Details Product Parameters Samples Video

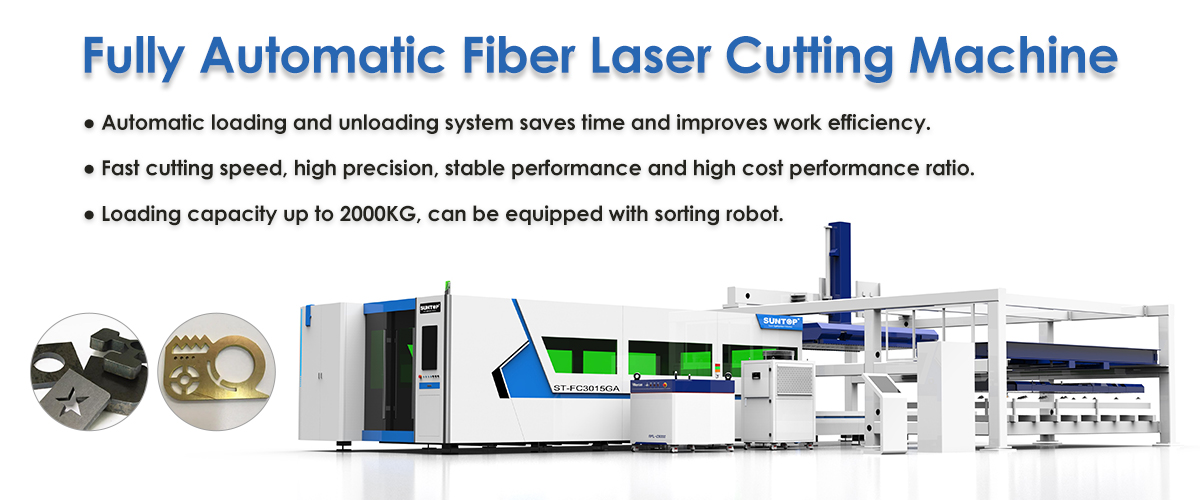

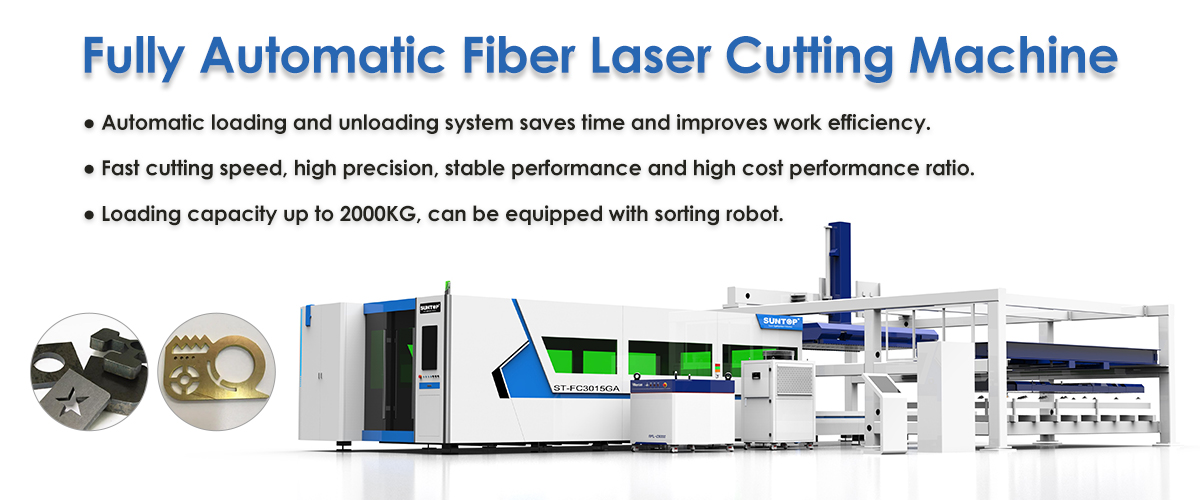

Features of automatic laser cutting machine

1. The machine adopts fully automatic sheet metal loading and unloading system, which can save labour and greatly improve cutting efficiency and productivity, it can load single plate sheet metal with weight up to 2000KG.

