Details Product Parameters Samples Video

Features of ss laser cutter

● High-power machine with hollow structure effectively reduces the heating area in the laser cutting process. The machine tool will not be deformed in long-term use, which also ensures good cutting precision and greatly improves the stability of the machine. It will not be deformed for at least 20 years of use.

● Imported high-precision dual servo drive and guideway transmission, HlWIN linear guide, smooth drive and high precision.

● X and Y axes are equipped with Japanese servo motors with high precision, high speed, large torque, large inertia and stable performance, which ensures the high speed and acceleration of the whole machine.

● The mechanical transmission part has been tested and calibrated by laser interferometer for many times to ensure that the machine can still maintain good and stable precision after several years of use, which is very important for the end users.

● The new generation of intelligent anti-shaking function automatically adjusts the sensing sensitivity according to the degree of sheet shaking, realizing stable cutting and improving processing efficiency.

● Automatic edge finding, automatic processing and automatic exchange. Realize the perfect combination of man and machine, greatly improve the production efficiency.

● Automatic lubrication of the guide rails of each axis to ensure the long-term stable operation of the equipment.

Details of ss laser cutter

1. Fiber laser source

Adopt famous brand Raycus, IPG, MAX fiber laser. The performance is stable, and the service life can reach 100,000 hours, which ensures the overall quality of the equipment.

