Details Product Parameters Samples Video

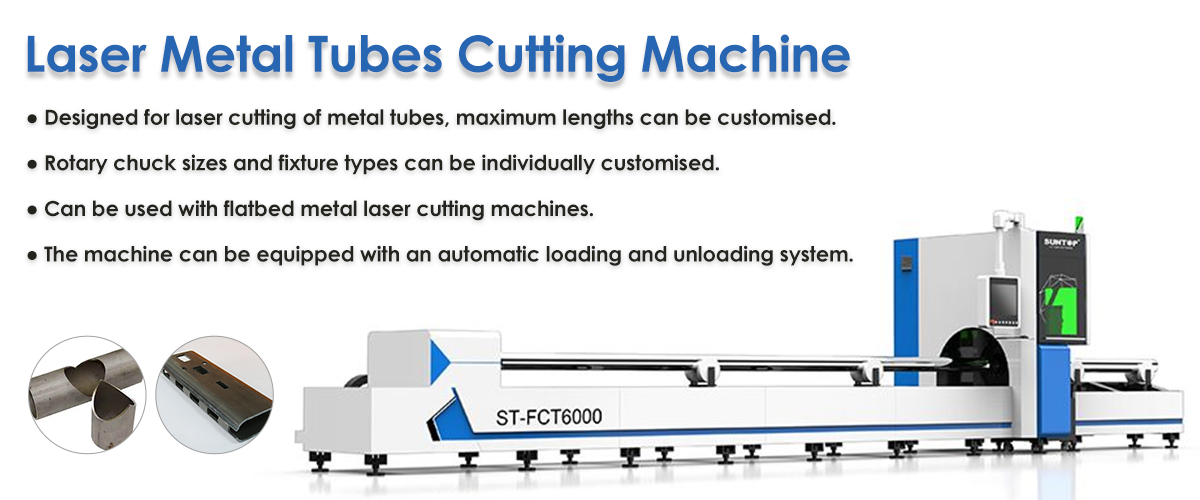

Features of laser tube cutter

1. Bochu CNC system adopts Windows operating system, a special platform for laser pipe cutting machine, and integrates a special module for laser cutting control, with powerful functions, good man-machine interface and simple operation.

2. Professional pipe cutting programming software realizes full-time cutting and high-efficiency cutting, effectively saves materials and improves cutting efficiency.

3. Capacitive fiber laser cutting head, high sensing precision, sensitive response, stable and reliable performance.

4. Unique hosting device, while the pipe is fed and rotated, the hosting device is always in contact with the surface of the pipe, and the supporting force is set according to the specification of the pipe to ensure effective support, prevent the pipe from sagging, reduce the axis swing when the pipe rotates, and improve Precision.

5. A complete library of cutting process parameters, and a user-friendly parameter interface, realizes the "one-key setting" processing process according to the type of pipe, and can also modify the laser cutting process parameters in real time in the interface.

6. The high-precision servo proportional valve precisely controls the air pressure of the cutting auxiliary gas and the clamping force of the chuck, and has achieved the best seven effects.

7. Optional automatic loading and unloading function can reduce the number of operators and improve processing efficiency.

Details of laser tube cutter

1. Fixture design

Both sides are designed with electric clips, which can be automatically adjusted. The adjustable range of diagonal is 20-200mm.

2. Fractional automatic support installation

The intelligent pipe support design is adopted to solve the deformation problem during the cutting process of long pipes.

3. The third generation aviation aluminum mast

Manufactured by aerospace standards and extruded by a 4,300-ton press. After aging treatment, its strength can reach 6061 T6, which is the highest strength of all gantry frames. Aviation aluminum has the advantages of good toughness, light weight, corrosion resistance, oxidation resistance, and low density, which greatly improves the processing speed.

4. Heavy-duty bed design

The high-power machine with hollow structure effectively reduces the heating area during laser cutting. It is made of welded steel plates, and the weight of a single machine is 4 tons. The machine will not be deformed during long-term use, which also ensures good cutting accuracy and greatly improves the stability of the machine. Use at least 20 years without deformation.

5. Dedicated laser cutting head

The special laser cutting head for pipes, together with the special cutting system and nesting software, can realize the long-term cutting function of various pipe fittings.

6. Easy to operate

The wireless controller is used to freely control the clamping pressure, the control operation is convenient, and the deformation of the pipe is reduced.

