According to the current development of the industrial processing industry, fiber laser cutting machine is one of the widely used cutting equipment. Its advantages are relatively obvious compared to traditional cutting, with energy saving, fast and other advantages, loved by the industry.

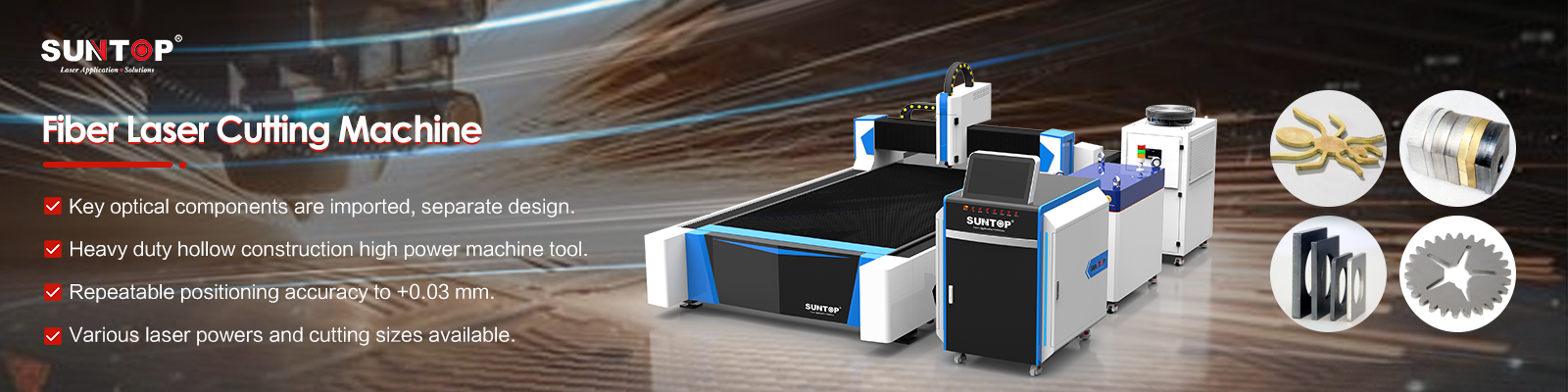

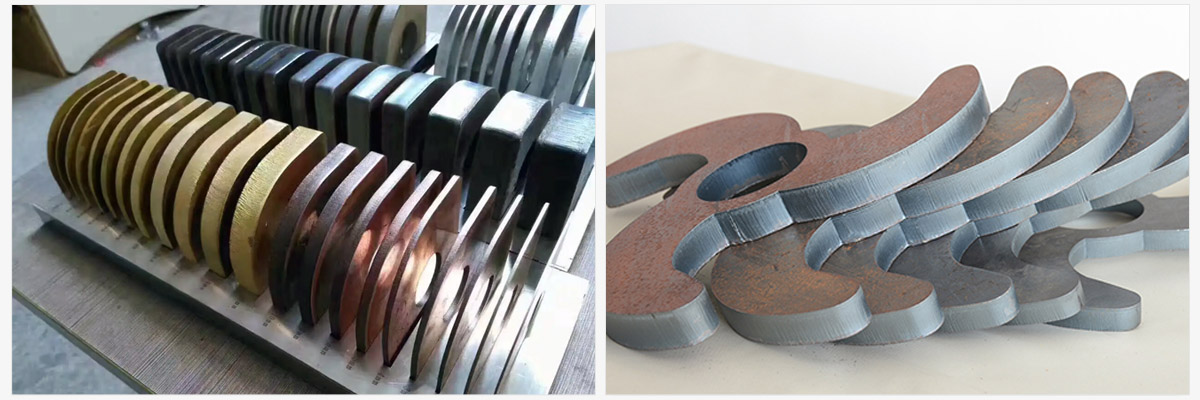

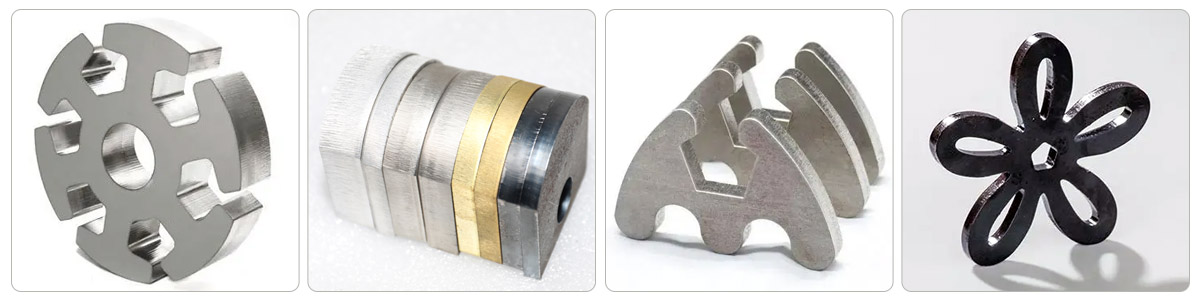

Fiber laser cutting machine is now a more common metal cutting equipment, it can be multi-thickness, multi-process cutting of metal plates, especially to deal with the cutting process in charge of a great advantage, fiber laser cutting machine by a special fiber laser cutting head, high-precision condenser tracking system, fiber laser and other components.

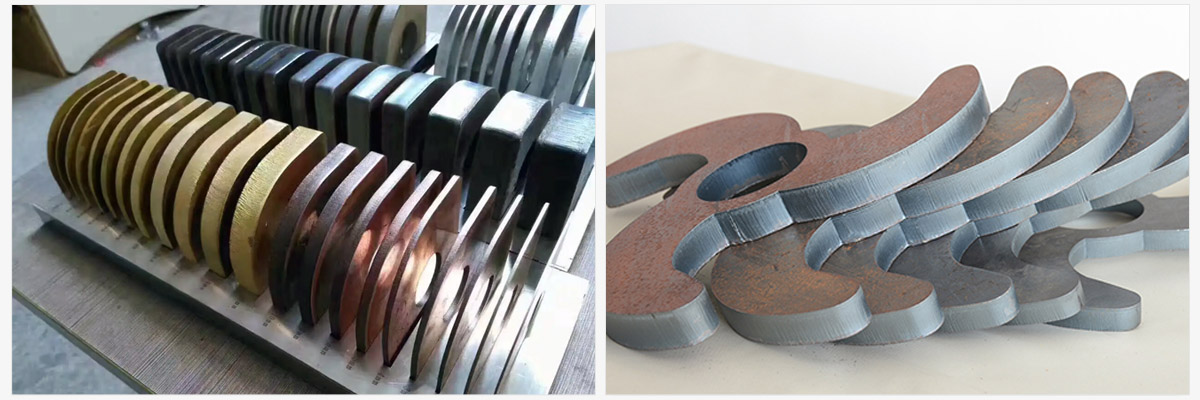

