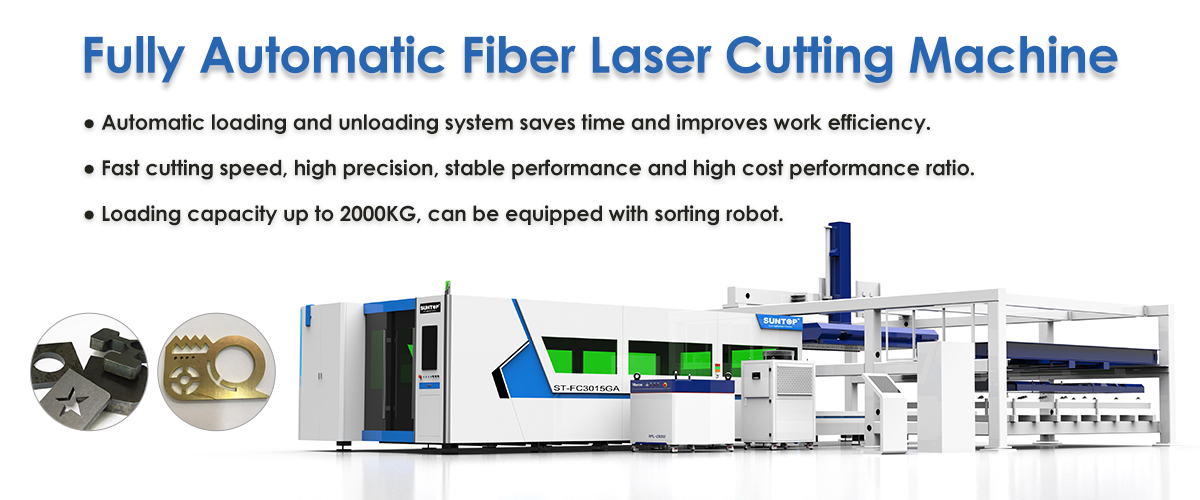

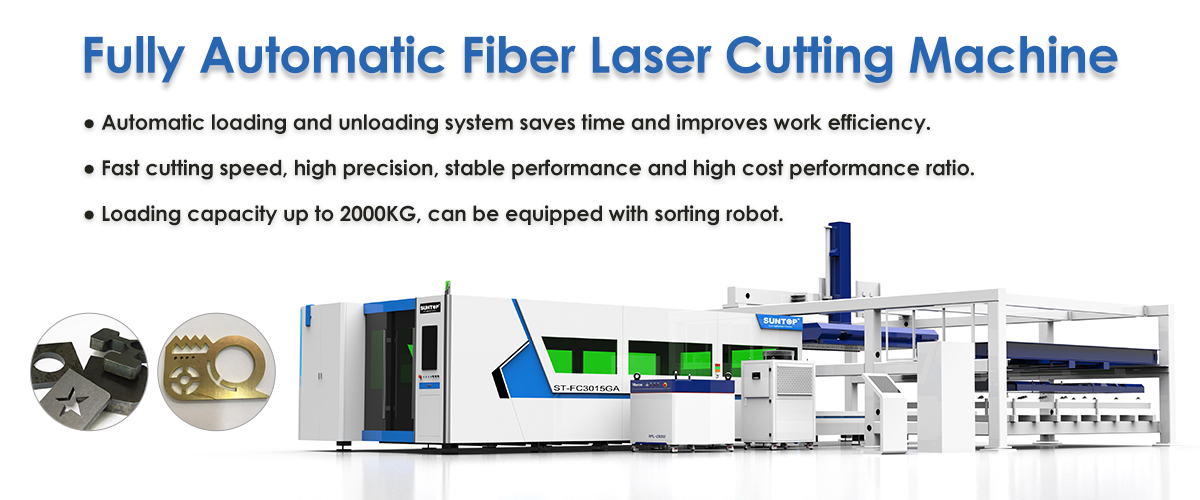

Product Parameters Samples Video

Features of fiber laser cutter head

• Optional height sensor

• -10 mm~ +10mm focal length adjustment range

• The protective lens is equipped with real-time temperature monitoring to reduce the probability of lens overheating

• Adopts drawer-type mirror holder, making it easy and fast to replace the protective lens

• Flexible design to optimize spot size

• Portable and compact structure design

• Modular design can be adapted to various fiber optic interfaces

Auto focus laser cutting head

◆ Without manual focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

◆ Bigger adjustment range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

◆ Long service life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Heavy machine tools

● We use a high-power machine tool with a hollow structure, which effectively reduces the heating area during the laser cutting process. The machine tool will not be deformed after long-term use, and it also ensures good cutting accuracy and greatly improves the stability of the machine. At least use 20 years will not deform.

● Our machine tools are welded with thick steel plates, and the weight of one machine tool alone reaches 4 tons.