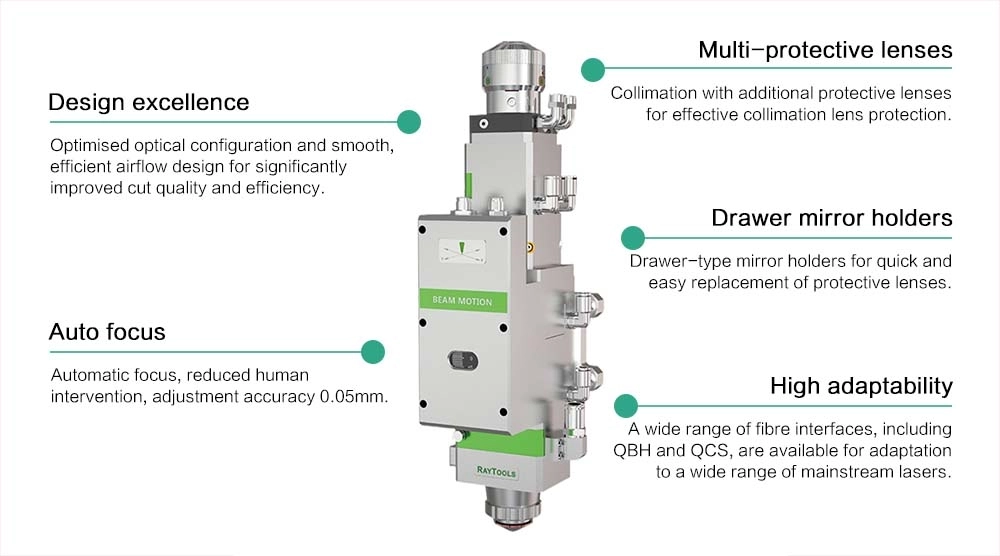

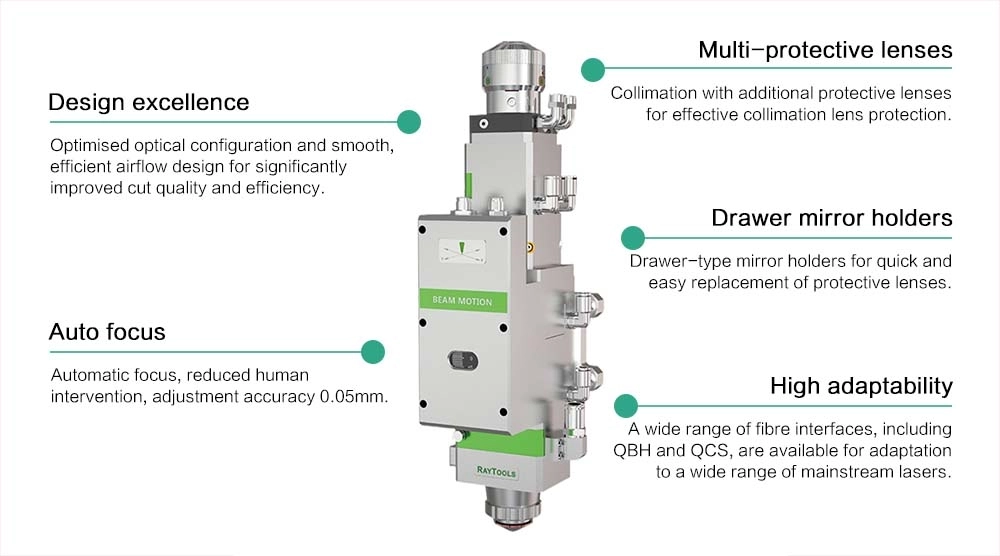

2. Auto focus laser cutting head

◆ Without manual focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

◆ Bigger adjustment range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

◆ Long service life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

3. Advantages of machine tools

● We use a high-power machine tool with a hollow structure, which effectively reduces the heating area during the laser cutting process. The machine tool will not be deformed after long-term use, and it also ensures good cutting accuracy and greatly improves the stability of the machine. At least use 20 years will not deform.

● Our machine tools are welded with thick steel plates, and the weight of one machine tool alone reaches 4 tons.

4. Core technology:

◆ The optical path system of the laser is stable. After thousands of vibration experiments, the optical path system of the laser is stable;

◆ Mechanical follow-up cutting head, purely mechanical transmission, stable and anti-interference.

