In our daily life, we can often see the production date, two-dimensional code, traceability code and other marks on household goods, food packaging and so on. If we look carefully, we can see that some traces are very rough, some even appear to be fuzzy and incomplete, generally sprayed with ink. Some traces are particularly delicate and clear, it is difficult to erase, this is a laser marking machine.

Laser marking machine principle

Laser marking is a laser beam on the surface of various substances for permanent marking. The role of marking is through the surface layer of material evaporation to expose the deep material, or through the light energy caused by the surface layer of material chemical and physical changes to "carve" traces, or through the light energy to burn off some substances, showing the pattern and text to be etched.

Advantages of laser marking

1. Wide range of marking: a variety of metal, non-metallic materials can be processed. Especially for high hardness, high melting point, brittle materials for marking more advantages.

2. Speed: laser marking is more than 100 times faster than ordinary marking methods, and can ensure the accuracy of repeated marking.

3. High quality: non-contact processing, no damage to the product, no tool wear, good marking quality. Can realize fine marking, clean and pollution-free. The marking material is affected by oxidation, deformation and thermal expansion of the area is relatively small.

4. Less energy consumption: the laser beam is fine, the processing material consumption is very small, the processing heat-affected zone is small.

5. High degree of automation: high processing efficiency, the use of computer control, easy to realize automation.

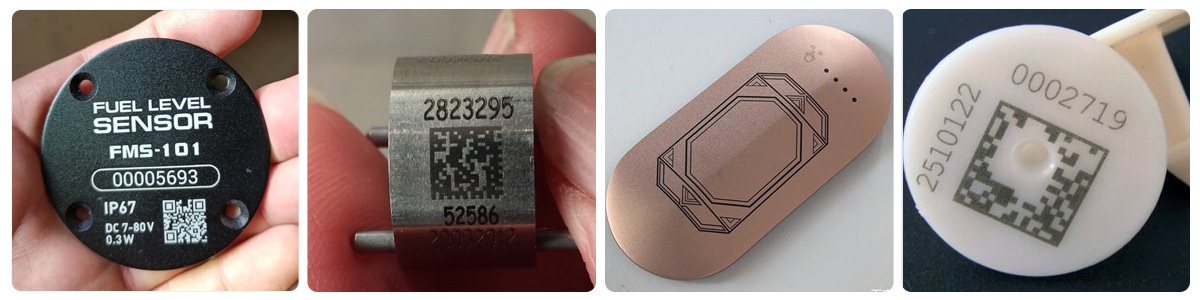

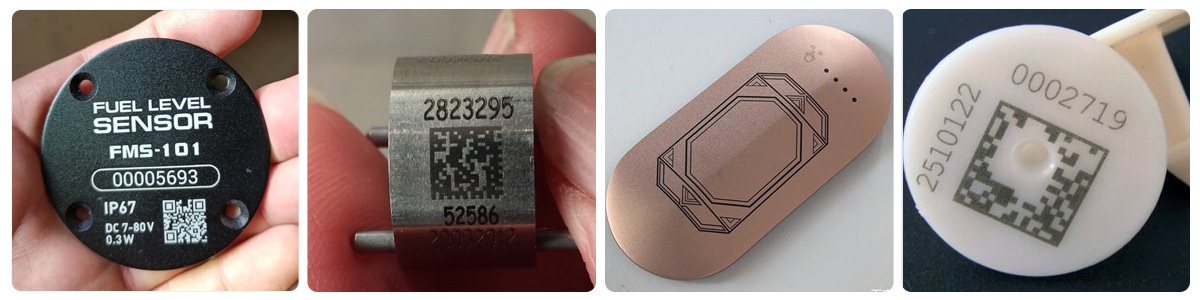

Application range of laser marking machine

● Fiber laser marking machine

Material: suitable for stainless steel, carbon steel, aluminum, iron, copper, gold, silver, platinum, titanium and other metal materials and ABS, nylon, PVC and other parts of the plastic marking.

Industry: widely used in integrated circuit chips, computer parts, industrial bearings, clocks and watches, electronic and communication products, aerospace devices, a variety of automotive parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco, and military affairs, and many other areas of graphic and text marking, as well as high-volume production line operations.

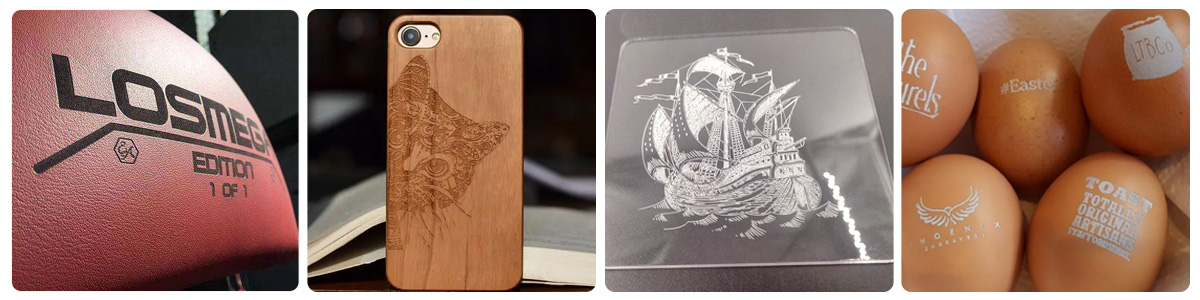

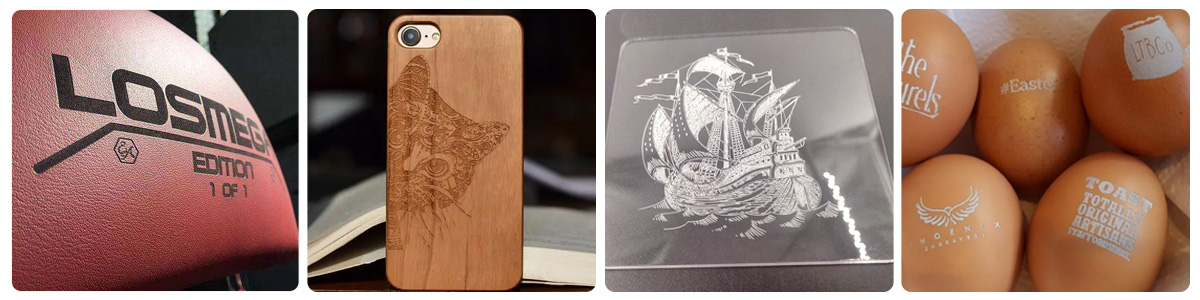

● CO2 laser marking machine

Material: mainly applied to non-metallic materials, such as bamboo products, wood, paper, PPC, PVC, epoxy resin, acrylic, leather, glass, construction ceramics, rubber, etc.

Industry: widely used in pharmaceutical packaging, food packaging, beverage packaging, plastics, textiles, leather garments, handicrafts, electronic components, communications, clocks and watches, eyeglasses, printing plates, non-metallic nameplates, labels and so on. and other industries.

● UV laser marking machine

Material: very wide range of types, including metal, non-metal, plastic, glass, ceramics and other materials. Among them, metal materials include stainless steel, aluminum alloy, copper, iron, titanium, etc.; non-metallic materials include plastics, rubber, ceramics, glass, wood, leather and so on.

Industry: Suitable for high-end market, surface marking of packaging bottles of cosmetics, medicines, videos and other polymer materials, surface marking of glass, polymer materials and other objects, micro-hole processing, flexible PCB board, LCD, TFT marking and scratching Sheet cutting, LCD glass QR code marking, glassware surface drilling, metal surface coating marking, plastic buttons, electronic components, communication equipment, building materials, etc.