2. Suntop CNC fiber laser cutting machine mechanical transmission part has been tested and calibrated with USA brand laser interference for many times to ensure the our machine good and stable accuracy even after a few years of using.

3. Metal sheet separation function and automatic double sheet detection.

4. Equipped with self-developed off-line programming software, which greatly improves the ease and efficiency of operation.

5. Modular design, which can be customized according to customers' special requirements.

6. Vacuum suction cups are equipped with one-way shut-off valves to cater for feeding of different sizes and specifications of sheets.

7. Equipped with an air-conditioned room and a dust isolation/automatic tracking smoke extraction system, it is both energy efficient and has a perfect smoke extraction effect. The electrical components and laser generator are all inside the machine, which can keep the components working steadily, even 24 hours continuously, thus extending the life of the machine's optical components, electrical components, etc.

Details of automatic laser cutting machine

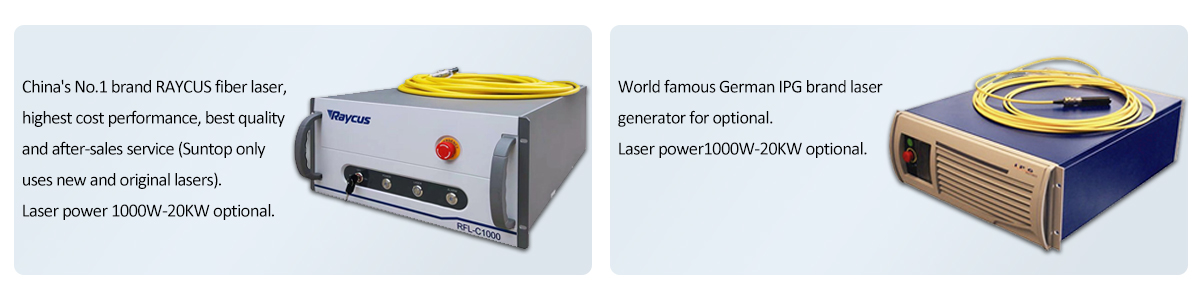

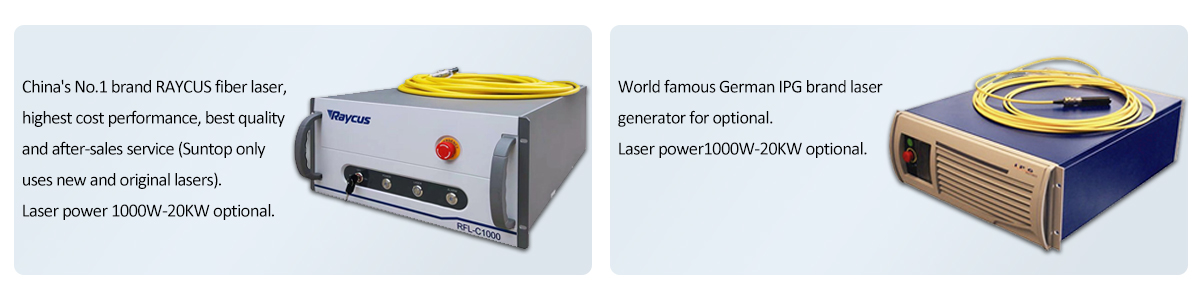

1. Fiber laser source

Famous brand Raycus, IPG, MAX fiber laser

The performance is stable, the service life can reach 100,000 hours, and the overall quality of the equipment is guaranteed.

Fiber laser sources produce superior beam quality, finer cut lines, higher productivity and better process quality. The fully enclosed constant temperature working environment makes the laser source more effective to ensure stable operation.

