|

Working principle of fiber laser marking machine

Fiber laser marking machines use the thermal effect of laser beams on the surfaces of different materials to achieve processing such as marking, scoring or cutting. The laser beam can cause the surface of the material to change to varying degrees by evaporation, melting or burning, thereby achieving the marking effect. This non-contact processing method has the characteristics of high precision, high efficiency and permanence, and is widely used in industrial production, packaging, electronics, medical and other fields. By controlling the parameters of the laser beam such as power, focus and scanning speed, various forms of marking can be achieved, including patterns, text, barcodes, etc.

|

Advantages of fiber laser marking machine

● High precision: The fiber laser marking machine is equipped with high-quality optical lens groups and precision control systems, which can achieve high-precision marking and scoring at the micron level, and is suitable for fields with high requirements for fine processing.

● High speed: The fiber laser marking machine has fast marking and cutting functions, fast processing speed, high production efficiency, and is suitable for mass production.

● High efficiency: Laser processing does not require contact with the surface of the workpiece, there is no problem of mechanical tool wear and tool change, high work efficiency, and can reduce production costs.

● High stability: The fiber laser marking machine uses a stable and reliable fiber laser as the laser source, with good beam quality, high stability, and the ability to work continuously for a long time.

● High adaptability: The fiber laser marking machine is suitable for marking and processing of a variety of materials, including metals, plastics, ceramics, glass and other materials, and has a wide range of applications.

● Environmental protection and energy saving: The laser marking process does not require the use of chemical agents, does not produce waste gas, wastewater and waste residue, meets environmental protection standards, and saves energy and reduces emissions.

● Easy operation: The fiber laser marking machine has a friendly operation interface and is easy to operate. Different marking effects and patterns can be achieved through software control, which is suitable for various user operations.

|

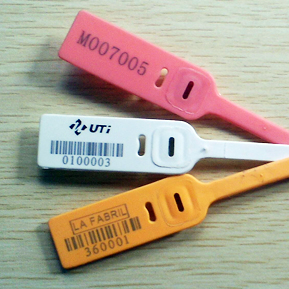

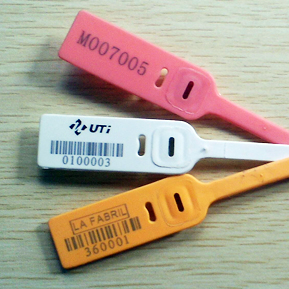

Industry applications of fiber laser marking machines

Electronic industry

Used for marking, scoring and cutting of electronic components, electronic product housings, circuit boards, mobile phone cases, electronic tags, etc.

Automotive parts industry

Used for marking, scoring, parts traceability codes, anti-counterfeiting labels and parts processing on automotive parts.

Metal processing industry

Used for etching, marking, cutting and engraving of metal products, stainless steel, aluminum alloy, copper and other metal materials.

Medical device industry

Used for marking QR codes, logos, production dates and other information on medical devices and medical equipment.

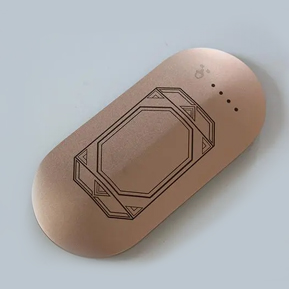

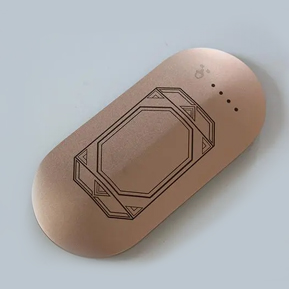

Jewelry industry

Used for brand marks, serial numbers, LOGO and other engraving on valuable items such as jewelry, watches, glasses frames.

Plastic products industry

Used for marking, cutting and engraving of materials such as plastic products and PVC products.

Industrial manufacturing industry

Used for marking, QR code identification, production batches, parameter marking, anti-counterfeiting identification and other applications on workpiece surfaces.

|

Application materials of fiber laser marking machine

It is suitable for working with most metal marking applications such as Gold, Silver, Stainless Steel, Brass, Aluminum, Steel, Iron Titanium etc., and can also mark on many nonmetal materials, such as ABS, Nylon, PES, PVC etc.