Details Product Parameters Samples Video

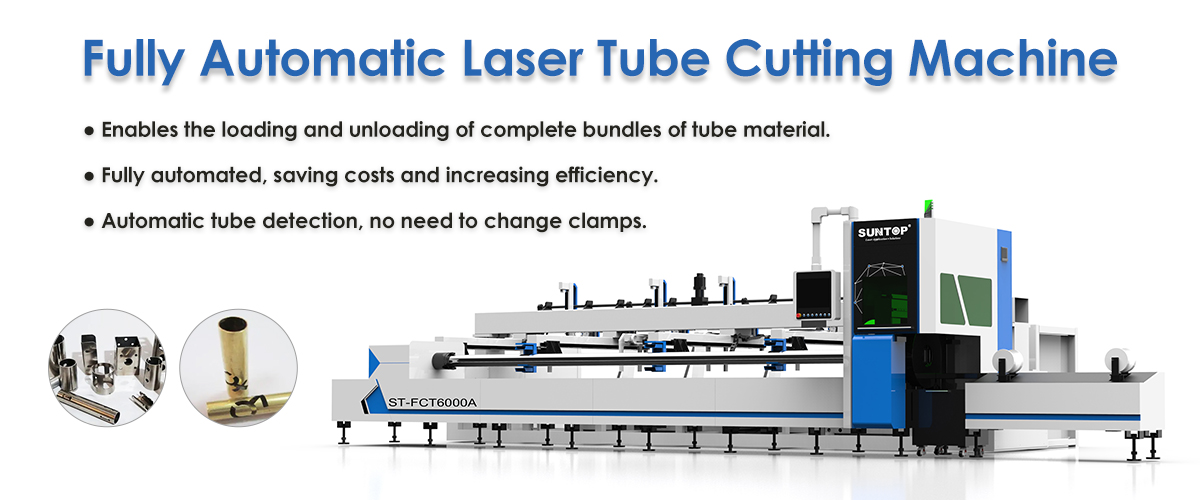

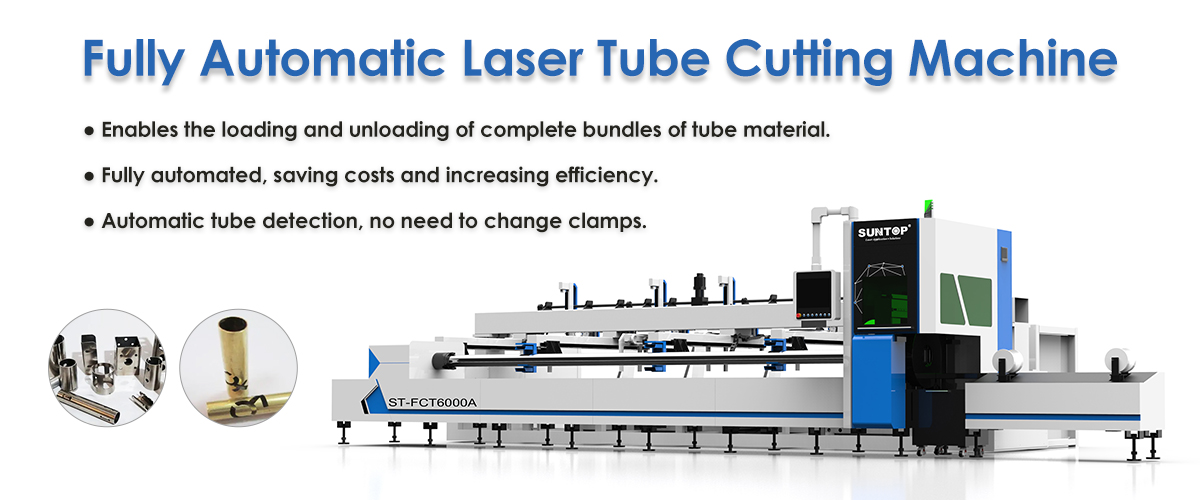

Features of automatic laser tube cutting machine

1. The system includes automatic feeding and automatic unloading. The automatic feeding system is seamlessly connected with the laser pipe cutting machine through the numerical control system to realize the hoisting and feeding of the whole bundle of pipe materials.

