Details Product Parameters Samples Video

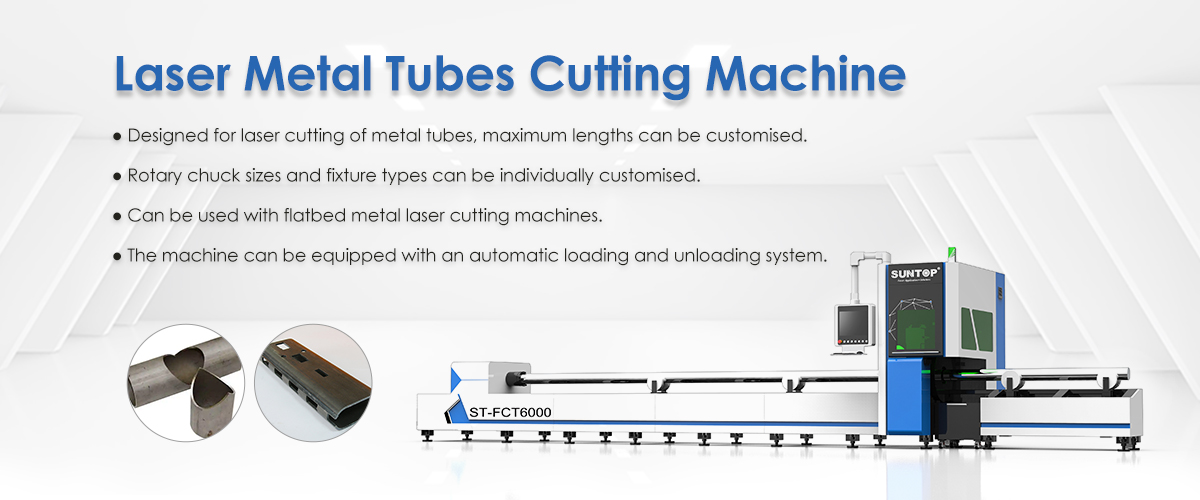

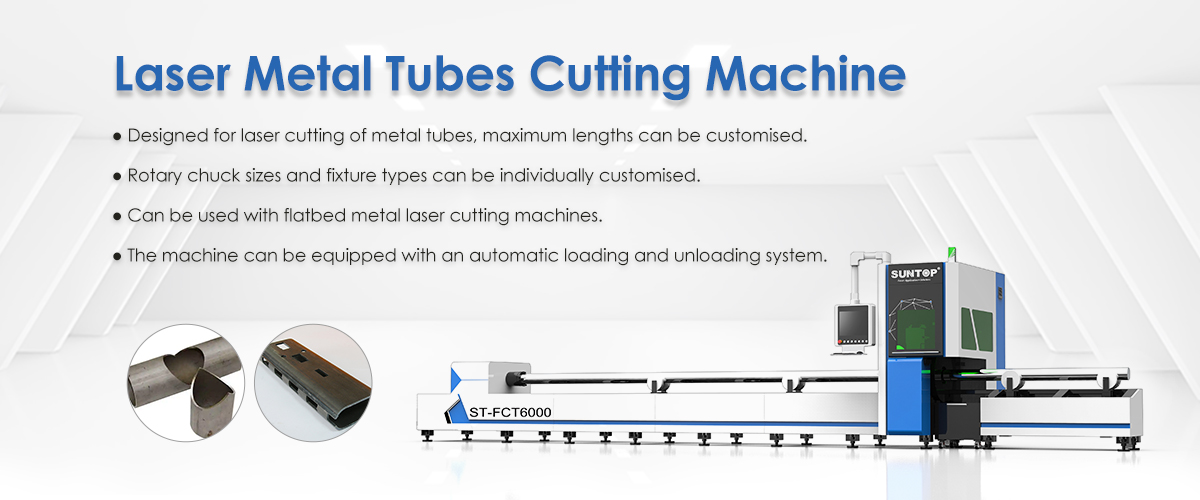

Features of laser tube cutting machine

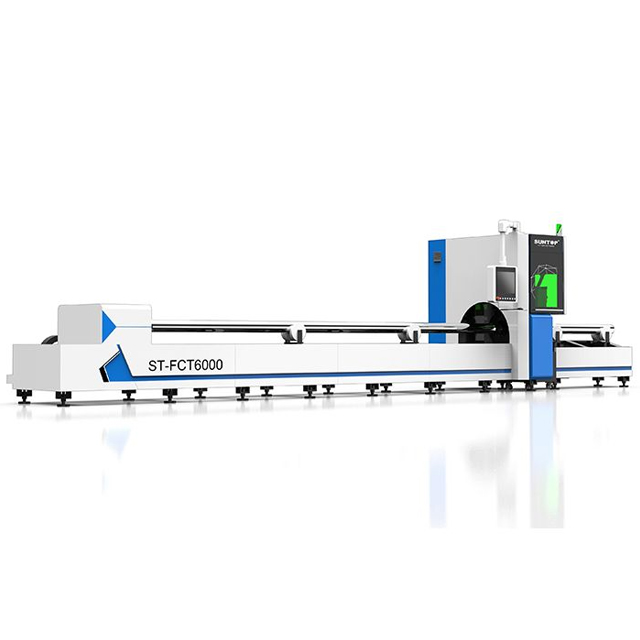

1. The front and rear adopt double pneumatic chuck design, and the rear chuck is equipped with an air blowing device to reduce the slag attached to the pipe wall during the cutting process.

2. The clamping strength can be adjusted arbitrarily, and different strengths can bear different loads, so as to avoid the deformation of the thin pipe clamp and the looseness of the thick pipe clamp.

3. The humanized design of the whole machine makes the best use of raw materials while improving the cutting efficiency, reduces production costs, and achieves "0" tailings.

4. Intelligent pipe cutting design, pneumatic support, large load capacity, and helical gear transmission effectively reduce the noise and vibration caused by gear engagement during chuck transmission, ensuring the stability of cutting.

5. Adopt gantry type double gear rack, double servo motor drive, high torque, high inertia output, effectively improve the production efficiency of the equipment.

6. Applicable to all kinds of metal pipes: round pipe, square pipe, rectangular pipe, oval pipe, waist pipe, D-shaped pipe, hexagonal pipe, special-shaped pipe, etc.

Details of laser tube cutting machine

1. Clamping design

Driven by a motor, the front and rear are clamped by electric chucks, the center is automatically adjusted, the clamping range is wide, and the operation is simple and stable.

Gear transmission mode, higher transmission efficiency.

2. Cast aluminum beam

The overall cast aluminum beam is refined through artificial aging and solid solution treatment, so that the beam has excellent integrity, rigidity and good toughness.

Light weight, anti-corrosion, anti-oxidation, low density, under the premise of satisfying the precision, it can realize the rapid cutting of various graphics.

3. Heavy bed design

