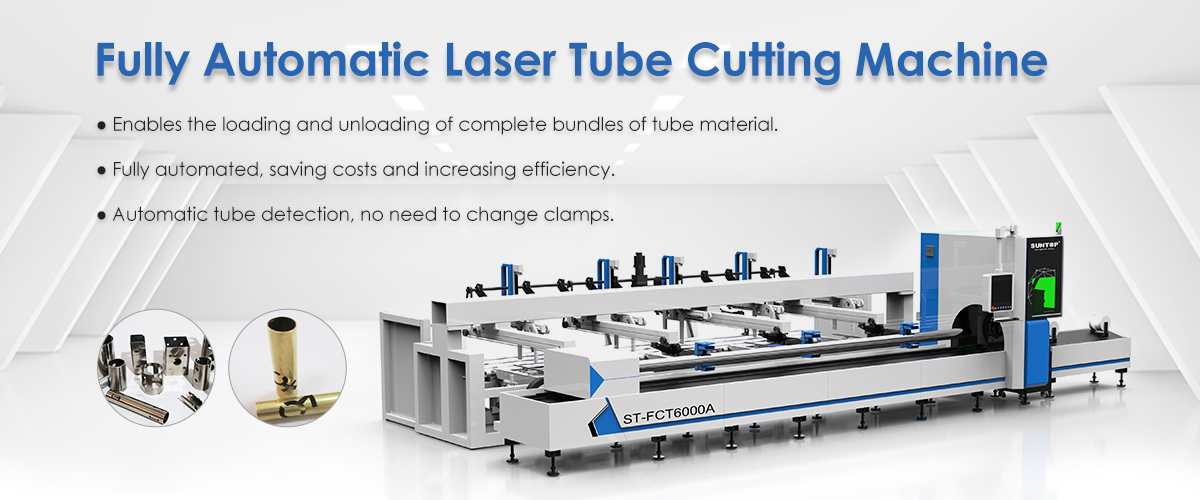

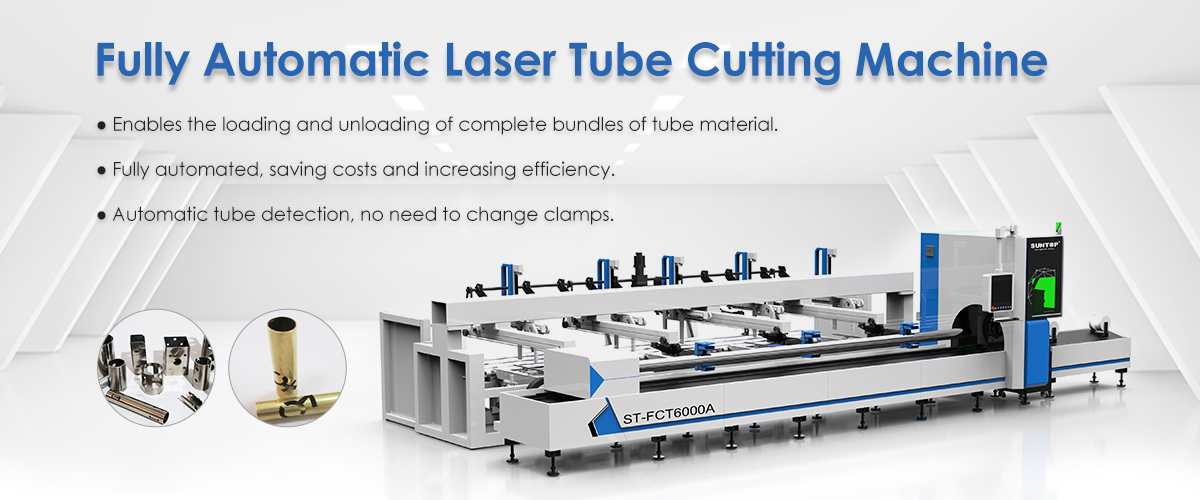

Details Product Parameters Samples Video

Features of laser cutters for metal

1. The system includes automatic feeding and automatic unloading. The automatic feeding system is seamlessly connected with the laser pipe cutting machine through the numerical control system to realize the hoisting and feeding of the whole bundle of pipe materials.

