Details Product Parameters Samples Video

Features of metal laser cutting machine

1. High-speed parallel exchange platform, double worktable exchange at the same time, stable and reliable transmission mode, shortened exchange time, good frequency converter.

2. High-speed, ultra-precision imported brand servo drive and servo motor, high environmental resistance performance, meet safety standards, and realize visual operation.

3. It has various flexible process settings such as automatic nesting, multi-level perforation, flying cutting, fast leapfrog, film removal process, starting and closing.

4. Equipped with a special laser numerical control system, the processing accuracy is guaranteed under high-speed operation conditions, the production efficiency is high, and the processing accuracy is high.

5. Famous brand Raycus, IPG, MAX fiber lasers, stable performance, service life can reach 100,000 hours, and the overall quality of the equipment is guaranteed.

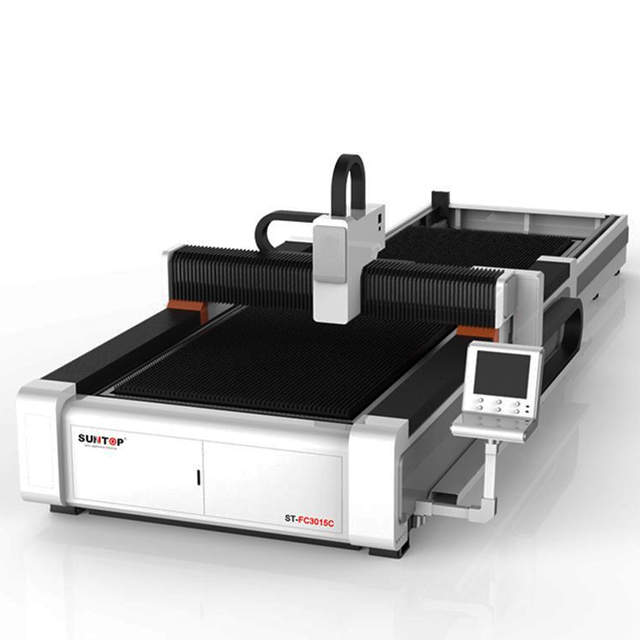

Details of metal laser cutting machine

1. Exchange platform

The rack and pinion transmission system has good rigidity and higher precision, which saves the waiting time for loading and unloading. Compared with the traditional sprocket and chain transmission mode, the load time is shorter and the efficiency is higher. The inverter controls the exchange motor, and the platform is replaced within 10 seconds.

2. Heavy machine tools

The whole machine adopts a thick carbon steel structure, and the weight of a single machine tool reaches 4 tons. The hollow structure of the high-power machine effectively reduces the heating area during laser cutting. The machine tool will not be deformed during long-term use, and at the same time it ensures good cutting accuracy and greatly improves the stability of the machine tool. It will not be deformed after at least 20 years of use.

3. The third generation aviation aluminum alloy gantry

Manufactured using aerospace standards, extruded by 4300 tons of pressure. After aging treatment, its strength can reach 6061T6, which is the highest strength among all gantry frames. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, oxidation resistance, low density, and greatly improved processing speed.

3. Laser cutting head

No need to manually manual focus, the software automatically adjusts the focus mirror. Control the up and down height to achieve automatic perforation and cutting of different thickness plates. Automatic adjustment of the focusing lens is ten times faster than manual adjustment.

4. Intelligent operating system

Professional intelligent control system with automatic nesting function, stable performance, fast operation, and supports multiple common file formats. One-click import of multiple types of cutting graphics and accurate cutting instructions make the user experience better.

Advantages of metal laser cutting machine

1. Independent high and low double worktable, fast exchange speed, saving loading and unloading time.

2. High precision, fast speed, narrow kerf, minimum heat-affected zone, smooth cutting surface without burrs.

3. Non-contact cutting, the cutting edge is slightly affected by heat, basically no thermal deformation of the workpiece, and no secondary processing is required.

4. Save costs, maximize the use of materials, and do not need molds.

5. Safety and environmental protection, less waste in laser processing, low noise, clean, safe, and pollution-free, greatly improving the working environment.