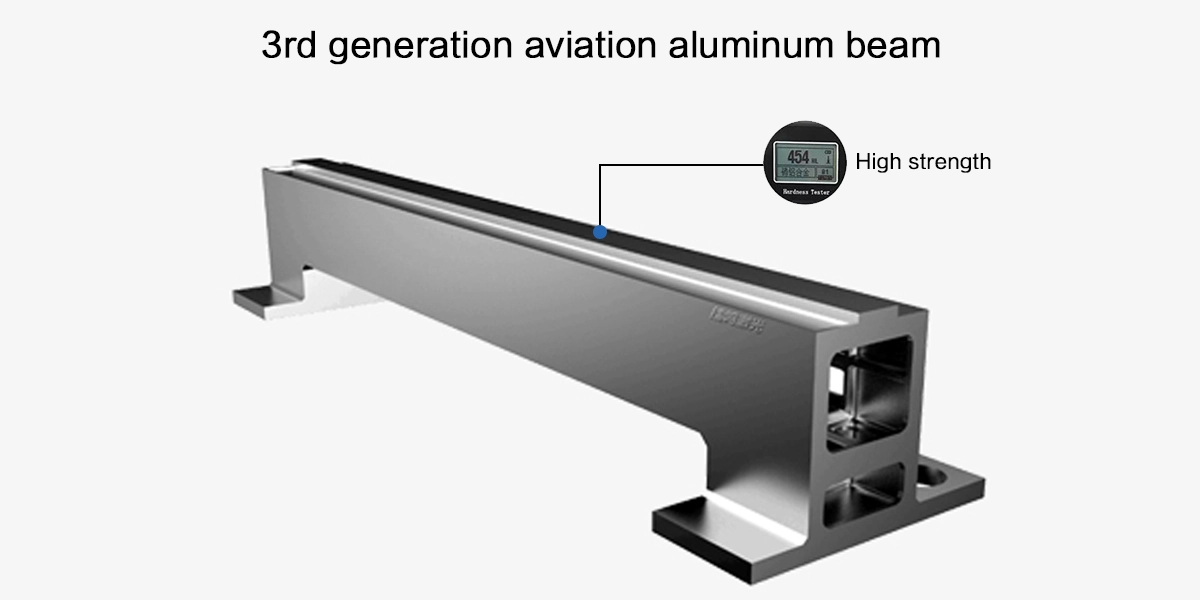

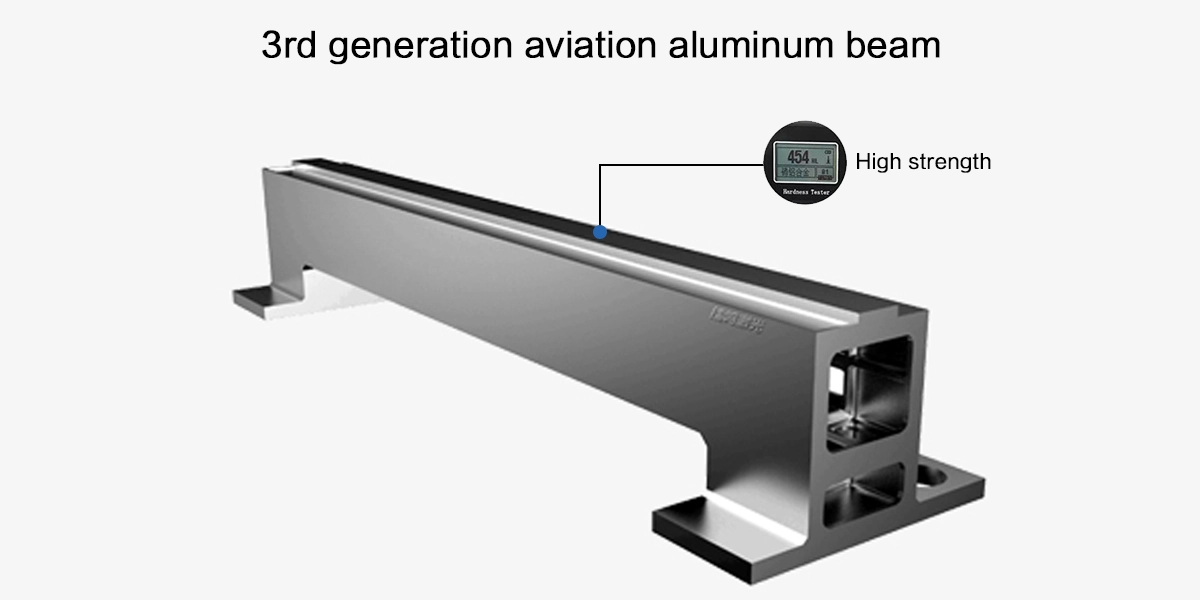

5. Aviation cast aluminum beams

The overall cast aluminum beam is refined by artificial aging and solid solution treatment, so that the beam body has excellent integrity, rigidity, and good toughness.

Light weight, anti-corrosion, anti-oxidation, low density, under the premise of satisfying the precision, it can realize the rapid cutting of various graphics.

6. Independent control cabinet

All electrical components and laser sources are built in an independent control cabinet, with dust-proof design, which prolongs the service life of electrical components.

The control cabinet is equipped with an air conditioner, which can automatically maintain the temperature. This can prevent damage to the components due to excessive summer temperatures.

7. Surveillance system

During the processing, each blind spot area can be monitored at any time to control the cutting process; high-definition intelligent monitoring system, remote alarm operation without danger.

