Product Parameters Samples Video

Advantages of laser cut copper advantages

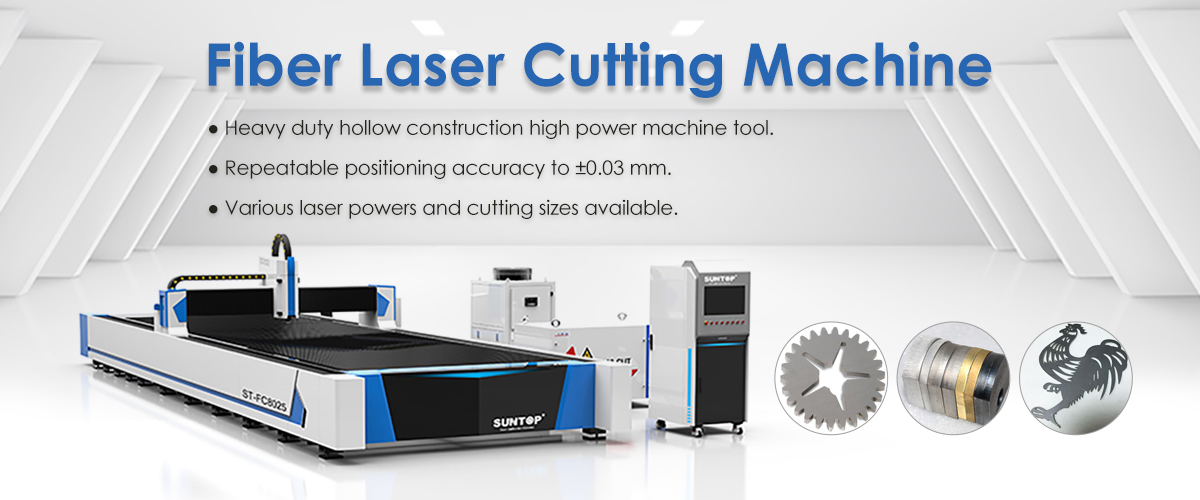

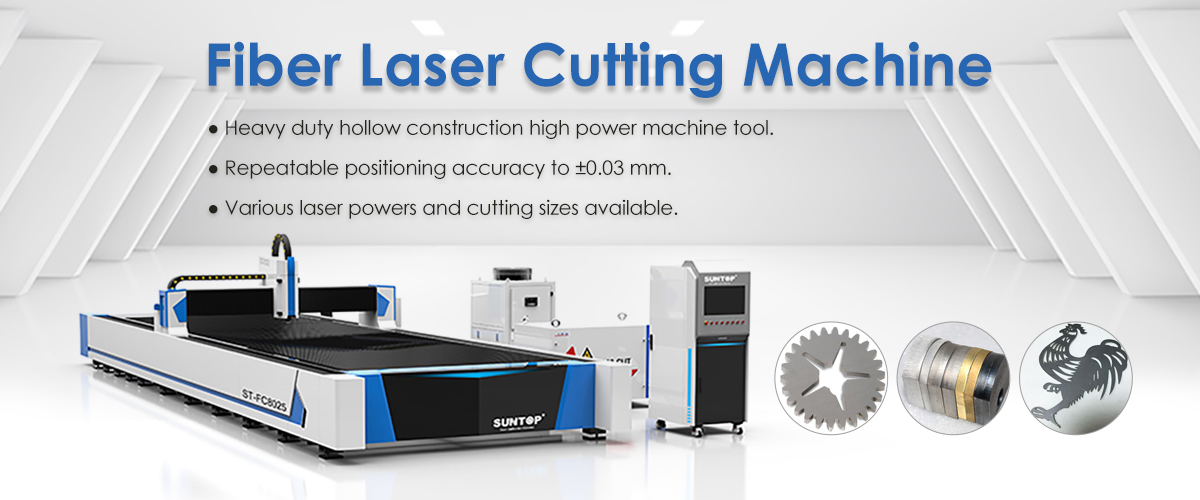

The fiber laser cutting machine can cut high-reflection materials such as brass and copper by using higher laser power and using auxiliary gas to increase the cutting speed.

1. The whole machine adopts gantry rack and pinion double-drive structure and strengthened aluminum alloy beam; the main components adopt Siemens, Schneider, SMC and other imported famous brands. Advanced equipment ensures reliable and stable effect of cutting copper.

2. Professional laser cutting software with graphic layout and sharp corner smoothing processing function, automatic measurement and precise cutting, saving manpower, which can realize high-speed cutting, punching and marking function.

3. Fast cutting speed, high degree of automation, simple operation, low labor intensity, no pollution.

4. High cutting quality and precision. Laser cutting machine is a non-contact mechanical method, and the damage to the material is almost zero. As the laser cutting machine adopts advanced accessories, the equipment is more stable in operation, the cutting accuracy is more accurate, the error even reaches 0 accuracy, and the cutting surface is flat and smooth. For some demanding industries, it can not only save cost but also save processing time.

Notes of laser cutting copper

● When processing copper materials, first understand the specific materials, copper materials are divided into many kinds, generally brass, copper for a wide range. Secondly, then familiar with its thermal conductivity to set the cutting parameters of the metal laser cutting machine. In addition, you can increase the auxiliary gas - oxygen or nitrogen.

