Details Product Parameters Samples Video

Features of laser cutting for metal for sale

● Enclosed design: The enclosed design reduces laser radiation and exhaust gas emission, improving safety and environmental protection.

● Exchangeable worktable: the equipment is equipped with an exchangeable worktable, which can realize automatic material change, fast loading and unloading, and improve production efficiency.

● High Precision: Using fiber laser with high beam quality and high stability, it can realize high precision cutting processing.

● High-quality machine: The use of high-power hollow structure machine effectively reduces the heating area during laser cutting. All of them are made of thick steel plates welded together, and the weight of only one machine is 4 tons. The stability of the machine is greatly improved, no deformation for at least 20 years.

● High degree of automation: with the automated worktable and automated control system, it can realize fully automated machining process and improve productivity.

● High efficiency: fiber laser cutting machine cutting speed, high efficiency, can achieve mass production, saving time and labor costs.

Details of laser cutting for metal for sale

1. Fiber laser source

Adopt famous brand Raycus, MAX, IPG and other fiber laser. Better and more stable beam quality, better anti-high reflection ability, high reliability and long life.

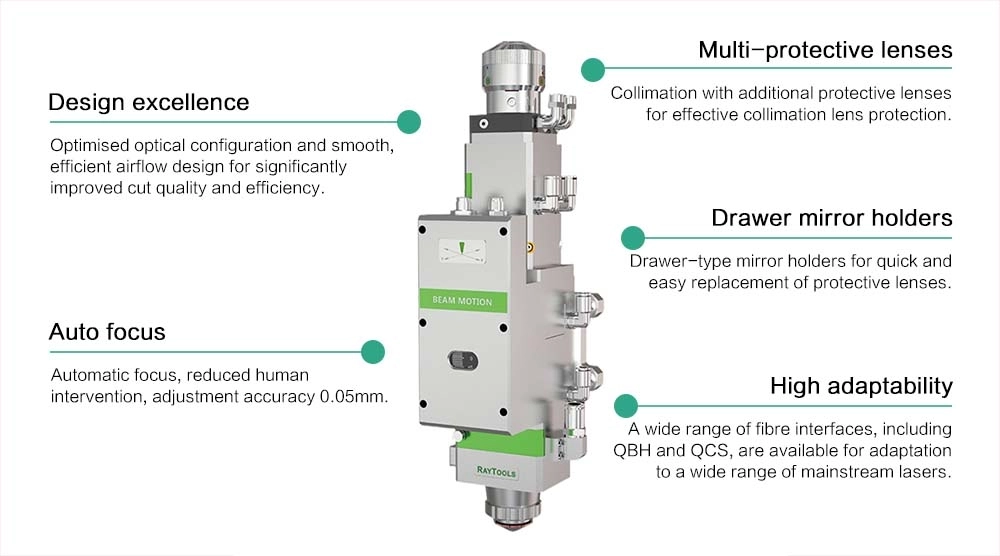

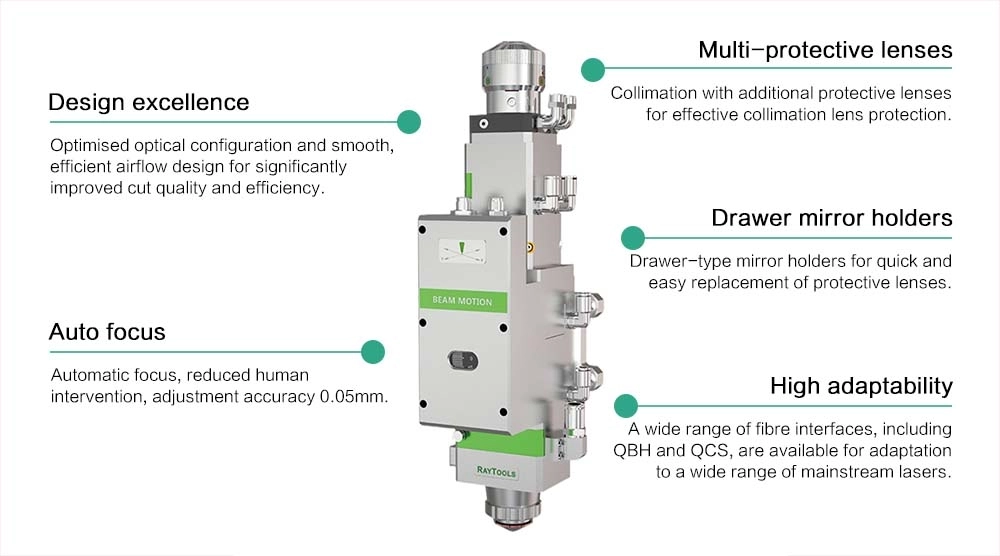

2. Raytools automatic adjustment of the laser head

Flexible focus adjustment, no need to manually focus, easy to operate. Control the vertical height, automatic focusing, fast completion of high-speed perforation of thick plates, automatic cutting of different thicknesses of materials.

3、Machine tool

The bed adopts integral welded structure, rough machining after annealing to eliminate internal stress, finishing after the second vibration aging treatment, which greatly improves the stability of the machine tool. The upper side of the main beam of the bed is covered with composite armor, which can effectively improve the influence of the high temperature generated during high-power laser cutting on the overall structure of the frame; there is a smoke vent under the bed, and the smoke is automatically discharged through the smoke pipe, which can make the smoke and dust generated in the process of cutting easily discharged outside and improve the working environment; the whole working area adopts a fully enclosed cover, which is reasonable in terms of safety and protection.