2. High-speed automatic CNC laser pipe cutting machine, which can perform high-speed and high-quality laser cutting on round pipes, square pipes and other profiles. .

3. The automatic unmanned working cycle, with the help of fast loading and unloading functions, makes the machine tool have a high utilization rate.

4. There is no need to make molds, just draw the drawings from the computer, and the final product can be cut out immediately, which can quickly develop new products and greatly save costs.

5. This machine has an automatic tracking system, which can cut not only flat surfaces, but also various uneven surfaces.

6. The intelligent alarm system detects abnormalities in advance, reduces hidden dangers, and doubles the effect of equipment abnormality detection.

7. The wireless controller is used to freely control the clamping pressure, the control operation is convenient, and the deformation of the pipe is reduced.

Details of automatic laser tube cutting machine

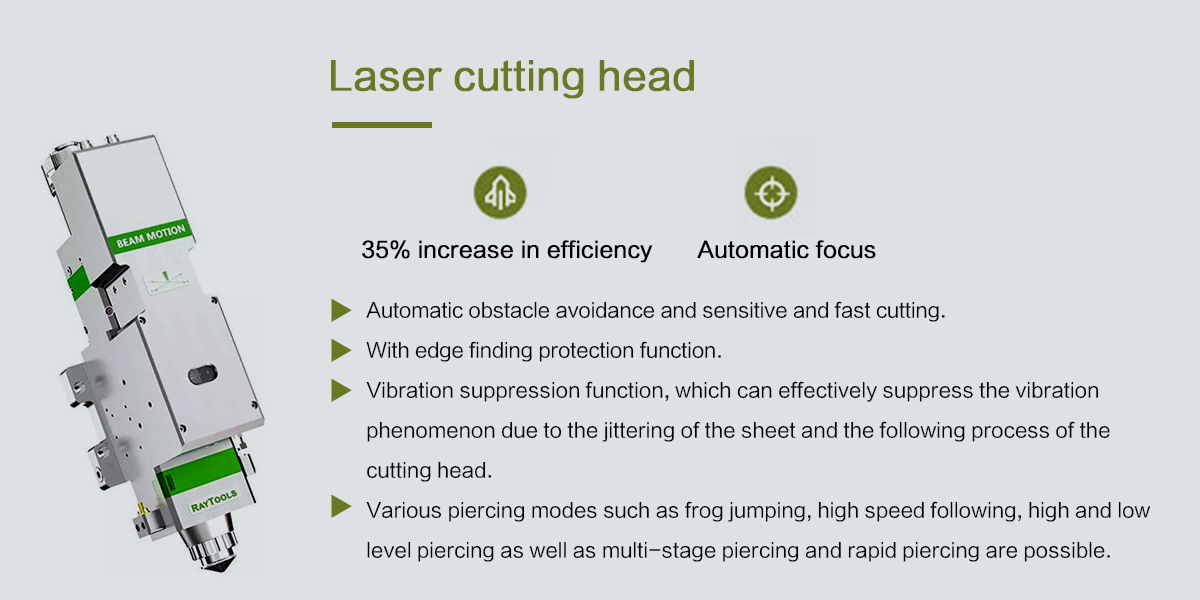

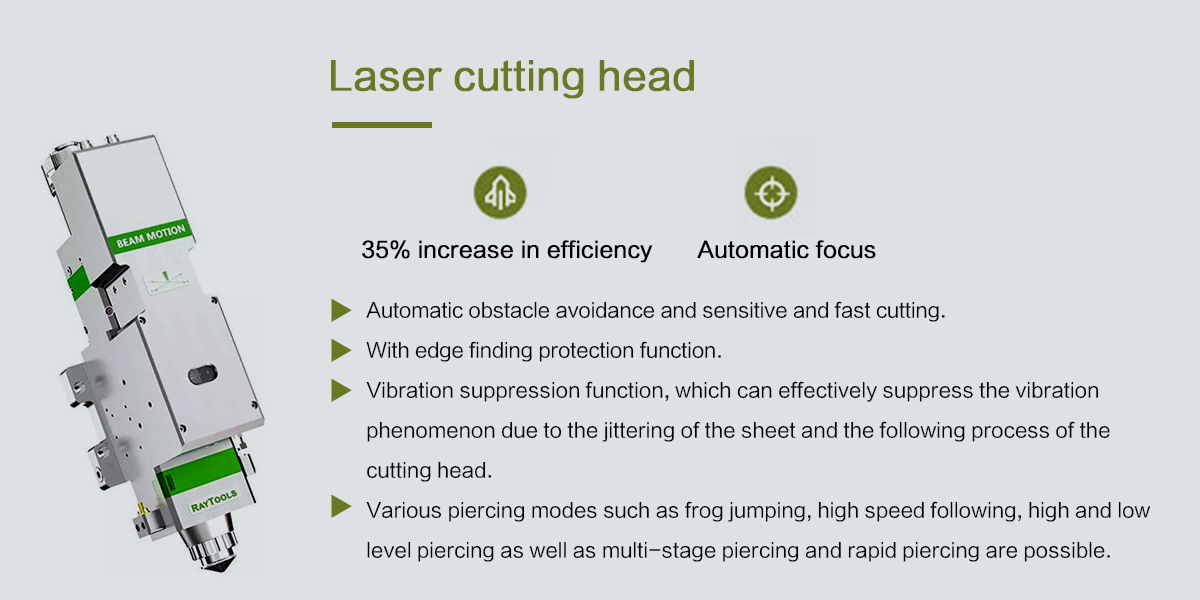

1. Autofocus laser cutting head

There is no need to manually focus, the software automatically adjusts the focusing lens to realize automatic perforation and cutting of plates with different thicknesses.

Both the collimating mirror and the focusing mirror are equipped with water-cooled heat sinks to reduce the temperature of the cutting head and increase the service life of the cutting head.