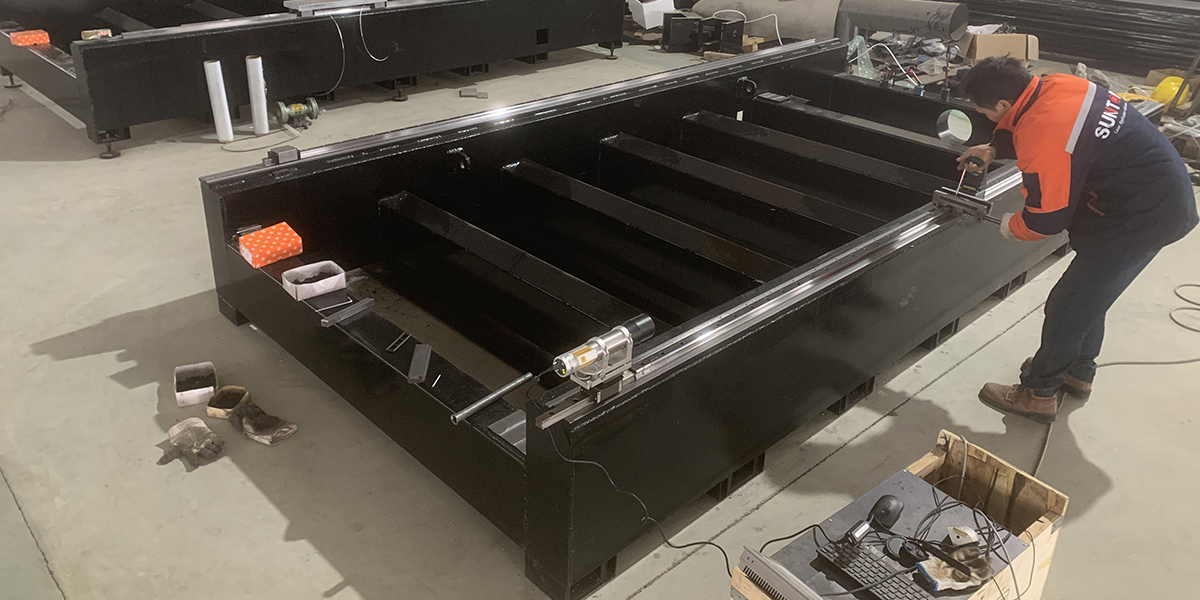

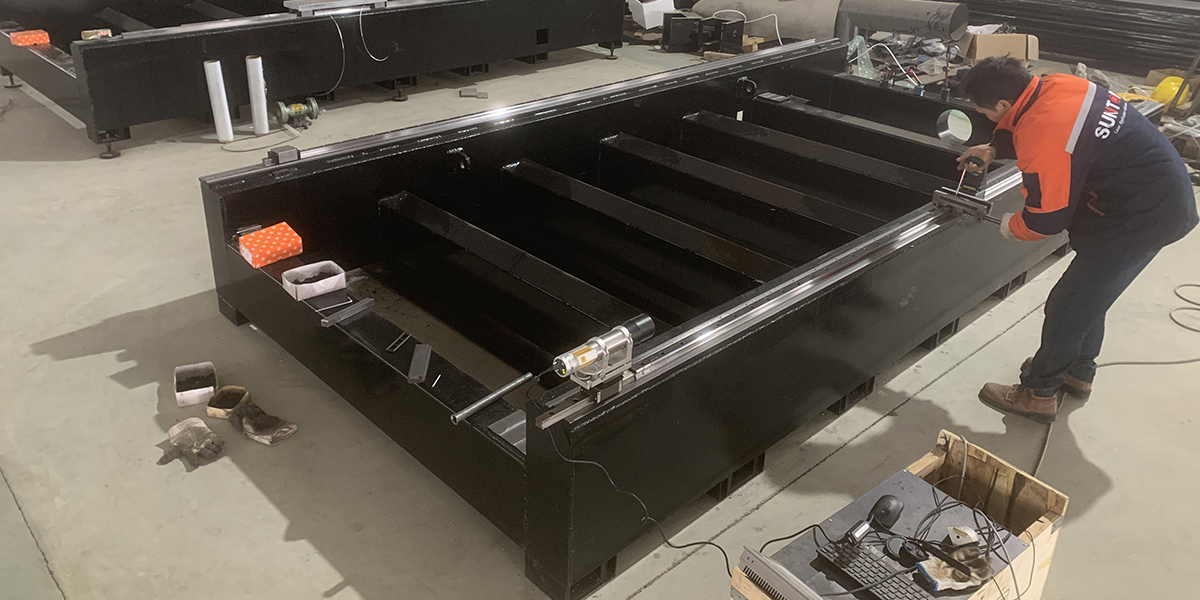

2. Heavy machine tool

Our machine tool is used integrated welding after annealing to eliminate stress, the process of cutting welding stress relief annealing—roughing—VSR—semi—finished—VSR—Finishing, a better solution due to welding and the stress arising from the processing, which greatly improve the stability of the machine, the common thickness range of structure metal profiles from 12-15mm which at least 20 years no deformation.

