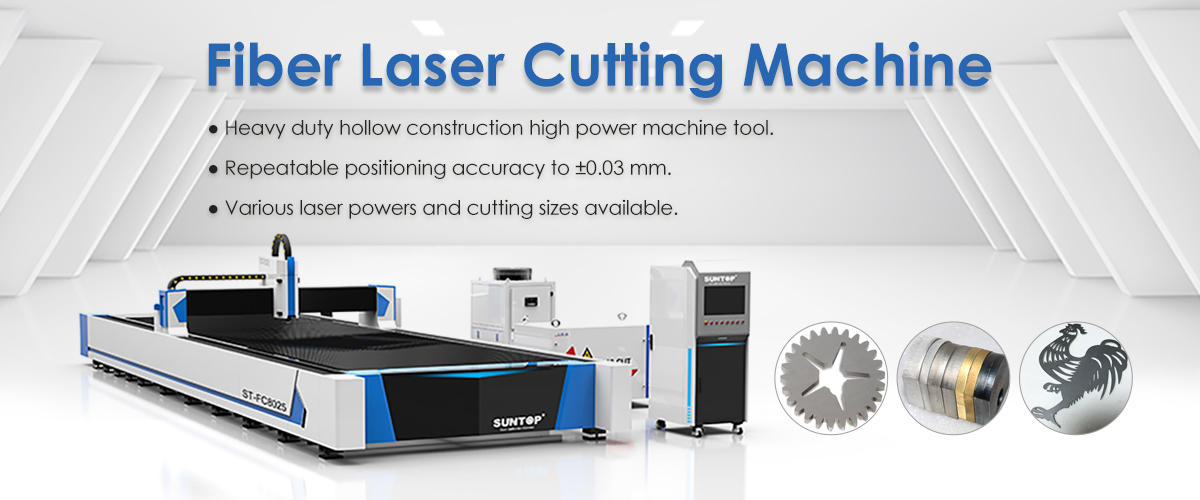

Details Product Parameters Samples Video

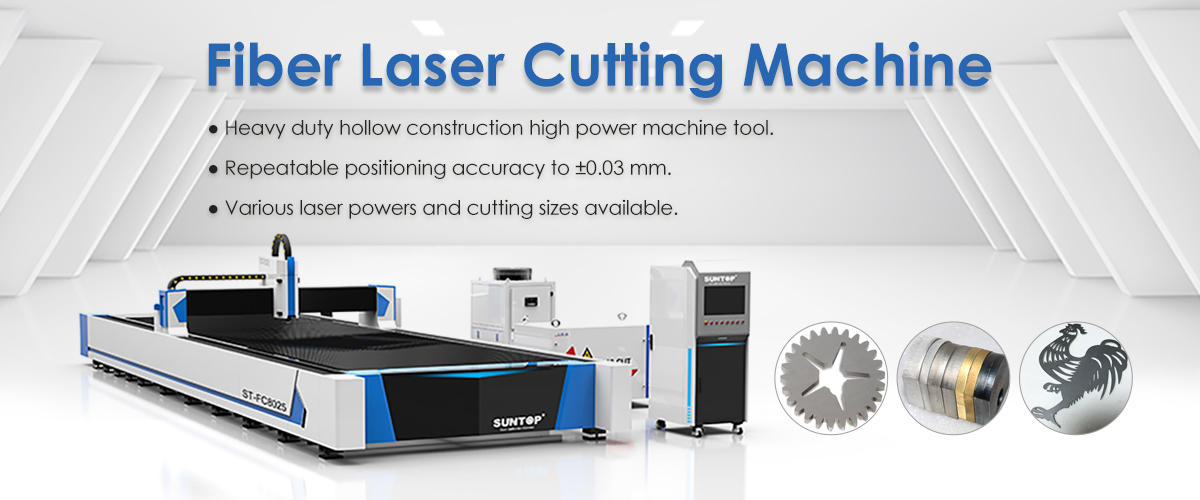

Features of fiber laser cutting machine metal

1. The frame, beam, and workbench are integrally welded, manufactured according to the standard large machine, stress relief annealing, rough machining, and vibration aging treatment. Completely eliminate welding and processing stress, maintain high strength and high precision, no deformation after 20 years of normal use.

2. Both X and Y axes adopt Japanese servo motors, which have high precision, fast speed, large torque, large inertia and stable performance, ensuring the high speed and acceleration of the whole machine.

3. The precision ball screw transmission mechanism is adopted to optimize the control of the numerical control system, which can meet the requirements of precision parts processing, and the dynamic performance is stable, and it can work continuously for a long time.

4. The automatic focusing laser cutting head system is adopted, the cutting head moves with the height of the plate, and the position of the cutting point is always kept unchanged, so that the kerf is flat and smooth, and the section does not need post-processing, which is suitable for cutting flat or curved plates.

5. The mechanical transmission part has been tested and calibrated by laser interferometer many times to ensure that our machine can maintain good and stable accuracy even after several years of use.

6. The optical path system of the laser is stable. After thousands of vibration experiments, the optical path system of the laser is stable.