Advantages of laser tube cutter

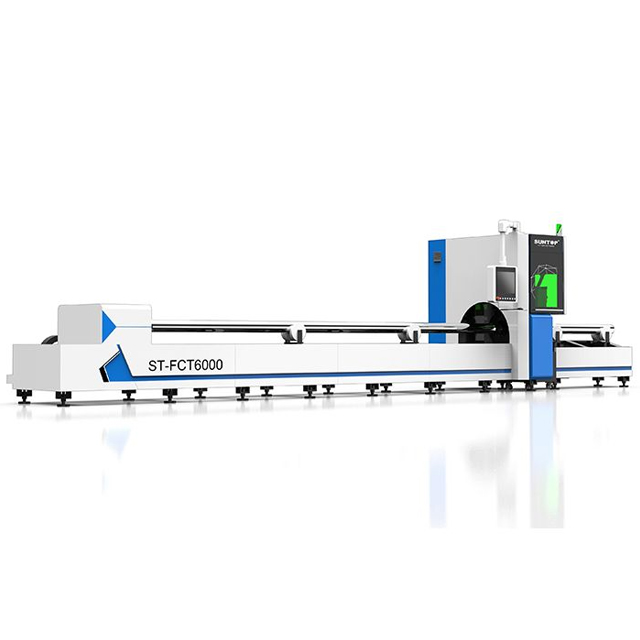

1. It adopts double chuck design mechanism, which has the functions of cutting, perforating, beveling and various irregular shapes of pipes such as round pipes, square pipes and oval pipes.

2. For the processing of slender tubes, an auxiliary support device with automatic avoidance is specially designed, which can effectively restrain the jumping of the tube caused by the high-speed rotation of the tube and improve the cutting accuracy.

3. The cutting speed is fast and the precision is high, and the pipe laser cutting machine can realize the precision cutting of opening, cutting, intersecting lines and various special-shaped complex graphics that are difficult to achieve by conventional methods.

4. Select a professional dedicated pipe cutting system, and support the bevel cutting function with a special nesting system to effectively meet the needs of various pipe cutting.

5. It can be equipped with automatic loading and unloading function. According to the size of the pipe, the feeding position of the mechanism can be automatically adjusted to ensure the orientation and separation of the pipe, and ensure that different pipes can be accurately sent to the center of the main machine chuck.

Laser tube cutter application

Application materials

Laser cutting, drilling, slotting, arc cutting, engraving, etc. can be performed on square tubes, round tubes, oval tubes, special-shaped tubes, angle steel, channel steel, H-shaped steel, etc. It is suitable for cutting stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickled steel, galvanized pipe, metal copper, brass and other rare metal pipes.

Application industry

Widely used in furniture industry, construction industry, kitchen and bathroom supplies, lighting equipment, automobile manufacturing, medical equipment, hardware processing, fitness equipment, mold laser cutting, aerospace, machinery, handicrafts, tool processing, decoration and other industries.

Parameters of laser tube cutter

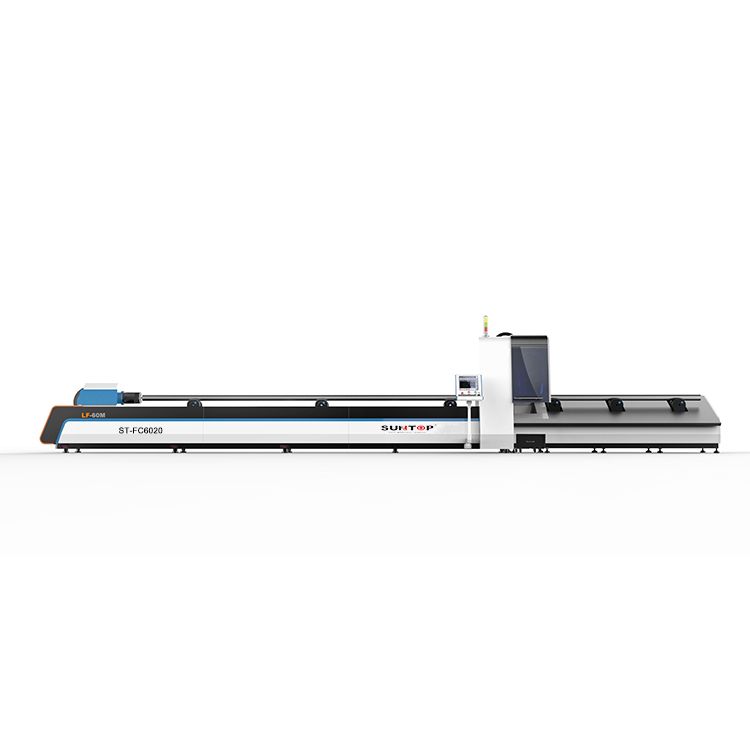

Model | ST-FCT6000/ST-FCT3000 |

Laser power | 1000W-20KW |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Tubes cutting capacity | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters (optional) |

Chuck type | Manual chuck type or pneumatic self-centering chuck (optional) |

Power consumption | 6KW (based on laser power 1KW) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 4850Kg |

Machine dimension | 12000*1650*2280mm (L*W*H) |