Details Product Parameters Samples Video

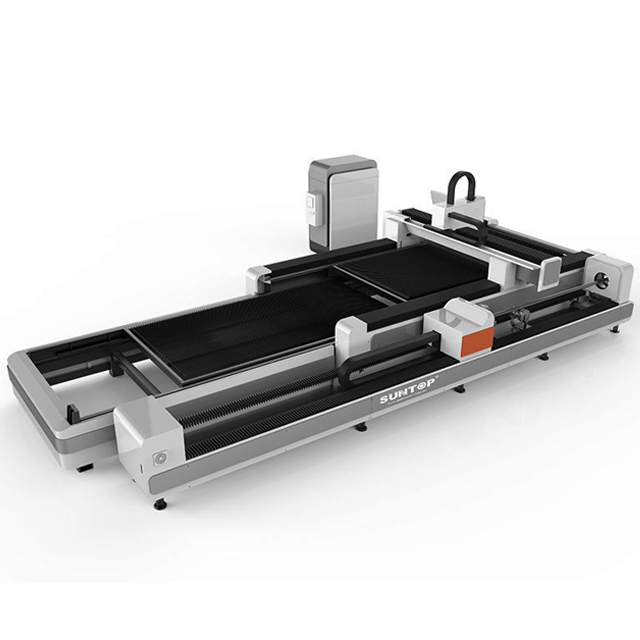

Features of fibre laser cutting machine

1. The machine adopts a parallel exchange structure, the size of the workbench and the length of the pipe can be customized, and the machine can be fully enclosed according to customer requirements.

2. The machine is equipped with a pneumatic rotating shaft for cutting square tubes, round tubes, rectangular tubes and channel steel, and the central power automatically clamps, pushes and positions, realizing real intelligence.

3. Carry out loading, unloading and cutting of plates at the same time, which greatly improves work efficiency.

4. The automatic tracking system can realize the calibration and automatic tracking of the corrugated metal plate.

5. The heavy-duty machine structure adopts cross-welded steel plates to support the upgrade of laser power in the later stage.

Details of fibre laser cutting machine

1. Exchange platform

● The rack and pinion transmission system has good rigidity and higher precision, which saves waiting time for loading and unloading.

● Compared with the traditional sprocket and chain drive method, the loading time is shorter and the efficiency is higher. The inverter controls the exchange motor, and the platform can be replaced within 10 seconds.

2. Fully automatic pneumatic chuck

● Wireless handheld control box, one-button release and clamping of claws, convenient and efficient;

● The auxiliary chuck adopts double-row rollers, which has a more uniform clamping force than single-row rollers, and reduces the influence of pipe deformation and swing on cutting accuracy;

● Pneumatic clamping, the air pressure remains constant after clamping, the clamping force is large and constant, and the pipe does not loosen or slip;

● 220 pairs of full-stroke pneumatic chucks, full-stroke clamping, no need to change jaws, easy to operate;

● Double-action self-centering chuck can realize quick clamping of special-shaped tubes such as rectangular tubes and elliptical tubes. Special tube types need customized jaws.

3. Heavy machine tools

The whole machine adopts a thick carbon steel structure, and the weight of a single machine tool reaches 4 tons. The hollow structure of the high-power machine tool effectively reduces the heating area during laser cutting. The machine tool will not be deformed during long-term use, and at the same time it ensures good cutting accuracy and greatly improves the stability of the machine tool. It will not be deformed after at least 20 years of use.

4. Auto focus laser cutting head

● No manual focus required

The software automatically adjusts the focusing mirror to realize automatic perforation and cutting of plates with different thicknesses. Automatically adjusting the focus lens is ten times faster than manual adjustment.

● Larger adjustment range

Adjustment range -10mm~+10mm, precision 0.01mm, suitable for different types of plates from 0~20mm.

● Long service life

Both the collimating mirror and the focusing mirror are equipped with water-cooled heat sinks to reduce the temperature of the cutting head and increase the service life of the cutting head.

Advantages of fibre laser cutting machine

1. One machine is multi-purpose, which can not only meet the customer's cutting requirements for flat plates, but also meet the cutting requirements of round pipes and special-shaped pipes (square steel, flat iron, channel steel, square pipe), with high cost performance.

2. Imported helical rack and pinion with high precision, high load, high reliability and long-term stable operation.

3. High-speed parallel exchange platform, double worktables can be exchanged at the same time, the transmission mode is stable and reliable, and the exchange time is shortened.

4. The cutting precision is high, the speed is fast, the cutting kerf is narrow, the cutting surface is smooth and burr-free, which improves the product quality.