The third generation aviation aluminum mast

Manufactured by aerospace standards and extruded by a 4,300-ton press. After aging treatment, its strength can reach 6061 T6, which is the highest strength of all gantry frames. Aviation aluminum has the advantages of good toughness, light weight, corrosion resistance, oxidation resistance, and low density, which greatly improves the processing speed.

Advantages of fiber laser cutter head

1. High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cutting surface without burrs.

2. The laser cutting head will not touch the surface of the material and will not scratch the workpiece.

3. The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is extremely small, and there is no mechanical deformation.

4. Good processing flexibility, can process arbitrary graphics, and can also cut pipes and other special-shaped materials.

5. Modular design, can be customized according to the special requirements of customers.

Fiber laser cutter head application

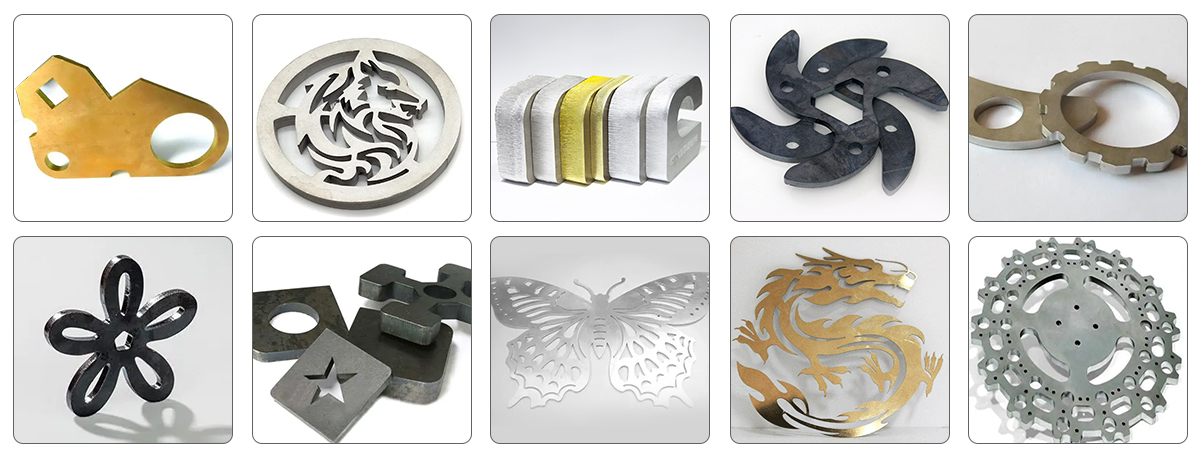

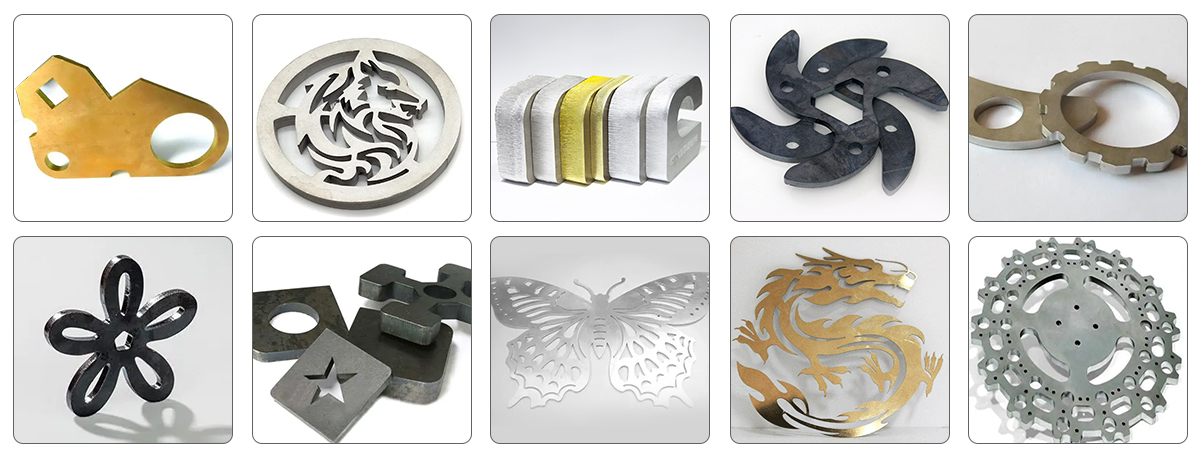

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, alumina-plating, zinc plate, metallic copper, brass and other kinds of metals.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of fiber laser cutter

Model | ST-FC3015GA/ST-FC4020GA/ST-FC6020GA/ST-FC6015GA/ST-FC4015GA |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 6000*2000mm, 6000*1500mm, 4000*1500mm) |

Laser wavelength | 1064nm |

Transmission system | Gear+rails (we have standard brand; we can also produce as your requirements) |

Max cutting speed | 1--30m/min (according to metal material and laser power) |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (the exact data according to whick kind of metals and the corresponding thickness) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 12500KG |

Machine dimension | 8850*3210*2100mm (L*W*H) |