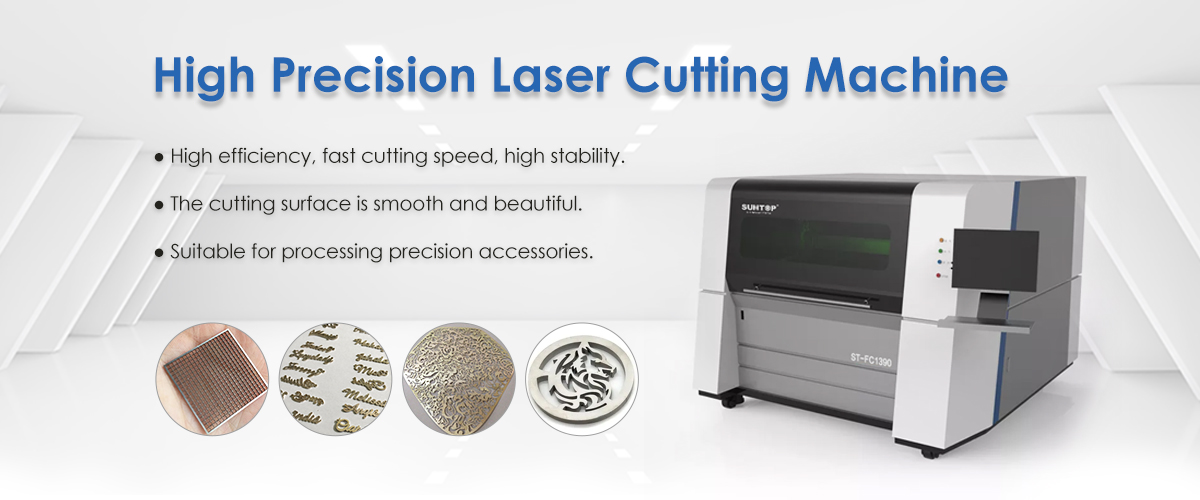

Features of small laser metal cutting machine

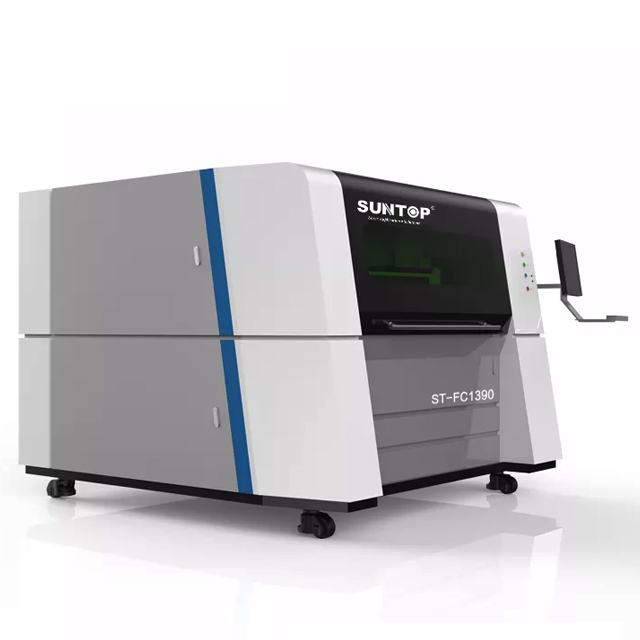

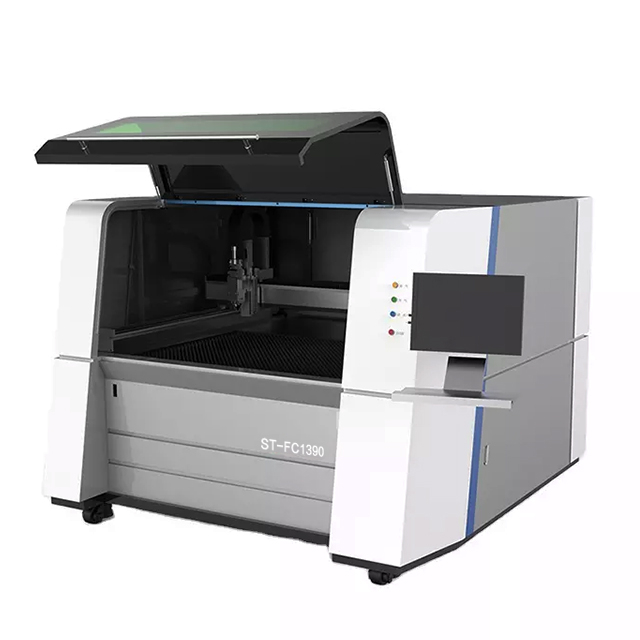

1. Fully enclosed design, with laser protection function, in line with European CE standards.

2. Imported servo motors and precision guide rails ensure high cutting precision, stability and longer life.

3. High precision, more suitable for precision parts processing and cutting of various fine handicrafts.

4. Fast cutting speed, high work efficiency and high stability.

5. The kerf is small, the deformation is small, the cutting surface is smooth, flat and beautiful, and there is no need for post-processing.

6. Special software can design or process graphics or text in real time. Flexible and easy to operate.

Details of small laser metal cutting machine

1. Brand laser

Imported lasers are used, with stable performance, high precision, and a service life of up to 100,000 hours.

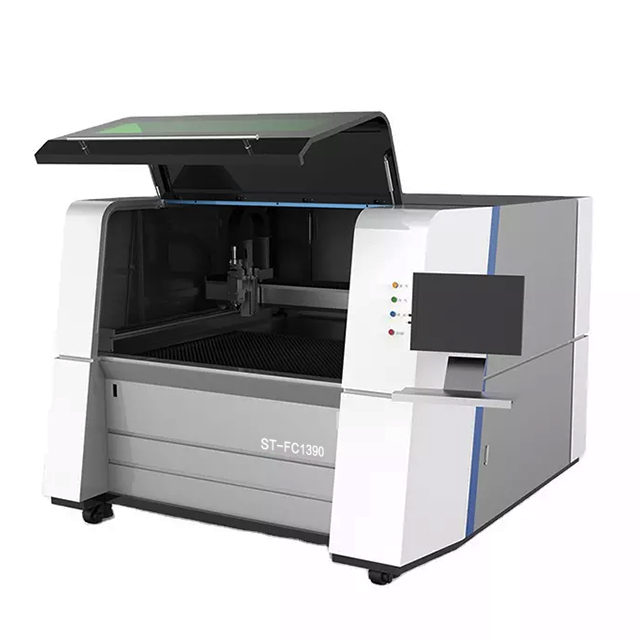

2. Auto focus laser cutting head

The focal length can be automatically adjusted according to the thickness of the material, and the cutting speed can be cut at a high speed.

3. Fast response to high-precision CNC and transmission system

It adopts marble base and gantry mobile platform structure machine tool, international famous brand linear motor or linear guide rail and precision screw drive, and bilateral servo motor synchronous drive to ensure stable transmission under high-speed cutting state and maintain excellent precision and speed. Greatly improve the long-term high-speed and stable operation of the bed.

4. Independent research and development of gas path control system

Capacitive sensors can easily realize functions such as height automatic tracking, active collision avoidance, segmented perforation, and automatic search. Fast speed, high precision, simple operation, greatly improving the quality of cutting and saving costs.

5. Integrated safety design

One-piece closed structure machine, the safety door filters the laser beam, does not hurt the eyes, prevents the debris from splashing on the human body during the cutting process, and protects the safety of the operator.

6. Professional cutting software

High-efficiency automatic typesetting function, automatic optimization of cutting path, reducing sheet waste generation. With a high-definition screen, the work is convenient and efficient.

Advantages of small laser metal cutting machine

1. It can guarantee the cutting process of small format, which is more suitable for some small pieces of metal materials.

2. The precision of the cutting machine is relatively high, and the focused light spot is relatively thin, the cutting precision can reach 0.1mm, and the cutting surface is also very flat and smooth.