4. Crossbar

Adopting gantry beam design, light weight, good rigidity, good dynamic performance and smooth running. The fully enclosed dustproof structure greatly improves the service life of the built-in rack and pinion and linear guide. Anti-corrosion, anti-oxidation, good toughness, high elasticity.

5. Rack and pinion

Adopting grinding technology, adapting to all kinds of use conditions, dust-proof, ensuring long-term high-precision movement.

Advantages of laser engraver for metal for sale

● High-quality cutting: Laser cutting has smooth edges, high precision and fast speed, ensuring product quality.

● Strong stability: The laser cutting beam is stable, the power is uniform, the working stability is strong, and the cutting effect is consistent.

● High safety: The closed design protects laser radiation and reduces the risk of workers being harmed by laser.

● Green and environmentally friendly: There is no need to use coolant, cooling gas, etc., and no waste gas, waste water, or waste residue is produced, which complies with environmental protection requirements.

● Strong flexibility: The equipment can adjust parameters according to different processing needs to achieve customized processing and has strong adaptability.

● High efficiency: Laser cutting speed is fast and work efficiency is high, suitable for mass production and customized processing needs.

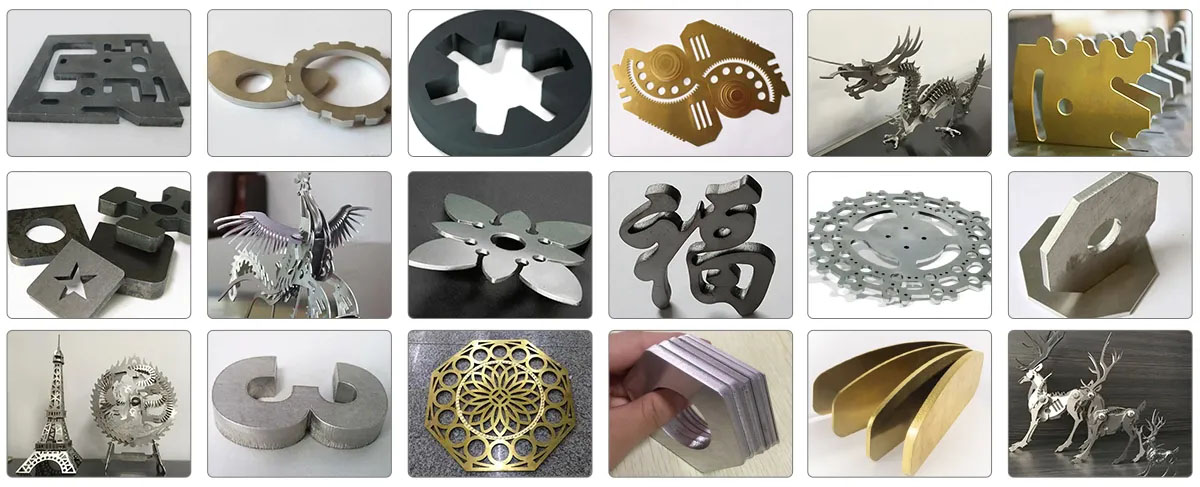

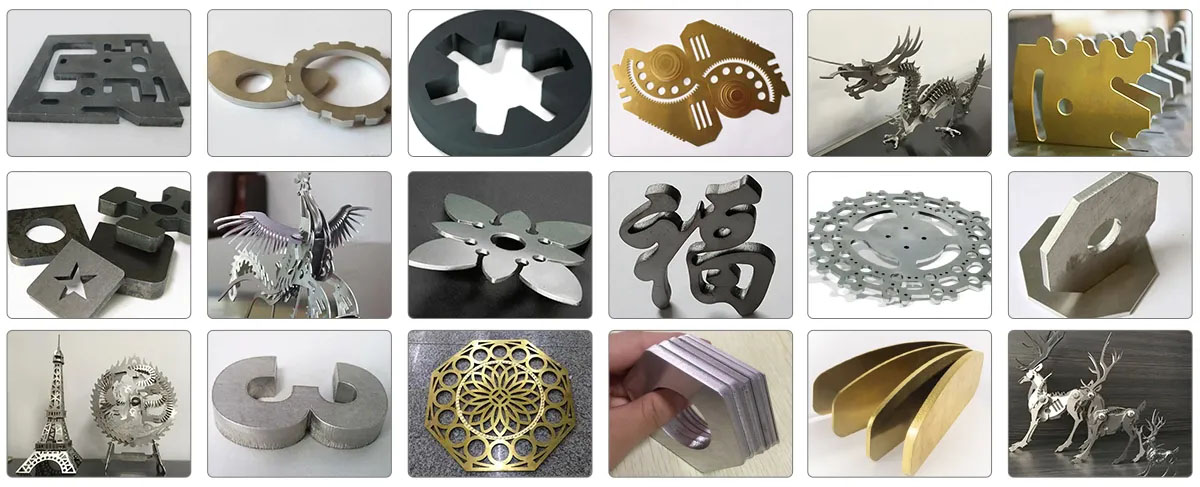

Application materials of laser engraver for metal for sale

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating, zinc plate, metallic copper, brass and other kinds of metals.

Application industry of laser engraver for metal for sale

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of laser engraver for metal for sale

Model | ST-FC3015G/ST-FC4020G/ST-FC1560G/ST-FC6020G/ST-FC6025G |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 1500*6000mm, 2000*6000mm, 2500*6000mm) |

Laser power | 1000W-20KW |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Laser wave length | 1064nm |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Maximum speed | 120m/min |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Equipment power | 8KW(not include laser generator and chiller) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc) |

Machine weight | 7500KG |

Machine dimension (L*W*H) | 8850*3210*2100mm |