Details Product Parameters Samples Video

Introduction of CNC laser cutting machine

◆ CNC laser cutting machine is a brand new product launched by Suntop laser, the whole machine is guided by Suntop laser technology, the main parts are made of original imported brands, with higher cutting accuracy, faster speed, easier operation, lower cost of use, wider cutting materials, etc.

◆ Combined with the advanced laser cutting technology, it greatly improves the stability of the machine, providing customers with stable laser cutting performance, reducing sheet waste and increasing production capacity. The cutting software is customized by Suntop laser for the machine, easy to learn, easy to use, and easy to operate with one key, just like operating a smartphone.

◆ It has high precision, fast cutting speed, and is not limited by cutting patterns. Automatic nesting has the advantages of material saving, smooth slit, and low processing cost. It will gradually improve or replace traditional cutting process equipment.

Features of CNC laser cutting machine

1. Adopt well-known brand Raycus, MAX, IPG and other fiber lasers. The beam quality is better and more stable, the anti-high reflection ability is stronger, the reliability is strong, and the service life is long.

2. The auto-focusing laser head does not need manual focusing, which is easy to operate. Control the vertical height, auto-focus, quickly complete the high-speed perforation of thick plates, and automatically cut materials of different thicknesses.

3. The bed adopts integral welding structure, rough machining after annealing to eliminate internal stress, and finishing machining with secondary vibration aging treatment, which greatly improves the stability of the machine tool.

4. The gantry beam design is adopted, with light weight, good rigidity, good dynamic performance and stable operation. The fully enclosed dust-proof structure greatly improves the service life of the built-in rack and pinion and linear guide. Anti-corrosion, anti-oxidation, good toughness, good flexibility.

5. Imported rack and pinion are used to adapt to various conditions of use, dust-proof, and ensure long-term high-precision movement.

6. The maintenance cost is low, and the photoelectric conversion efficiency is over 30%, which greatly saves power consumption during work, saves operating costs, and achieves the highest production efficiency.

7. Energy saving and environmental protection, equipped with professional dust removal equipment. Low noise, clean, safe and pollution-free.

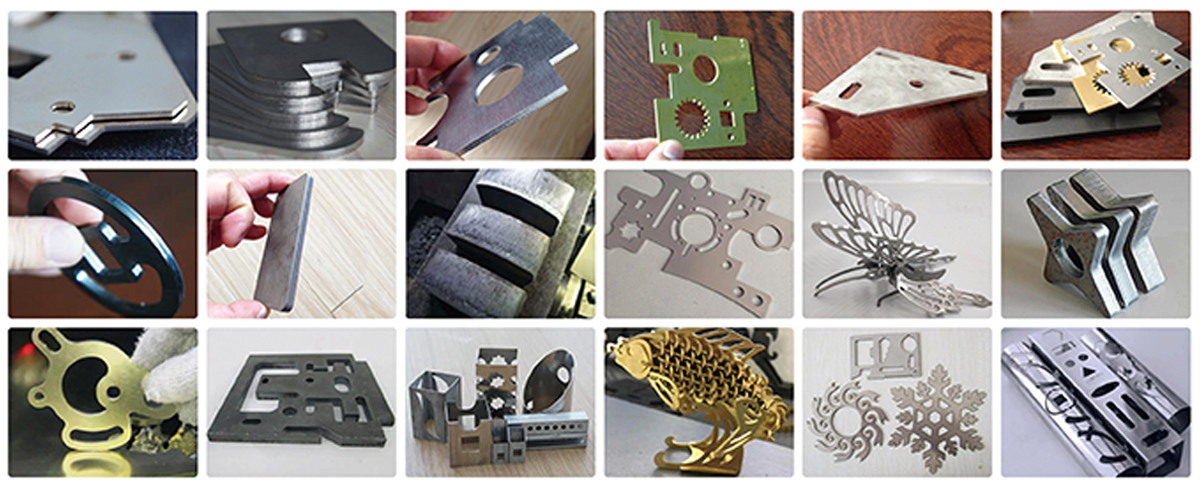

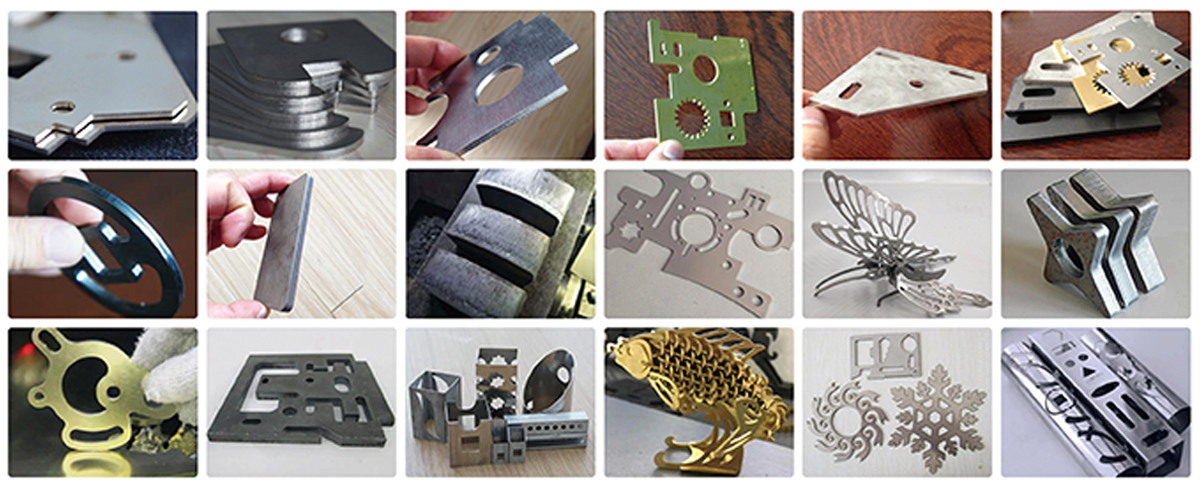

CNC laser cutting machine application

Application materials

It can be used to cut various metal materials such as carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, galvanized sheet, etc.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of Chinese fiber laser cutter

Model | ST-FC3015G/ST-FC4020G/ST-FC1560G/ST-FC6020G/ST-FC6025G |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 1500*6000mm, 2000*6000mm, 2500*6000mm) |

Laser power | 1000W-20KW |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Laser wave length | 1064nm |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Maximum speed | 120m/min |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Equipment power | 8KW(not include laser generator and chiller) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc) |

Machine weight | 7500KG |

Machine dimension (L*W*H) | 8850*3210*2100mm |