● In general, metal laser cutting machine processing of highly reactive materials will be a lot of damage to the laser lens, so generally cutting materials such as copper, try to process thin plates in the 2mm or less. Adding oxygen auxiliary gas, which helps the laser oxidation of copper, can improve the processing speed of metal laser cutting machine and cutting performance.

● When adding nitrogen auxiliary gas, it is recommended to cut copper materials below 1mm, so as to ensure the cutting, so that the cutting surface is smooth and clean.

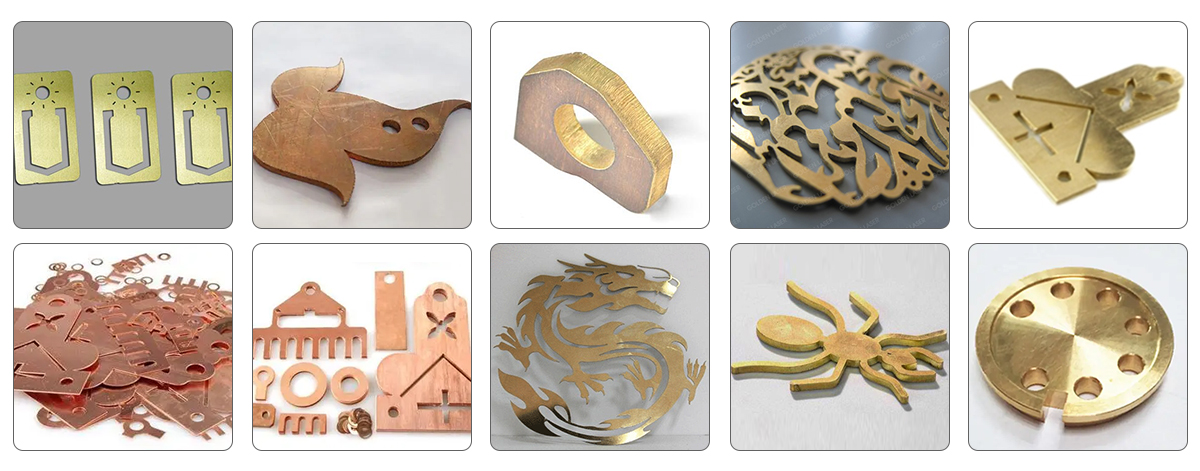

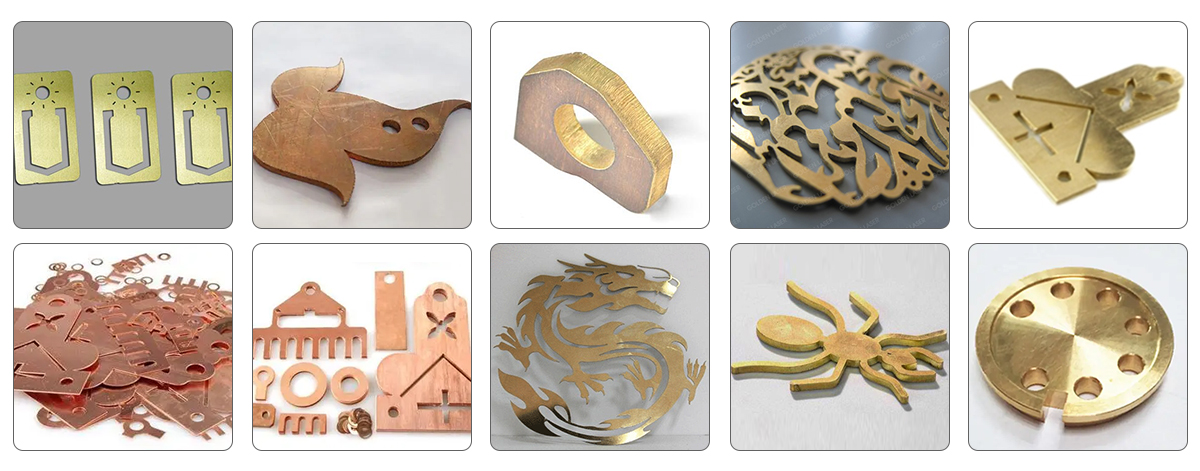

Laser cutting copper application

Application materials

Mainly used for laser cutting of brass, red copper, carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, galvanized sheet and other metal materials.

Application industry

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal external processing, Various manufacturing and processing industries such as kitchenware processing.

Parameters of laser cutting copper

Machine model | ST-FC3015/ST-FC3013/ST-FC4020/ST-FC6020/ST-FC4015/ST-FC6015 |

Working area | 1500*3000mm/1300*3000mm/4000*2000mm,/6000*2000mm/4000*1500mm/6000*1500mm (support customization) |

Laser power | 1000W - 20KW |

Transmission system | Double rack & pinion and servo drive |

Maximum speed | 60m/min |

Positioning accuracy | ±0.03mm/1000mm |

Repositioning accuracy of clamp | ±0.02mm/1000mm |

Format | LXD, DXF, PLT, AI, NC etc. |

Working environment | 0-45℃, Humidity ≤ 80%, non-condensing |

Equipment power | 8KW (not include laser generator and chiller) |

Power supply | Three phase 380V/50Hz or 60Hz |

Total weight | 3000Kg |

Overall size | 5010*2260*1900mm |