Fiber laser cutting machine equipment is widely used in metal processing. Mechanical equipment manufacturing and automotive parts production and manufacturing and other production of metal raw materials have production and processing requirements in the production. Therefore, the enterprise in the purchase of fiber laser cutting machine, product quality is particularly important, so the manufacturer's selection of an important part. Then how to choose fiber laser cutting machine equipment manufacturers, improve enterprise production efficiency?

Enterprises can be based on mastering their own manufacturing scope, materials, laser cutting regulations, and then clear must buy fiber laser cutting machine model specifications, production and processing width, for the subsequent acquisition of advance preparation.

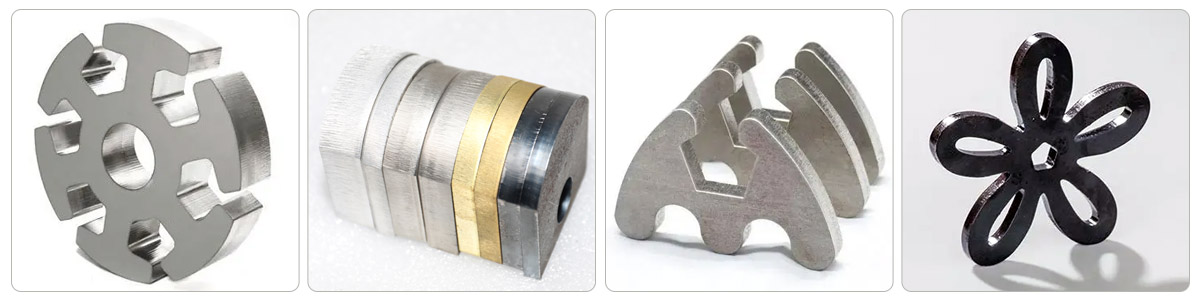

Laser cutting process has a wide range of applications, metal laser cutting process, medical equipment, automotive industry, fitness equipment, agricultural machinery and many other fields.

