Details Product Parameters Samples Video

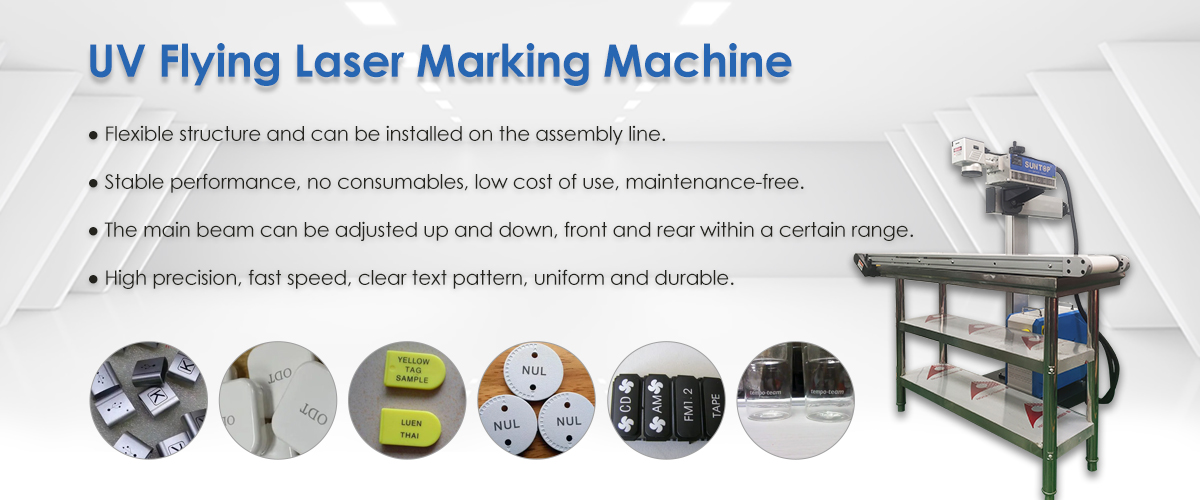

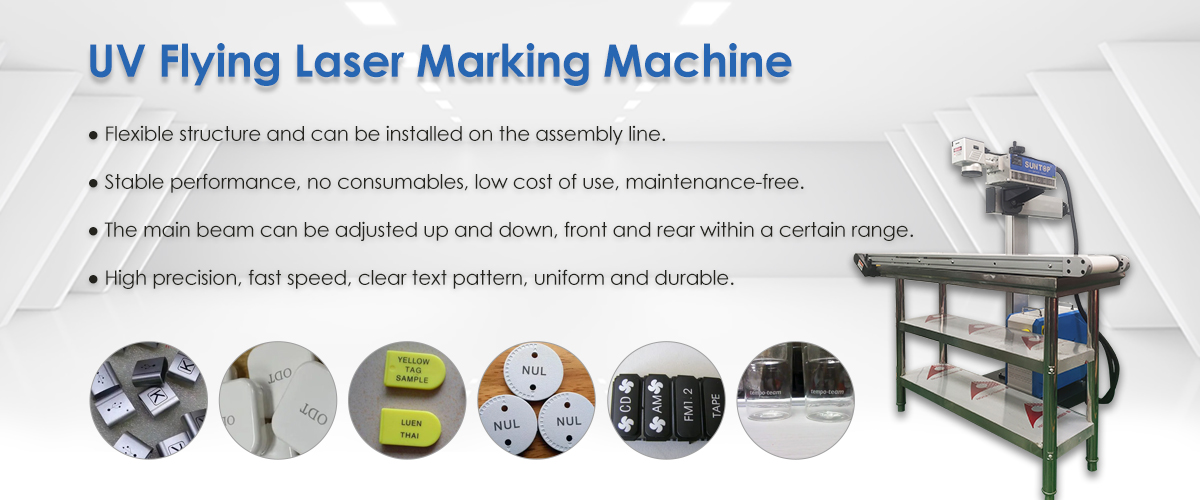

Features of uv laser marking plastic

1. The structure of the whole machine is flexible and occupies a small area.

2. Specially designed for high-speed production lines, it can be installed flexibly and used in conjunction with production lines.