7. The cutting format is large, suitable for many cutting materials, supports customization of various cutting formats, and is suitable for almost all metal materials.

8. Compatible with a variety of software, design graphics as you like, simple, flexible and easy to operate.

Advantages of fiber laser cutting machine metal

Laser cutting processing, with high precision, fast cutting, not limited to cutting pattern design restrictions, automatic typesetting saves materials, smooth incision, low production cost and other characteristics, will gradually improve or replace traditional metal cutting technology. As the most popular industrial production cutting machine at this stage, the laser cutting machine is generally fully functional for its production and processing materials, and has been gradually introduced into various fields.

(1) High precision, fast speed, narrow slit, small heat-affected zone, smooth and burr-free cutting surface.

(2) The laser cutting head will not touch the surface of the material and will not scratch the workpiece.

(3) The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

(4) Good processing flexibility, can process arbitrary graphics, and can also cut pipes and other special-shaped materials.

(5) It can cut any hard material such as steel plate, stainless steel, aluminum alloy plate, and hard alloy without deformation.

Detail of fiber laser cutting machine metal

◆ High-power hollow structure machine

We use high power hollow structure machine tool, which effectively reduces the heat area during laser cutting, and the machine tool will not be deformed in long-term use, and also ensures good cutting accuracy.

◆ Imported high-performance core accessories

X/Y axis is equipped with imported high performance servo motor and driver to achieve high efficiency and high precision motion control of the transmission system and further improve the cutting performance.

◆ Own core optical patent cutting head

Carefully developed and designed. The optical series mirror set directly affects the spot quality, which enhances the available laser beam energy and optimizes the beam pattern and beam quality, further expanding the cutting performance and stability of the cutting machine.

◆ Independent dust extraction channel design

The built-in independent dust extraction duct system provides strong air suction and efficient dust removal, while greatly reducing the heat impact on the machine.

◆ High precision constant temperature and humidity control system

The electric control cabinet is equipped with high precision constant temperature and humidity control system, which has the function of cooling and maintaining normal temperature to prevent fogging effect and focal point drifting.

Ensure the stable production of the machine, effectively guarantee the efficient and stable operation of the laser and prolong the service life of the laser.

Cutting capacity of fiber laser cutting machine metal (only for reference)

Power | Carbon steel (mm) | Stainless steel (mm) | Aluminum (mm) | Brass (mm) |

| Ultimate thickness | Actual processing thickness | Ultimate thickness | Actual processing thickness | Ultimate thickness | Actual processing thickness | Ultimate thickness | Actual processing thickness |

2KW | 16 | 10 | 8 | 6 | 6 | 4 | 6 | 4 |

3KW | 22 | 12 | 11 | 8 | 8 | 6 | 8 | 6(4) |

4KW | 25 | 14 | 12 | 10 | 10 | 8 | 10 | 8(5) |

6KW | 25 | 16 | 20 | 14 | 16 | 10 | 12 | 10 |

8KW | 40 | 20 | 30 | 18 | 30 | 16 | 16 | 12 |

12KW | 40 | 22 | 40 | 25 | 40 | 20 | 16 | 16 |

15KW | 60 | 25 | 50 | 30 | 50 | 25 | 20 | 18 |

The table above has listed the tables corresponding to different powers in detail. Each material corresponds to the limit thickness and the actual processing thickness. Generally, the thickness of the cut processed by the factory in batches should be based on the actual processing thickness. This will not only guarantee the laser equipment service life and also ensure that the processed materials have good accuracy. If you encounter too thick a plate, you can also cut it, but it must not exceed the limit thickness. If cutting plates of extreme thickness in batches, after a long time, there will be certain errors in the materials, and the life of the laser will be shortened.