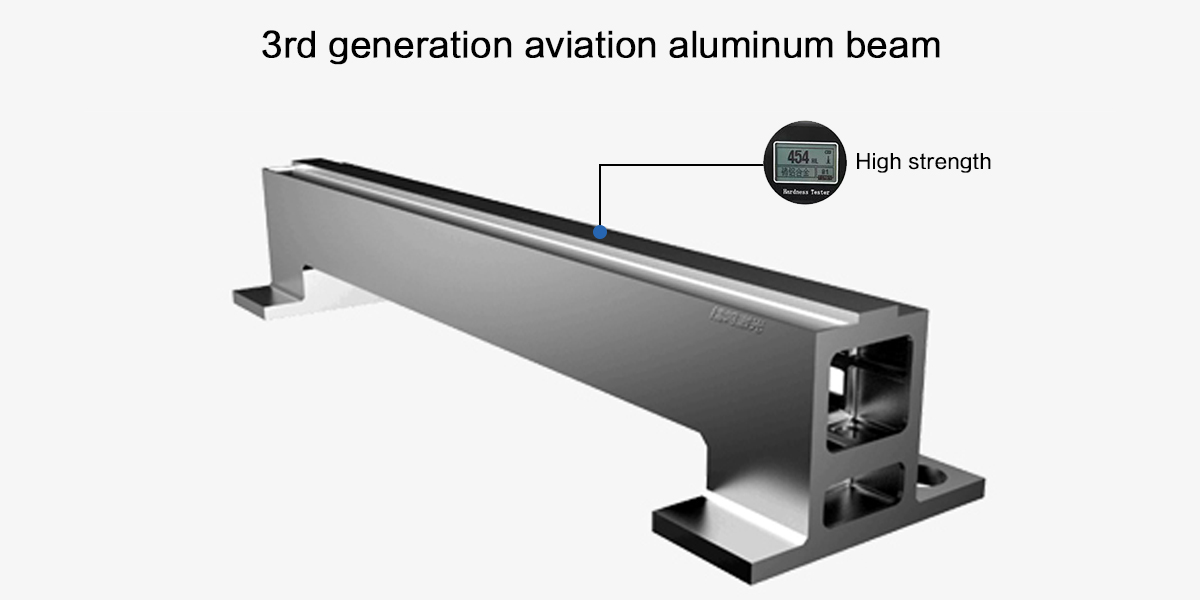

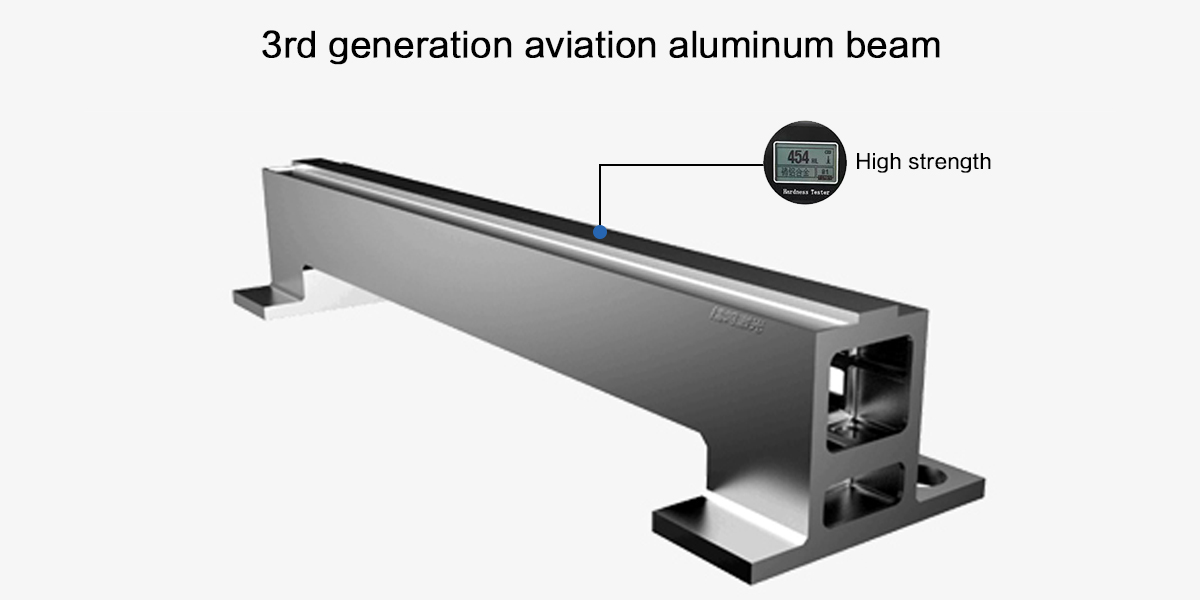

3. Cast aluminum beam

The overall cast aluminum beam, refined by artificial aging and solution treatment, so that the beam has excellent integrity, rigidity, and good toughness.

Light weight, anti-corrosion, anti-oxidation, low density, under the premise of meeting the precision, can realize all kinds of graphics fast cutting.