A high-power machine tool with a hollow structure is welded with thick steel plates, and the weight of a single machine tool reaches 4 tons. Effectively reduce the heated area during laser cutting. Long-term use of the machine tool will not deform, but also ensure good cutting accuracy, greatly improving the stability of the machine. It will not be deformed after at least 20 years of use.

4. Laser cutting head

No need to manually focus, the software automatically adjusts the focusing lens. Control the upper and lower heights to realize automatic perforation and cutting of plates with different thicknesses. Automatic adjustment of the focus lens is ten times faster than manual adjustment.

5. Automatic lubrication system

Ensure the normal high-speed operation of the equipment, with abnormal alarm, liquid level alarm, etc., to ensure accuracy and extend the service life of the transmission.

6. Smart operating system

Professional intelligent control system with automatic nesting function.

The performance is stable, the operation is fast, and it supports a variety of common file formats.

The simple and fast operating system, one-key import of multiple types of cutting graphics, and accurate cutting instructions make the user experience better.

Advantages of laser tube cutting machine

1. The cutting speed is fast and the precision is high, and it can realize the precision cutting of opening, cutting, intersecting lines and various complex shapes that are difficult to achieve by conventional methods.

2. The special laser cutting head for pipes, together with the special cutting system and nesting software, can realize the long-term cutting function of various pipe fittings.

3. Various pipes with different diameters can be switched freely without changing fixtures.

4. Support bevel cutting, double chuck clamping, suitable for all kinds of irregular pipe fittings.

5. The double sprocket structure has a longer service life, and the flexible track has strong adaptability to deformation for rough steel pipes.

6. High flexibility for pipe cutting, professional cutting software, can cut any shape programmed on the metal pipe, and can complete cutting in any direction, reducing the number of molds used.