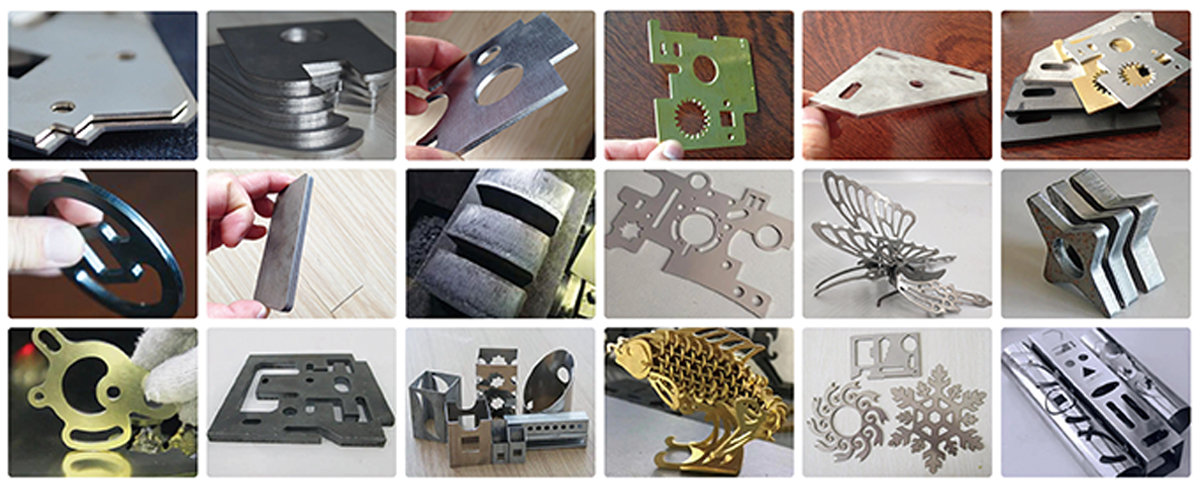

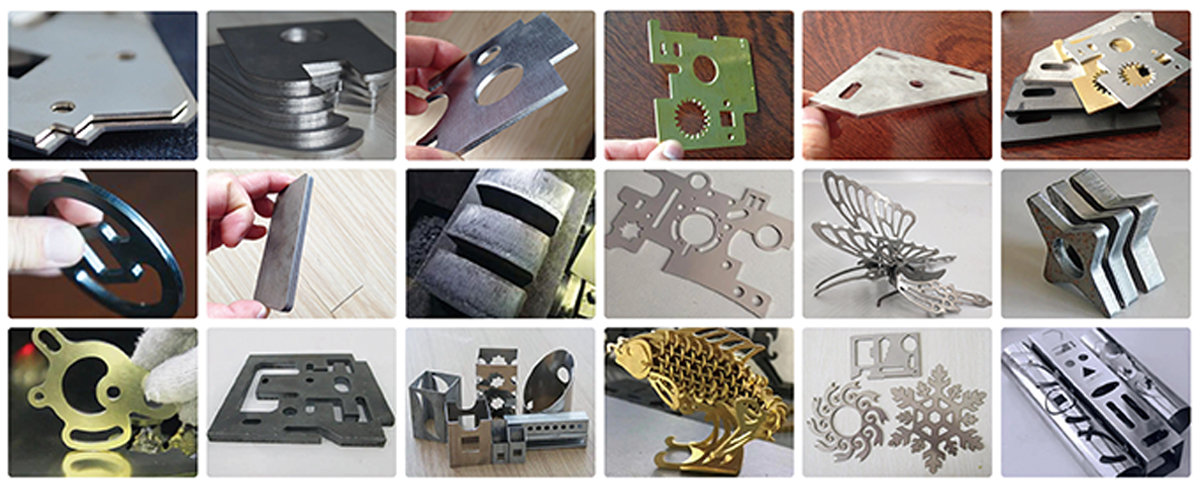

Fiber laser cutting machine metal application

Application materials

Cutting of stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickled sheet, copper, silver, gold, titanium and other metal sheets and pipes.

Application industry

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, crafts and gifts, tool processing, decoration, advertising, metal external processing and other various manufacturing and processing industries.

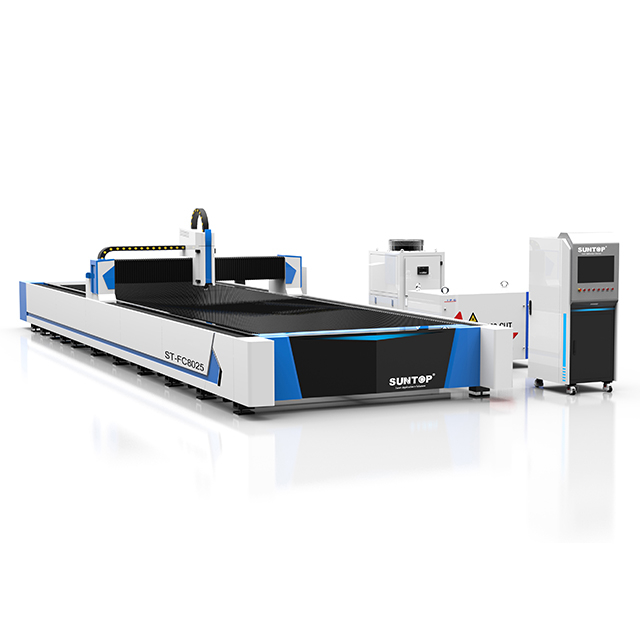

Parameters of fiber laser cutting machine metal

Machine model | ST-FC3015/ST-FC3013/ST-FC4020/ST-FC6020/ST-FC4015/ST-FC6015 |

Working area | 1500*3000mm/1300*3000mm/4000*2000mm,/6000*2000mm/4000*1500mm/6000*1500mm (support customization) |

Laser power | 1000W - 20KW |

Transmission system | Double rack & pinion and servo drive |

Maximum speed | 60m/min |

Positioning accuracy | ±0.03mm/1000mm |

Repositioning accuracy of clamp | ±0.02mm/1000mm |

Format | LXD, DXF, PLT, AI, NC etc. |

Working environment | 0-45℃, Humidity ≤ 80%, non-condensing |

Equipment power | 8KW (not include laser generator and chiller) |

Power supply | Three phase 380V/50Hz or 60Hz |

Total weight | 3000Kg |

Overall size | 5010*2260*1900mm |