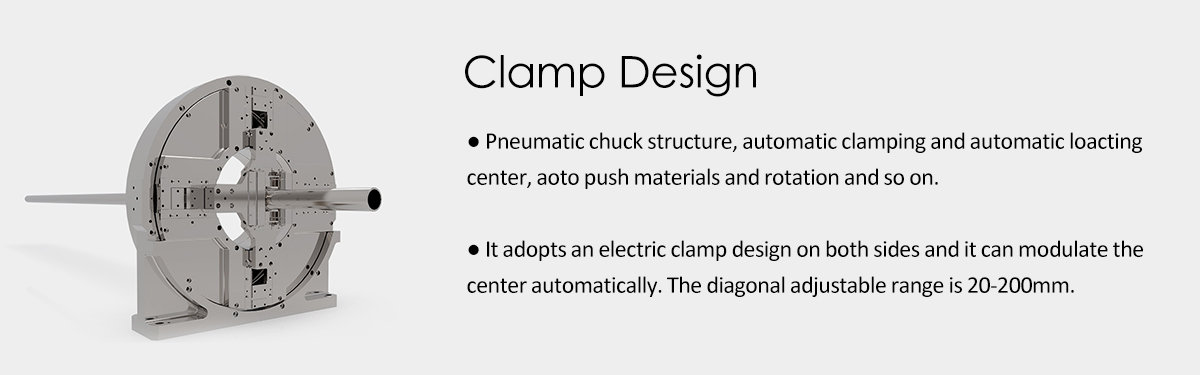

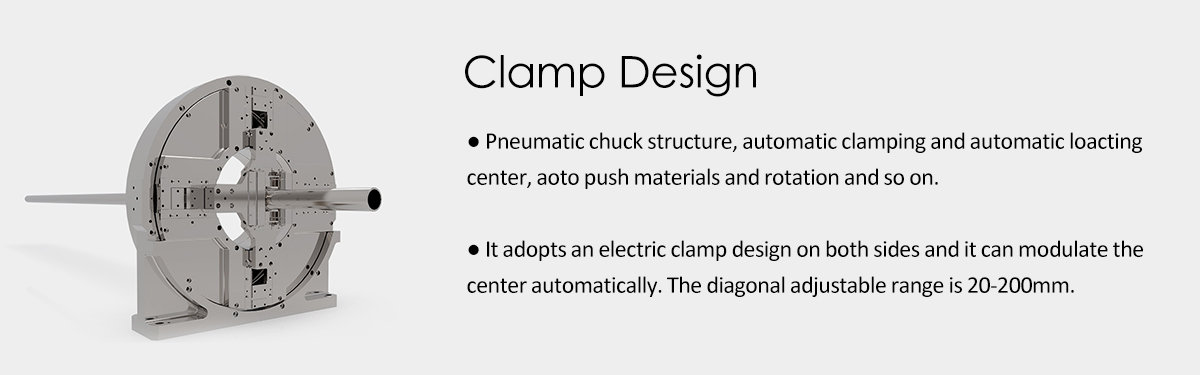

2. Fixture design

Both sides are designed with pneumatic clamps, which can be automatically centered, and the diagonal adjustable range is 20-300mm.

3. Fractional auto support installation

The intelligent pipe support design is adopted to solve the deformation problem during the cutting process of long pipes.

4.Fully automatic loading and unloading device

Automatic feeding

After the whole bundle of pipes is put into the feeding device, it realizes intelligent material separation and loading, and seamlessly connects with the fiber laser cutting machine to ensure that only one pipe is transported to the conveying arm at a time.

Automatic uninstall

The finished product automatically falls into the silo, and the double support-bearing assists in supporting the super long tube.

Advantages of automatic laser cutting machine

1. High precision: suitable for cutting pipes and various craft characters and patterns.

2. The thermal shock of laser cutting tube is small, not easy to deform, the cutting surface is smooth and beautiful, and no secondary treatment is required.

3. The cost of laser cutting is very low, almost no consumables, maintenance-free, and the life of the laser generator can reach 100,000 hours.

4. Modular design, matching with mainstream laser cutting machines in the market, and can be customized according to customer needs.

5. The whole machine is highly integrated, with good system performance and long life. The mutual clamping chuck can automatically detect the pipe, and it is not necessary to replace the fixture when changing various pipes. It can precisely control the cutting accuracy of the pipe.

