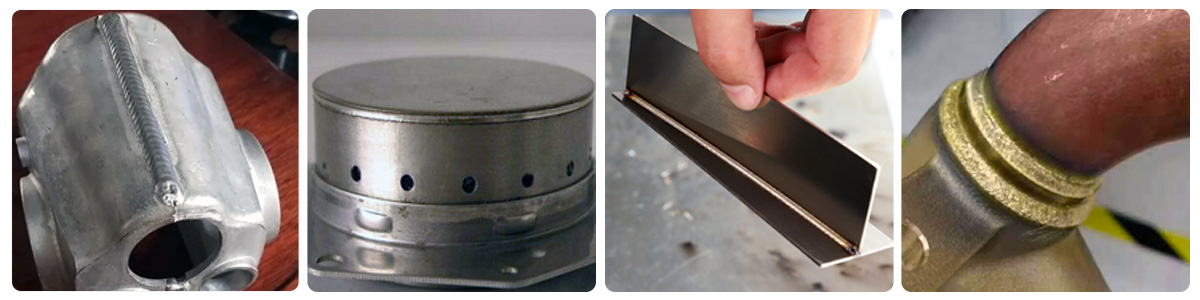

Laser welding technology plays an increasingly important role in aluminum welding, especially for some common problems in aluminum alloy welding. Here are some key aspects of how laser welding solves aluminum welding problems:

1. High energy density

Laser welding uses a high-energy-density laser beam to focus on the welding area, which can quickly heat and melt the aluminum material. This high energy density can complete the welding process in a very short time, reduce heat input, and thus control the generation of thermal deformation and welding residual stress to a limited extent.

2. Small heat-affected zone

The heat-affected zone (HAZ) produced by laser welding is relatively small, which helps to reduce the thermal impact of surrounding materials and avoid microstructural changes caused by temperature changes, thereby reducing the risk of cold cracks in aluminum alloy welding. This is a major advantage in aluminum welding, especially when welding thin materials.

3. Accurate process control

Laser welding systems are usually equipped with advanced control and monitoring technologies, which can accurately adjust welding parameters such as laser power, welding speed, focus position, etc. Through real-time monitoring, the stability and repeatability of the welding process can be ensured, significantly improving the welding quality.

4. Fewer welding defects

During the laser welding process, the formation of the weld is relatively stable, and the probability of welding defects such as pores and inclusions is greatly reduced. This is because laser welding can better control the formation of the molten pool, reduce the risk of gas capture during solidification, and effectively remove pollutants such as oxide films.

5. Adapt to multiple welding positions

The high integration and flexibility of laser welding enable it to perform efficient welding in a variety of welding positions (such as horizontal, vertical and inclined). This feature gives laser welding a greater advantage when dealing with complex structures and difficult-to-access locations.

6. Can be combined with other technologies

Laser welding can be combined with other welding technologies (such as MIG/MAG welding, electron beam welding, etc.) to form a composite welding process. For example, preheating before laser welding or applying traditional welding processes in subsequent processing can enhance the quality of the weld and the strength of the overall structure.

7. Automation and digitalization

Laser welding equipment can be easily integrated into automated production lines to achieve high-speed, high-precision automatic welding. This automation capability not only improves production efficiency, but also reduces errors caused by human operation and improves the consistency and repeatability of welding.

Laser welding technology effectively solves the common problems in aluminum welding through its high energy density, small heat-affected zone, precise process control and low defect rate. While improving welding quality, laser welding can also improve production efficiency, reduce costs, and promote the application of aluminum materials in aviation, automobiles and high-end manufacturing. Click here for more information