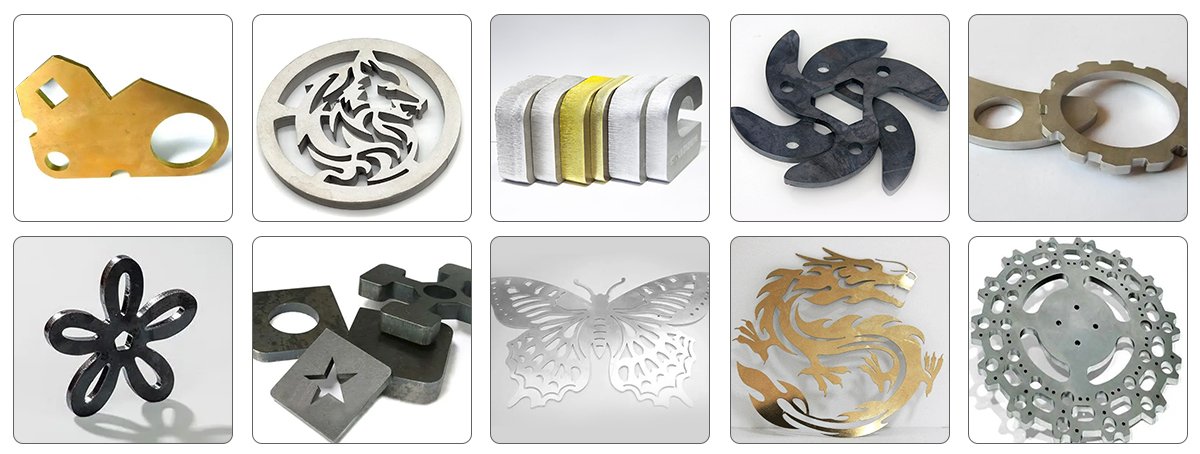

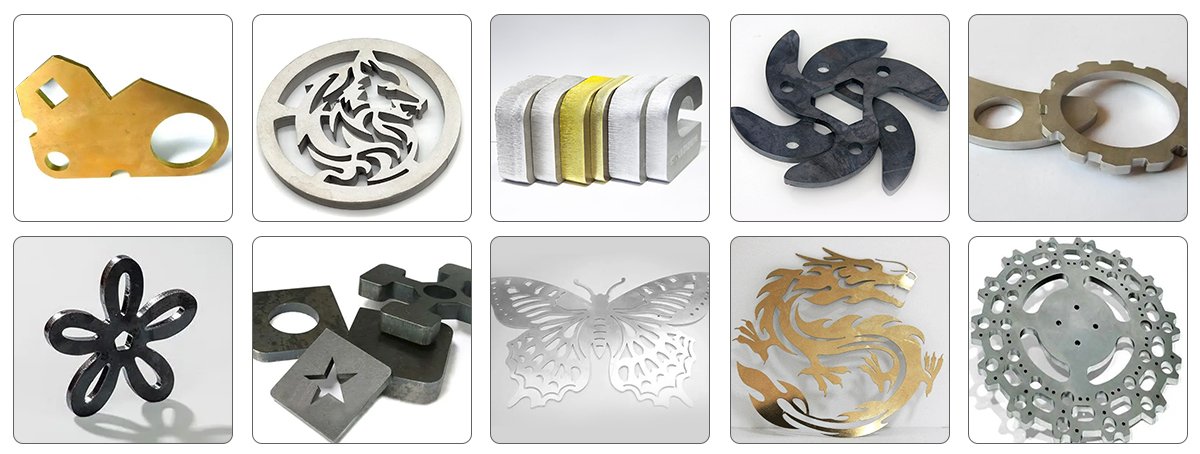

Metal laser cutting machine application

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, alumina-plating, zinc plate, metallic copper, brass and other kinds of metals.

Application industry

Widely used in sheet metal processing, round and square pipes, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobiles, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industries.

Parameters of metal laser cutting machine

Model | ST-FC3015C/ST-FC4020C/ST-FC6015C/ST-FC6020C |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 6000*1500mm, 6000*2000mm) |

Laser wavelength | 1064nm |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Maximum speed | 120m/min |

Repeat positioning accuracy | ±0.02mm |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Power consumption | <10KW |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | Three phase 380V/50Hz or 60Hz |

Machine weight | 5000KG |

Machine volume | 37m³ |