Automatic laser cutting machine application

Application materials

Suitable for steel tubes, carbon steel, stainless steel, alloy steel, aluminium, copper, titanium, etc., good pipe cutting effect for all kinds of alloy materials with high hardness and easy brittleness (depending on the actual power).

Application industry

It can meet the cutting processing needs of most shapes of pipes. Used in agricultural machinery, textile machinery, food machinery, construction machinery, petroleum exploration, lamps, metal processing and other industries for round pipes, square pipes, oval pipes, triangular pipes, hexagonal pipes, diamond-shaped pipes, octagonal pipes and semi-circular pipes, etc.

Parameters of automatic laser tube cutting machine

Model | ST-FCT6000A/ST-FCT3000A |

Laser power | 1000W-20KW |

Laser wavelength | 1064nm |

Elector-optical conversion efficiency | 25%-30% |

Cutting thickness | 0.5-30mm (depend on the actual laser power) |

Cutting seam width | 0.1-1.3mm (depend on the actual thickness of metals) |

Repeated positioning accuracy of the machine tool | ±0.02mm/1000mm |

Positioning accuracy of the machine tool | ±0.03mm |

Max. idle moving speed | 100meter/min |

Max. acceleration | 1.2G |

Max. loading weight | 3000KG |

Single pipe Max. weight | 100KG (when air pressure is 6 bar, every meter≤16KG) |

Tailing length | ≥160mm |

Pipe processing range | 20mm≤Round pipe≤210mm, square pipe (20mm-150mm) |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 9000KG |

Machine dimension | 12000*2450*2400mm (L*W*H) |