Laser cutting equipment manufacturers produce fiber laser cutting machine, the width can be customized according to the size of the enterprise's own products, can also be made into a double exchange of large format to cope with the high demand for production efficiency of the enterprise, basically every product can be customized in accordance with the needs of the enterprise.

In today's highly competitive market environment, the choice of suitable fiber laser cutting machine equipment manufacturers for enterprises to improve productivity is critical. The following will analyze how to choose the right manufacturer from several aspects for you to realize the improvement of production efficiency.

1. Technical strength

When choosing a fiber laser cutting machine equipment manufacturer, the first thing to consider is its technical strength. Whether the manufacturer has advanced production equipment and technical team, and can provide high-quality products and technical support.

2. Brand reputation

Understanding the manufacturer's brand reputation and customer reviews is an important reference factor for selection. Choosing a manufacturer with a good reputation can improve the trust of cooperation and ensure the quality of equipment and after-sales service.

3. Cost-effectiveness

In addition to the price of the equipment itself, you also need to consider the maintenance cost of the equipment, energy consumption and other factors. Choosing a cost-effective manufacturer can reduce production costs and improve the competitiveness of the enterprise.

4. Customization capabilities

Enterprises have different production needs, choose a manufacturer with customization capabilities can be customized according to the actual needs of the equipment, improve production efficiency and product quality.

5. After-sales service

Good after-sales service can ensure the stable operation of the equipment, solve problems in a timely manner, reduce downtime in production and improve production efficiency.

6. Technological innovation

Choose to focus on technological innovation manufacturers, you can get newer and faster equipment and technical support, to maintain the competitive advantage of enterprises.

Choosing the right fiber laser cutting machine equipment manufacturers is the key to improving productivity. Comprehensive consideration of technical strength, brand reputation, cost-effectiveness, customization capabilities, after-sales service and technological innovation, you can find the most suitable partner for the enterprise to achieve the improvement of production efficiency.

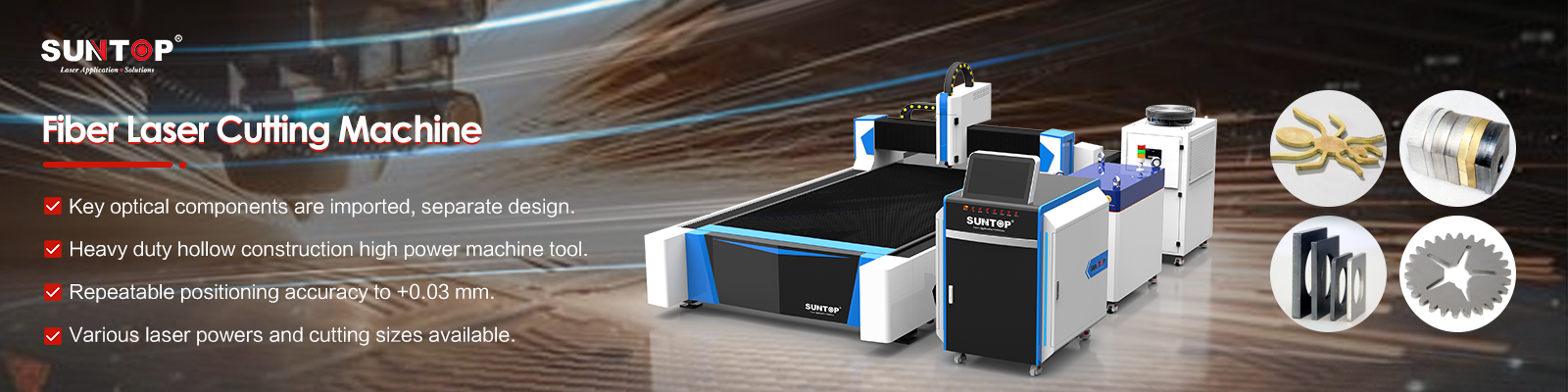

Technology is developing, the times are progressing, the metal processing industry is becoming more and more popular, the production process is now mostly automated technology mechanical automation, in which there will be our Suntop laser fiber laser cutting machine, for the enterprise's production and manufacturing cost savings, improve high efficiency, reduce the production cycle.