Product Parameters Samples Video

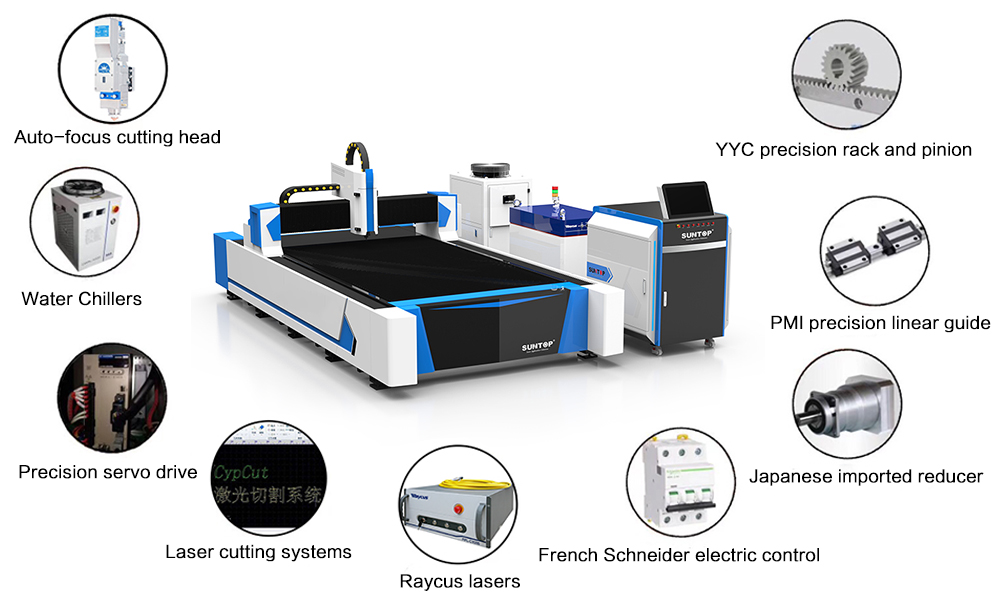

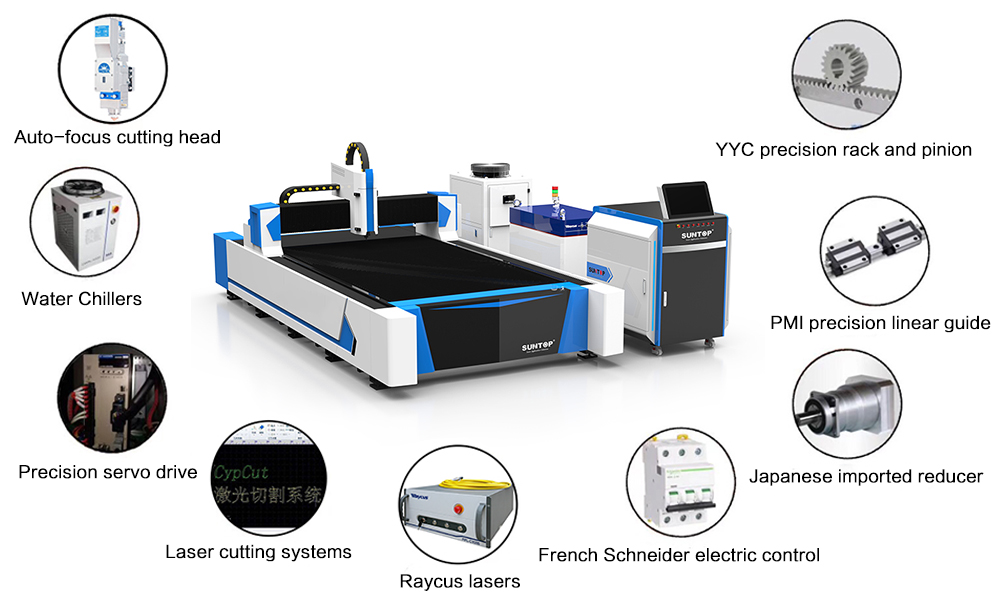

Single Table Fiber Laser Cutting Machine Machine main features

1, Machine frame, our machine tool is used integrated welding after annealing to eliminate stress, the process of cutting welding stress relief annealing—roughing—VSR—semi-finished-VSR-Finishing, a better solution due to welding and the stress arising from the processing, which greatly improve the stability of the machine, the common thickness range of structure metal profiles from 12-15mm which at least 20 years no deformation.

2, The mechanical transmission part has been tested and calibrated with laser interferometer for many times to ensure the our machine good and stable accuracy even after a few years of use, which is VERY important for end users.

3, Configure with HIWIN linear rail for all axis,to ensure durable and high precision for long time processing.

4, XY axis configure with high accuracy grinding type and rack,Japan Shimpo reducer,high speed and precision can be ensured,Z axis area are transmitting by high accuracy rolling ball screw.

5, Adopt France Schneider AC servo system,large power,stronger torque force,working speed is more stable and faster.

6, Adopt professional swiss Raytools laser cutting head,imported optical lens,focus spot smaller,cutting lines more precise,higher efficiency and better processing quality can ensured. Configure with non-contact auto follow function,ensure the best focal length and cutting effect.