3. The cutting speed is also very fast, more than 100 times that of wire cutting.

4. Small size, relatively low cost and low maintenance cost.

5. Save mold investment, save material, and save cost more effectively.

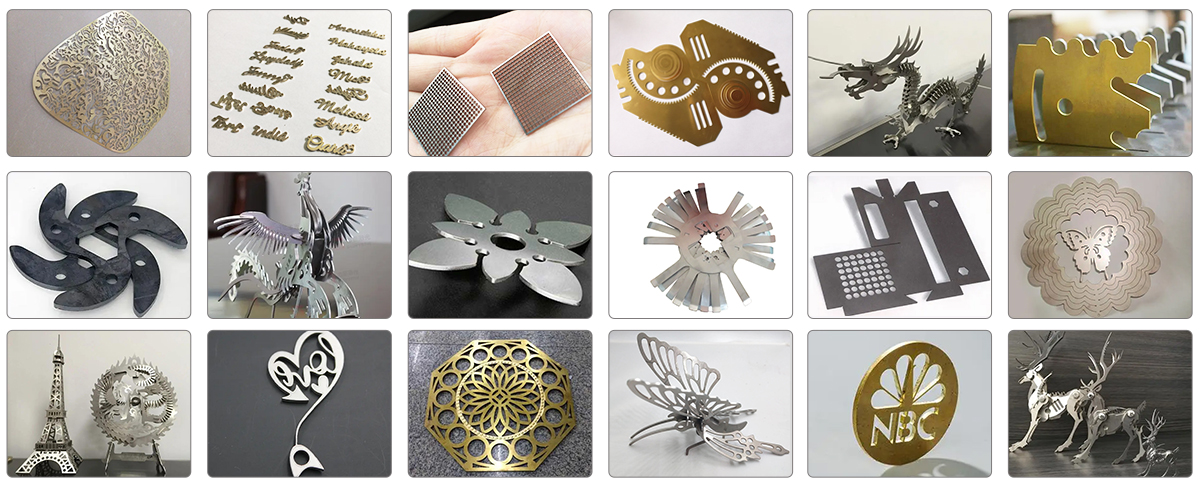

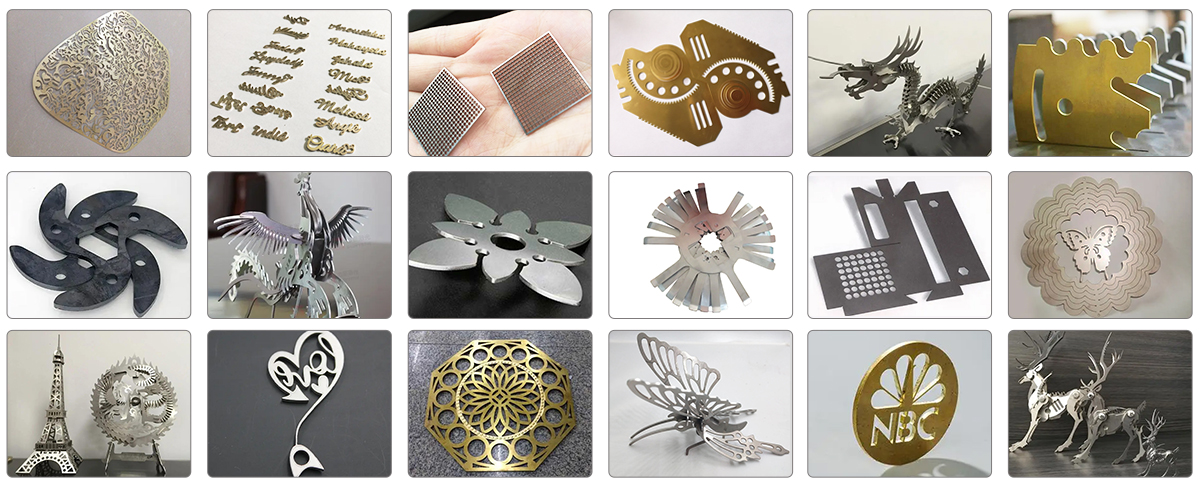

Small laser metal cutting machine application

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating, zinc plate, metallic copper, brass, silver, gold and other kinds of metals.

Application industry

Widely used in various manufacturing and processing industries such as sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, crafts and gifts, tool processing, decoration, advertising, and metal external processing.

Parameters of small laser metal cutting machine

Model | ST-FC6060/ST-FC6040/ST-FC1390 |

Table Max. cutting size | 600*600mm/600*400mm/1300*900mm |

Laser power | 1000W, 1500W, 2000W, 3000W, 4000W |

Cutting thickness | 0.5-20mm (depend on the actual laser power) |

Repeat positioning accuracy | ±0.01mm/m |

Maximum operating speed | 40m/min |

Laser type | Fiber Laser |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Laser wavelength | 1064nm |

Transmission | High precision screw guide transmission |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc.) |

Machine weight | 1300KG (depending on actual model) |

Machine dimension (L*W*H) | 1650*1360*1880mm (depending on actual model) |