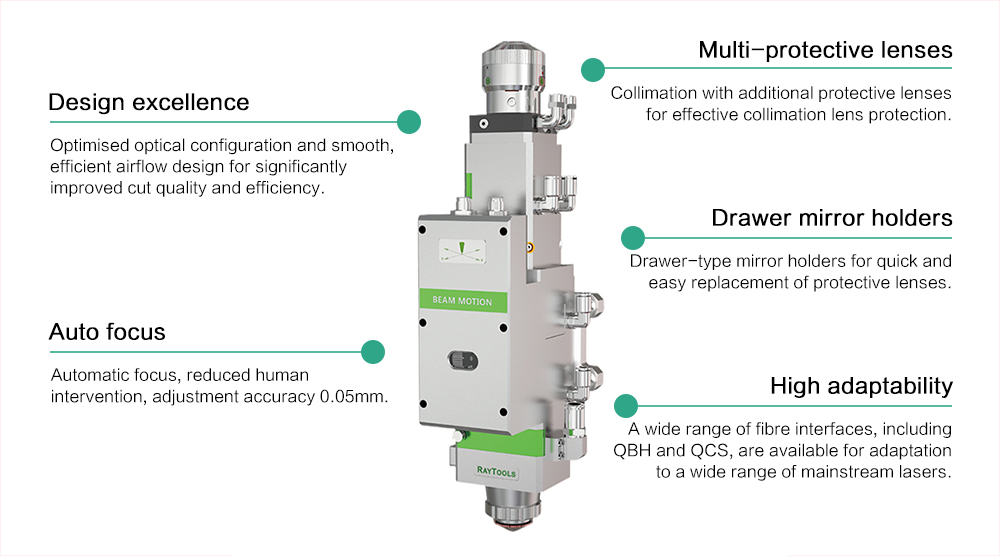

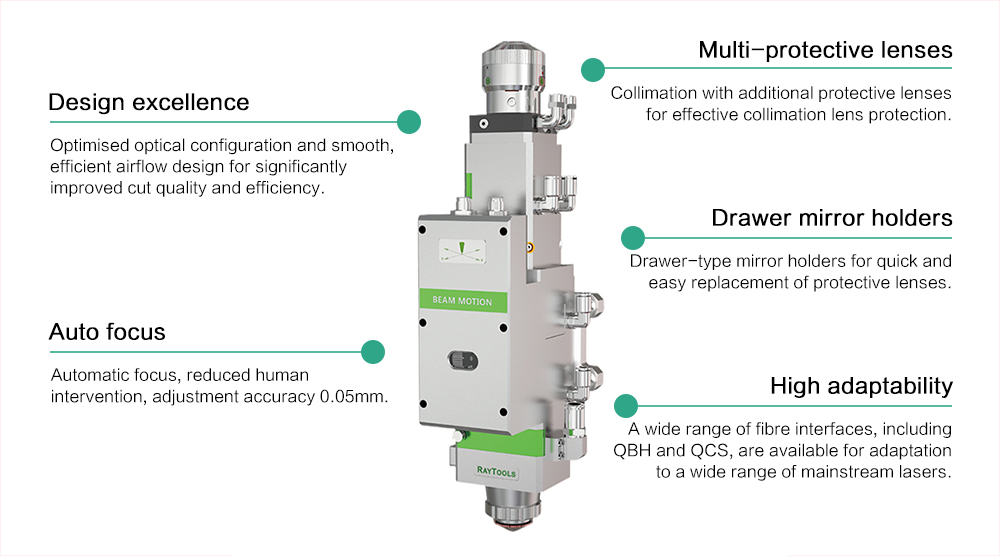

4. Autofocus laser cutting head

There is no need to manually focus, the software automatically adjusts the focusing lens to realize automatic perforation and cutting of plates with different thicknesses.

Both the collimating mirror and the focusing mirror are equipped with water-cooled heat sinks to reduce the temperature of the cutting head and increase the service life of the cutting head.

5. Independent Control Cabinet

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the lifespan of the electrical components.

The control cabinet is equipped with air conditioner for automatic constant temperature.This can prevent excessive temperature damage to components in summer.

6. PAD design display

The use of high-definition tempered glass makes the screen more delicate and smooth, and the operation is smoother.

7. Surveillance system

During the processing, each blind spot area can be monitored at any time, and the cutting process can be controlled; the high-definition intelligent monitoring system, remote alarm operation is no danger.

Advantages of automatic laser cutting machine

1. High and low double worktables, automatic loading and unloading, saving time.

2. Fully enclosed design, the observation window adopts European CE standard protective glass, the smoke and dust generated by cutting are filtered internally, and the emission meets the standard without pollution.

3. High cutting precision, fast speed, narrow cutting kerf, smooth and burr-free cutting surface, improving product quality.

4. Various cutting shapes, no mold, not affected by cutting shape.

5. Imported rack and pinion, guide rail, motor, higher stability.

6. High material utilization rate, one key for any piece of material is processing, programming forms the best material discharging mode, realizes the cutting of the net material, and improves the utilization rate of the plate.