5. Special software can design or process graphics or text in real time. Flexible and convenient operation.

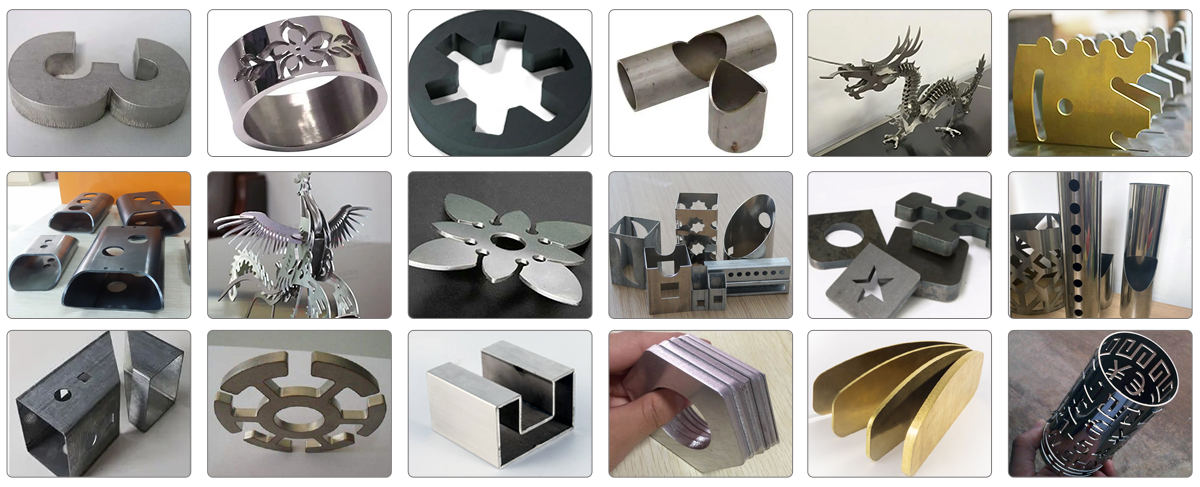

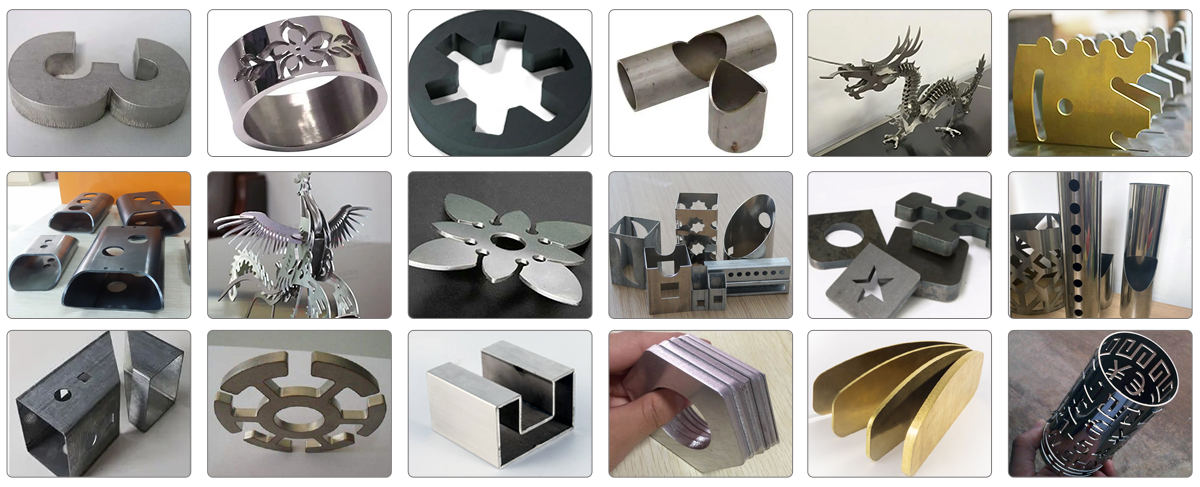

Fibre laser cutting machine application

Application materials

Mainly cutting a variety of metal plates and tubes, suitable for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of fibre laser cutting machine

Model | ST-FC3015CR/ST-FC4020CR/ST-FC6015CR/ST-FC6020CR |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 6000*1500mm, 6000*2000mm) |

Laser wavelength | 1064nm |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Maximum speed | 120m/min |

Repeat positioning accuracy | ±0.02mm |

Tube cutting standard range | 20mm≤Round tube≤220mm,

20mm≤Square tube≤150mm

Other size can be customized |

Tube cutting standard length | 3000mm/6000mm (other length can be customized) |

Power consumption | <10KW (based on laser power 1000W) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 9000KG |

Machine dimension | 5050*2480*1830mm (L*W*H) |