7, Fiber laser transmitting with famous laser Generator, flexible processing,realized high accuracy cutting on every point.

8, Professional laser cutting CNC controlling system,connected with computer,simple operation and France Schneider AC servo system,large power,stronger torque force,working speed is more stable and faster.

9, Configure professional industrial HANLI or TEYU chiller with double temperature control molds,high cooling efficiency and high transferring ratio of laser. Japan SMC intelligent gas group,dual gas control,automatic adjustment for gas type and gas software.

10, Compatible with multiple software.can design and graphic and letters as you like,operating simple,flexible and easy.

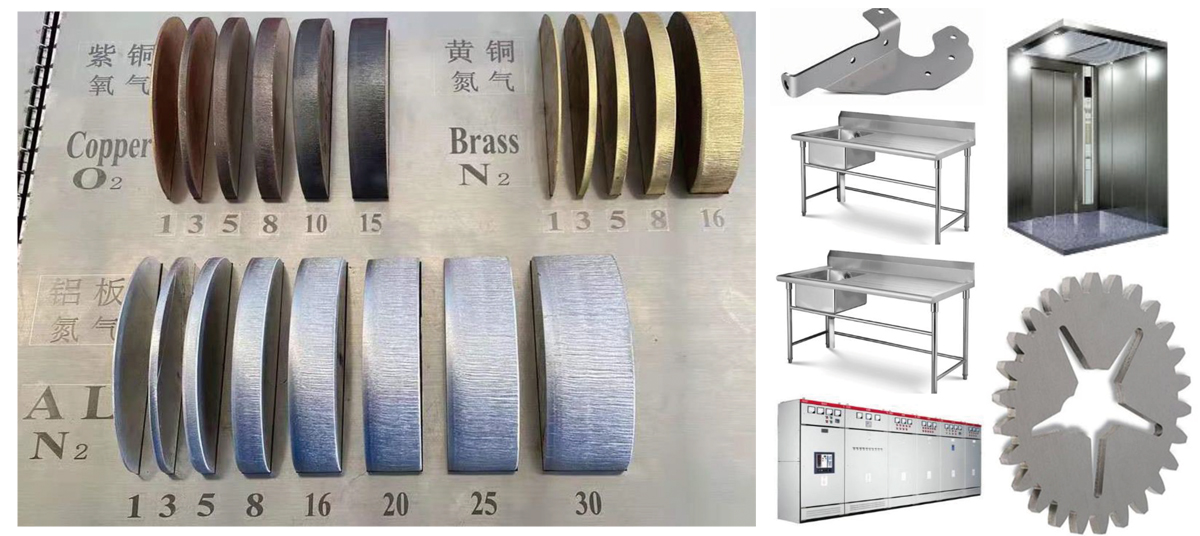

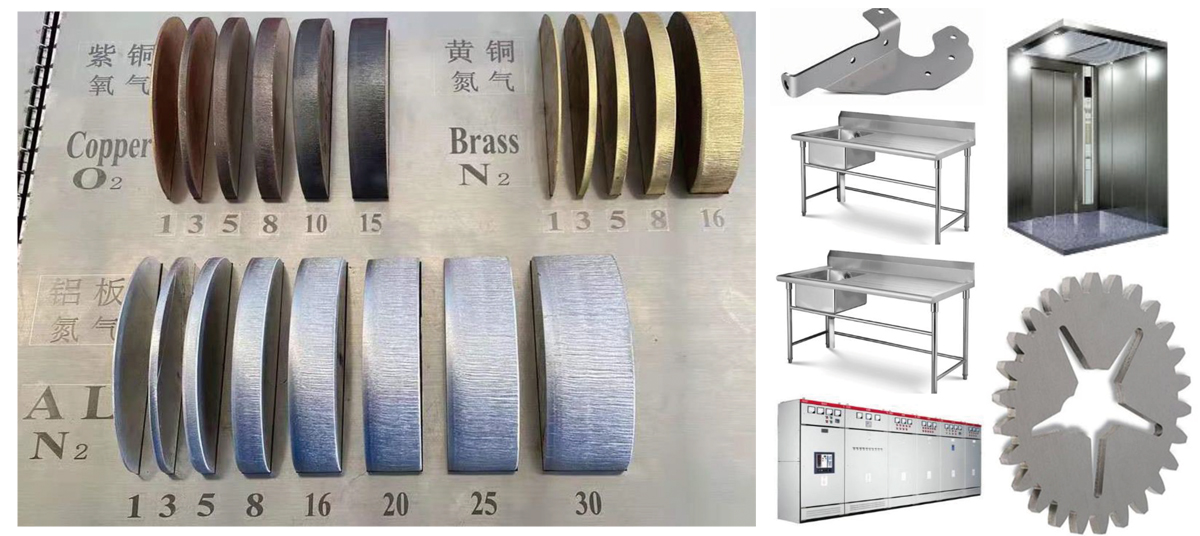

Single Table Fiber Laser Cutting Machine Machine Application materials

Steel metals processing, advertising sings production, high and low voltage electrical cabinet production, mechanical parts, kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, metal board, kettles, medical microelectronics, hardware, knife measuring tools and other metal processing industry.