Laser tube cutting machine application

Application materials

Suitable for cutting the stainless steel, carbon steel, silicon steel, aluminium alloy, titanium alloy, galvanized steel, pickle steel, aluminium-plating Zinc tubes, metallic copper, brass and other rare metal tubes.

Application industry

It is widely used in laser cutting processing of various metal tubes, such as mold laser cutting, electronic applications, aviation, machinery, elevator, automobile, turbine, cutting tool, subway parts, petroleum machinery, food machinery, handicraft, tool processing, decoration, lamp post, steel furniture, decoration, advertising, metal outside processing and other metal tube related industries.

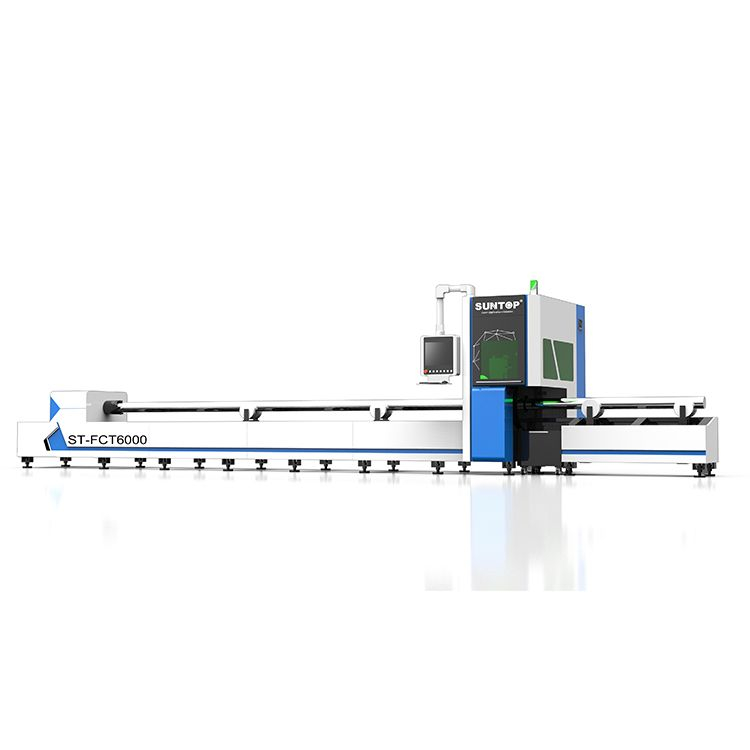

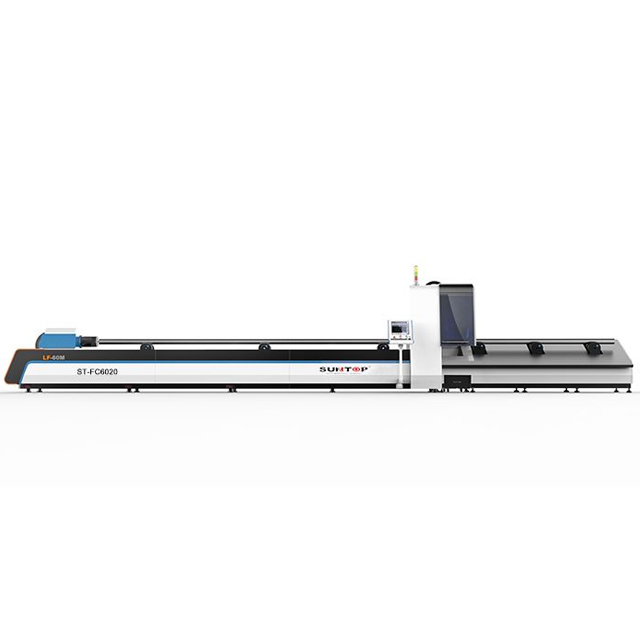

Parameters of laser tube cutting machine

Model | ST-FCT6000/ST-FCT3000 |

Laser power | 1000W-20KW |

Laser wavelength | 1064nm |

Repeat positioning accuracy | ±0.02mm |

Tubes cutting capacity | Square tubes: 20-150mm (can be customized)

Round tubes: 20-220mm (can be customized) |

Tubes length | 3 meters or 6 meters (optional) |

Chuck type | Manual chuck type or pneumatic self-centering chuck (optional) |

Power consumption | 6KW (based on laser power 1KW) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 4850Kg |

Machine dimension | 12000*1650*2280mm (L*W*H) |