2. High performance, using imported packaged fiber laser, stable performance, good beam quality, high precision, life span up to 100,000 hours.

3. It adopts precision rack and rack transmission mode, which is easy to maintain and basically maintenance-free.

4. Chuck diameter and fixture can be customized according to the specific specifications of the pipe provided by the customer.

5. Pneumatic chuck structure, automatic clamping, automatic positioning center, automatic push and turn, etc.

6. Using the special software for pipe cutting, it can design or process graphics or text in real time, which is flexible and convenient, effectively saves materials and improves cutting efficiency.

Details of laser cutters for metal

1. Fully automatic loading and unloading device

Automatic feeding

After the whole bundle of pipes enters the feeding device, it realizes intelligent material separation and loading, and seamlessly connects with the fiber laser cutting machine to ensure that only one pipe is transported to the conveying arm at a time.

automatic uninstall

The finished product automatically falls into the hopper, and the double support bearings assist in supporting the extra long tube.

2. Fractional automatic support installation

The intelligent pipe support design is adopted to solve the deformation problem during the cutting process of long pipes.

3. Fixture design

Both sides are designed with pneumatic clamps, which can be automatically adjusted.

4. Wireless Controller

The wireless controller is used to freely control the clamping pressure, the control operation is convenient, and the deformation of the pipe is reduced.

5. Automatic stroke protection

Detect the whole process of cutting head work, quickly feedback the risk and stop. Fixed limit double protection, improve equipment and personal safety, reduce risks

6. Intelligent alarm system

Detect anomalies in advance, reduce hidden dangers, and double the effect of equipment anomaly detection.

Advantages of laser cutters for metal

1. Automatic loading and unloading, double the efficiency and greatly save labor costs.

2. Equipped with a pneumatic custom chuck, which can realize symmetrical independent double-action clamping. The clamping process does not require intervention and adjustment. The structural design is simple and stable. It can clamp rectangular tubes, round tubes, oval tubes, triangular tubes, and polygonal tubes. , I-beam and channel steel and other profiles

3. The equipment has power failure memory function, back cutting function, fault automatic alarm, emergency stop function, fault content automatic display function

4. Professional typesetting nesting software and laser cutting system, with unique functions such as graphic intelligent typesetting, automatic positioning of pipe center and sharp corner smoothing.

5. Modular design, can be customized according to customer needs.

Laser cutters for metal application

Application materials

Laser cutting, drilling, slotting, arc cutting, engraving, etc. can be performed on square tubes, round tubes, oval tubes, special-shaped tubes, angle steel, channel steel, H-shaped steel, etc. It is suitable for cutting stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickled steel, galvanized pipe, metal copper, brass and other rare metal pipes.

Application industry

Widely used in furniture industry, construction industry, kitchen and bathroom supplies, lighting equipment, automobile manufacturing, medical equipment, hardware processing, fitness equipment, mold laser cutting, aerospace, machinery, handicrafts, tool processing, decoration and other industries.

Parameters of laser cutters for metal

Model | ST-FCT6000A/ST-FCT3000A |

Laser power | 1000W-20KW |

Laser wavelength | 1064nm |

Elector-optical conversion efficiency | 25%-30% |

Cutting thickness | 0.5-30mm (depend on the actual laser power) |

Cutting seam width | 0.1-1.3mm (depend on the actual thickness of metals) |

Repeated positioning accuracy of the machine tool | ±0.02mm/1000mm |

Positioning accuracy of the machine tool | ±0.03mm |

Max. idle moving speed | 100meter/min |

Max. acceleration | 1.2G |

Max. loading weight | 3000KG |

Single pipe Max. weight | 100KG (when air pressure is 6 bar, every meter≤16KG) |

Tailing length | ≥160mm |

Pipe processing range | 20mm≤Round pipe≤210mm, square pipe (20mm-150mm) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 9000KG |

Machine dimension | 12000*2450*2400mm (L*W*H) |