Details Product Parameters Samples Video

Features of Chinese fiber laser cutter

1. The high-power hollow structure machine tool is used to effectively reduce the heating area during laser cutting. Our machine tools are all welded with thick steel plates, and the weight of only one machine tool has reached 4 tons. The stability of the machine is greatly improved, and it will not be deformed for at least 20 years.

2. The mechanical transmission part has been tested and calibrated by the laser interferometer many times to ensure that our driver can maintain good and stable accuracy even after several years of use.

3. Cameras are installed on the front and rear workbenches of the machine, which can effectively monitor the working status of the workbench.

4. Using professional Raytools fiber laser cutting head, imported optical lenses, smaller focus spot, more precise cutting line, ensuring higher efficiency and better processing quality. Equipped with non-contact automatic follow function to ensure the best focus and cutting effect.

5. Professional laser Cypcut cutting software, computer operation, easier to operate.

6. Compatible with a variety of software, can design a variety of graphics or text instant cutting, simple, flexible and convenient operation

7. The machine can be equipped with automatic nesting function.

Laser cutting machine is the use of invisible light beam instead of the traditional mechanical knife, with high precision, fast cutting, not limited to cutting pattern restrictions, automatic layout to save material, smooth kerf, low processing costs, etc., will gradually improve or replace the traditional metal cutting process equipment. The mechanical part of the laser head and the work without contact, in the work will not cause scratches on the work surface; laser cutting speed, smooth and flat kerf, generally without subsequent processing; cutting heat-affected zone is small, the plate deformation is small, narrow slit (0.1mm ~ 0.3mm); no mechanical stress in the kerf, no shear burr; high processing accuracy, good repeatability, no damage to the material surface; CNC programming, can be processed Arbitrary plane figure, can be a large width of the whole board cutting, no need to open the mold, economic and time-saving. Excellent processing performance should be matched with excellent design, quality from inside to outside, in order to enhance its sense of value.

Details of Chinese fiber laser cutter

1.The cutting accuracy of the machine, the key is the accuracy of the mechanical structure, all body frame after flatness planing and milling processing, into the workshop assembly test.

2.Conventional model body frame, after planing and milling, painting and testing, stock to be installed, shorten the delivery cycle and improve the delivery capacity.

3. Metal plate and pipe cutting, applicable to different platforms and clamping and transportation methods, single platform, double platform interaction method, pipe clamping and feeding, etc. can be used.

4. Adopt rack, reducer, screw and other transmission structure, good rigidity and stability, fine cutting effect.

5. After the completion of important steps such as mechanical structure, planing and milling, painting, installation, electrical control and testing, the laser part will be issued in time when it is completed.

Advantages of Chinese fiber laser cutter

1. Laser cutting machine is the use of invisible light beam instead of the traditional mechanical knife, with high precision, fast cutting, not limited to cutting pattern restrictions, automatic layout to save material, smooth kerf, low processing costs, etc., will gradually improve or replace the traditional metal cutting process equipment.

2. The mechanical part of the laser head and the work without contact, in the work will not cause scratches on the work surface;

laser cutting speed, smooth and flat kerf, generally without subsequent processing.

3. Cutting heat-affected zone is small, the plate deformation is small, narrow slit (0.1mm ~ 0.3mm); no mechanical stress in the kerf, no shear burr;.

4. High processing accuracy, good repeatability, no damage to the material surface.

5. CNC programming, can be processed Arbitrary plane figure, can be a large width of the whole board cutting, no need to open the mold, economic and time-saving.

6. Excellent processing performance should be matched with excellent design, quality from inside to outside, in order to enhance its sense of value.