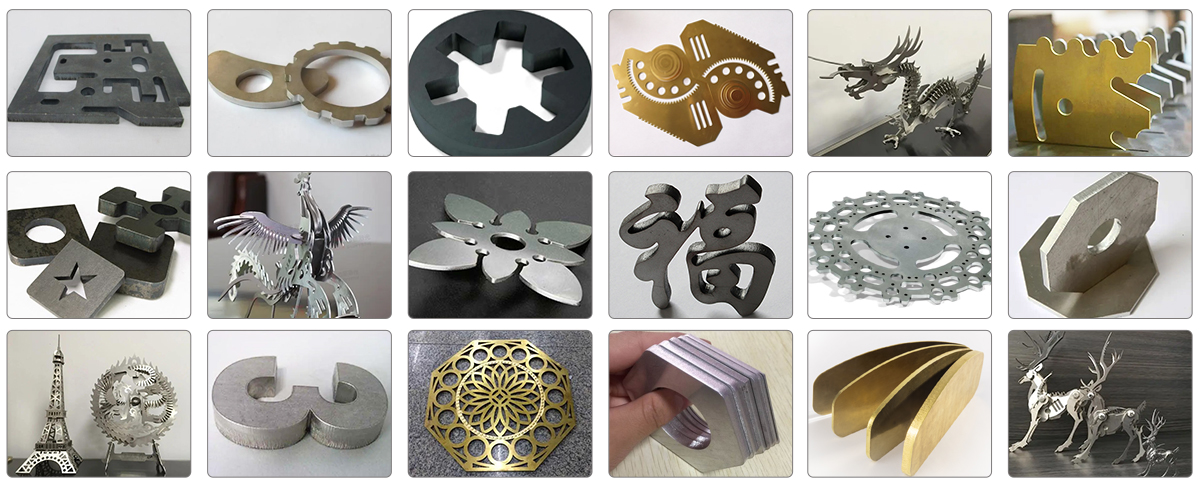

Automatic laser cutting machine application

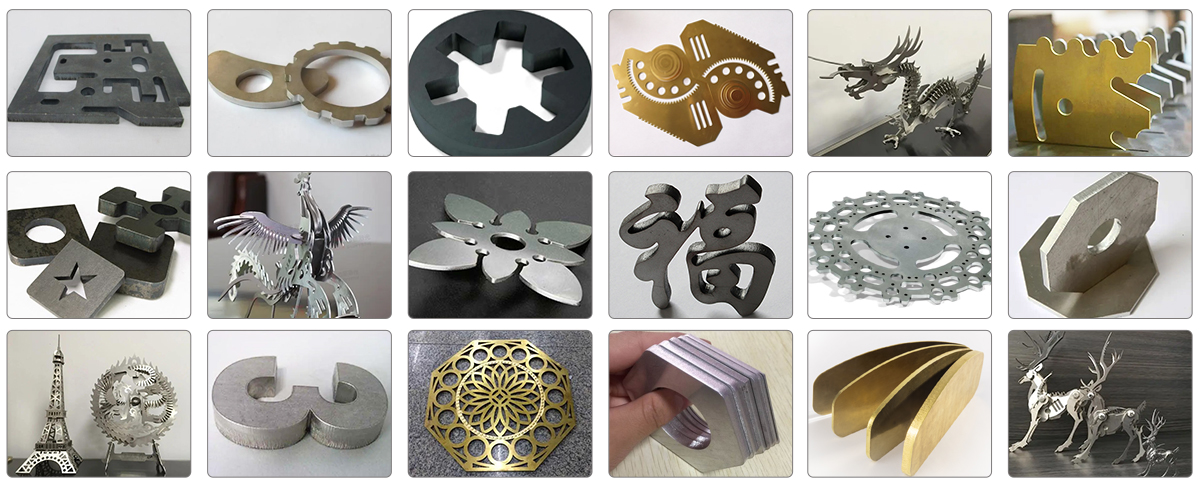

Application materials

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, pickle plate, alumina-plating, zinc plate, metallic copper, brass • and other kinds of metals.

Application industry

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

Parameters of automatic laser cutting machine

Model | ST-FC3015GA/ST-FC4020GA/ST-FC6020GA/ST-FC6015GA/ST-FC4015GA |

Laser power | 1000W-20KW |

Table Max. cutting size | 1500*3000mm (4000*2000mm, 6000*2000mm, 6000*1500mm, 4000*1500mm) |

Laser wavelength | 1064nm |

Transmission system | Gear+rails (we have standard brand; we can also produce as your requirements) |

Max cutting speed | 1--30m/min (according to metal material and laser power) |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (the exact data according to whick kind of metals and the corresponding thickness) |

Working environment | 0-45℃ ,Humidity ≤ 80%, non-condensing |

Voltage and frequency | Three phase 380V/50Hz or 60Hz |

Machine weight | 12500KG |

Machine dimension | 8850*3210*2100mm (L*W*H) |