3. Intelligent touch screen control system, no need for computer, easy to use.

4. Adopt the industry's most compact laser marking head to achieve simple integration, reduce installation costs and improve positioning flexibility.

5. Compatible with a variety of focusing lenses, and can adjust a variety of light output directions to meet the needs of different application scenarios.

6. The stable and light main beam lifting mechanism can adjust the main beam up and down, forward and backward within a certain range.

Details of uv laser marking plastic

1. Laser source

Adopt famous brand laser, stable light output, fine spot, strong focusing effect.

2. UV 355nm field lens

High-precision UV 355nm field mirror = 160mm / F = 210mm / F = 254mm Optional high-speed, high-precision scanning head.

3. Rotate the manual switch

The laser path can be rotated 180°, and the optical path can move back and forth, with scale indication.

4. Control panel

BJJCZ brand original EZCAD control system has the characteristics of high stability, easy operation and good performance.

5. Touch screen industrial control all-in-one machine

Touch screen experience, running without lag, and has a high anti-magnetic, dustproof, impact resistance and strong anti-interference ability, can work continuously for a long time.

6. Flying marking system

Based on the development of flying marking, it can edit any document pattern, etc. very easily, and can automatically produce batch number and running number, and the software parameters can be modified flexibly.

Advantages of uv laser marking plastic

1. The beam quality is good, the focus spot is extremely small, and special material marking can be carried out to achieve ultra-fine marking.

2. The heating area is small, so it is not easy to produce thermal reaction and the problem of material scorching.

3. High processing efficiency, computer control, easy to realize automation

4. Non-contact processing, no damage to products, no tool wear, good marking quality.

5. The marking quality is good, the message is clear and permanent, no fading or falling off.

6. Wide range of materials suitable for processing, especially suitable for the high-end market of ultra-fine processing.

UV laser marking plastic application

Application materials

It is suitable for almost all materials. Widely used in metal (all metals such as iron, copper, aluminum, magnesium, zinc, etc.), glass, crystal, PCB, plastic, fiber, paper, paint, silicon wafer, LCD, polyamide, wire, plug and other polymer materials.

Application industry

Widely used in integrated circuit chips, computer accessories, industrial bearings, clocks, electronics and communication products, aerospace devices, various auto parts, home appliances, hardware tools, molds, wires and cables, food packaging, jewelry, tobacco and military, automotive Accessories, hydraulic pump valves, hardware tools, mold processing. Petroleum pipe fittings, hardware products, integrated circuits, IT electronic products, instrumentation, precision instruments, medical equipment, tobacco industry, pharmaceutical industry, food industry, aerospace, military electronics, craft gifts and many other metal and non-metal fields and mass production lines Operation.

Parameters of UV flying laser marking machine

Model | ST-UV03F | ST-UV05F | ST-UV08F |

Laser Power | 3W | 5W | 8W |

Max. marking range | 110*110mm | 150*150mm | 180*180mm |

Output power | >3W@30KHZ | >5W@40KHZ | >8W@40KHZ |

Maximum pulse energy | 0.1MJ@30KHZ | 0.12MJ@40KHZ | 0.14MJ@40KHZ |

Pulse duration | <15NS@30KHZ | <18NS@40KHZ | <21NS@40KHZ |

1/e2 beam diameter at output | 0.7mm | 0.8mm | 0.9mm |

Laser Type | UV laser |

Laser source | GAIN(JPT and other brand optional) |

Control Software | EZCAD |

Cooling Mode | Air Cooling |

Beam diameter | ≤ 10mm |

Working Accuracy | ±0.002MM |

Marking Speed | 1-12000mm/s |

Repetition Frequency | 20-100KHz |

Laser Wavelength | 355nm |

Minimum Font for Marking | 0.01mm |

Working Voltage | 220V+10% 50/60 Hz |

Graphic Format Supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Applicable Material | all metal material and all non metal material |

Spare Parts Come with the Machine | Protective glasses, Metal business card, Foot switch, Hex socket wrench, Power cord |

Optional Accessories to Purchase | D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

Net Weight (KG)/ Gross Weight | 150KG / 180KG |

Machine size | 510*660*1470mm (L*W*H) |