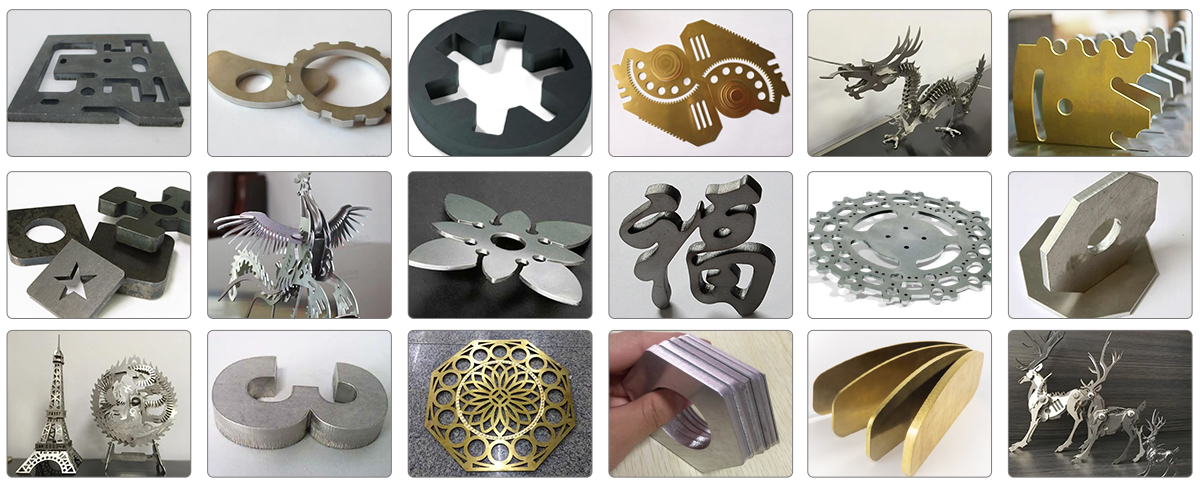

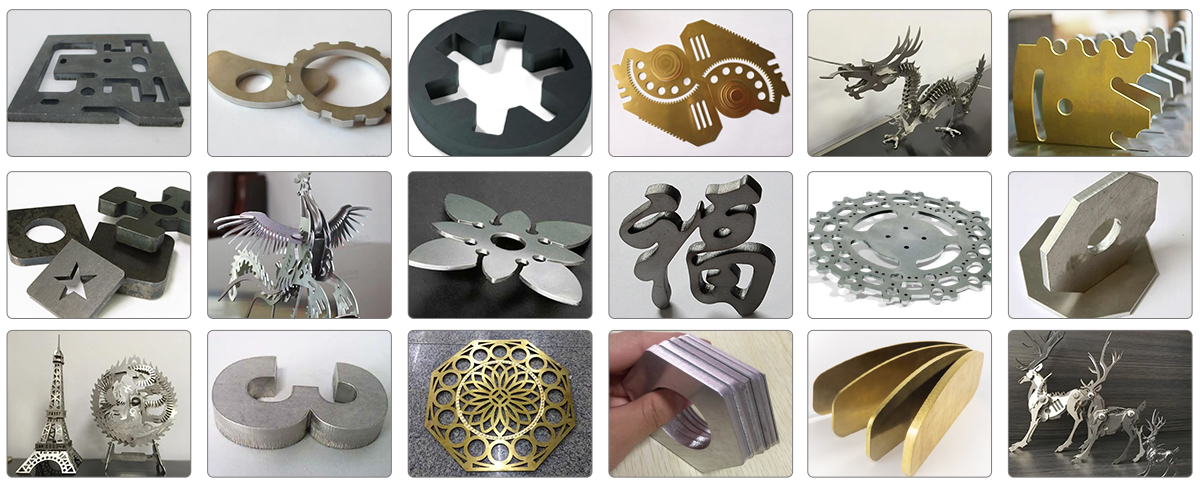

Chinese fiber laser cutter application

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, aluminum-plating, zinc plate, metallic copper, brass and other kinds of metals.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of Chinese fiber laser cutter

Model | ST-FC3015G/ST-FC4020G/ST-FC1560G/ST-FC6020G/ST-FC6025G |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 1500*6000mm, 2000*6000mm, 2500*6000mm) |

Laser power | 1000W-20KW |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Laser wave length | 1064nm |

Laser source | Raycus Brand (MAX, IPG can be choosed) |

Maximum speed | 120m/min |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 0.5G |

Equipment power | 8KW(not include laser generator and chiller) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 220V±10%, 50-60Hz / 380V±10%, 50-60HZ |

Applicable material | All metal (stainless steel, brass, aluminum, titanium steel, etc) |

Machine weight | 7500KG |

Machine dimension (L*W*H) | 8850*3210*2100mm |