Advantages of ss laser cutter

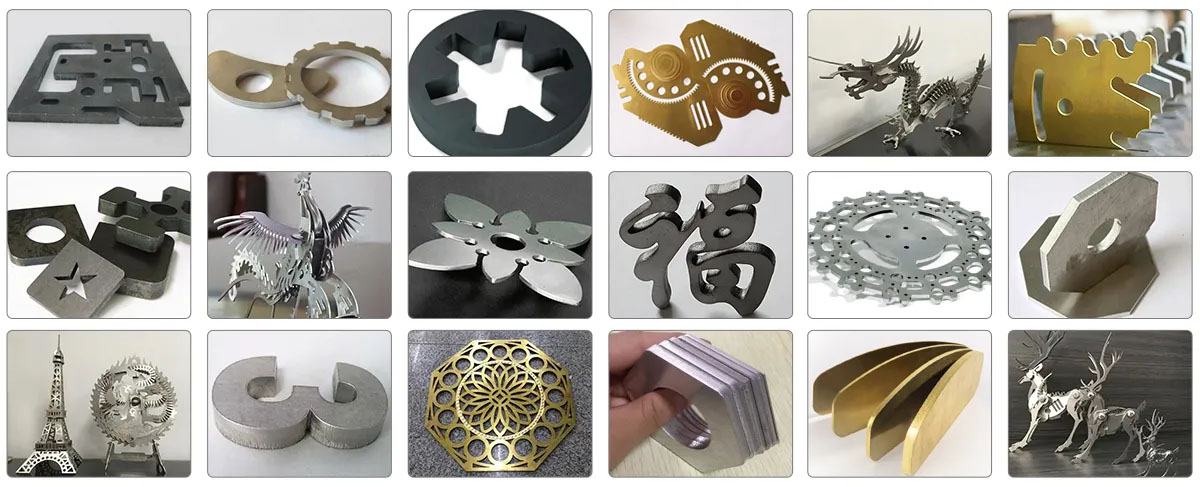

Processing advantages of ss laser cutter

● High accuracy, high speed, narrow cutting slit, minimized heat-affected zone, smooth and burr-free cutting surface.

● The laser cutting head does not come into contact with the material surface and does not scratch the workpiece.

● Narrowest cutting slit, smallest heat-affected zone, minimal localized deformation of the workpiece, no mechanical deformation.

● Good processing flexibility, can process arbitrary graphics, can also cut pipes and other profiles.

● It can cut steel plate, stainless steel, aluminum alloy plate, hard alloy and other materials of any hardness without deformation.

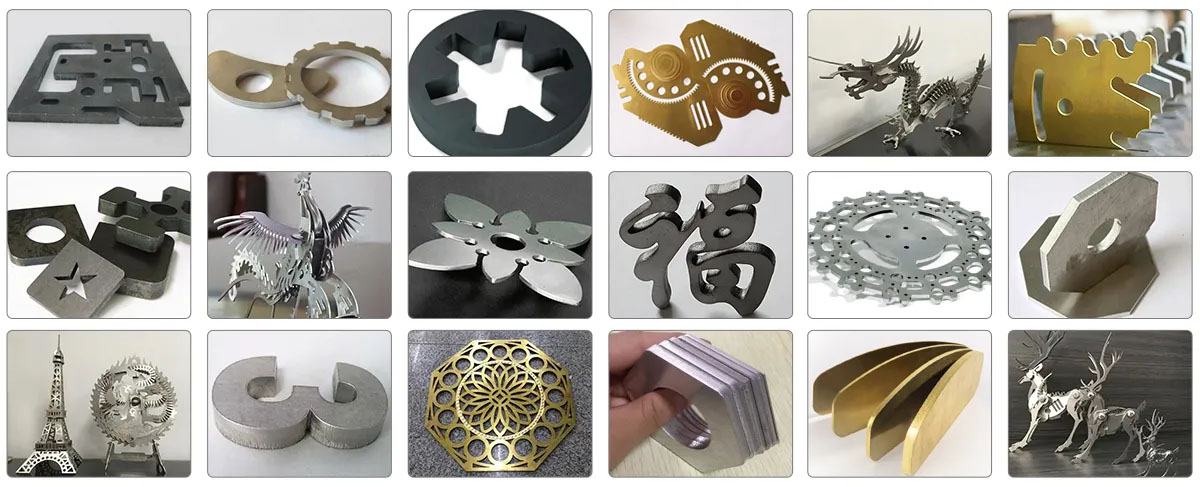

Application materials of ss laser cutter

It can be used to cut various metal materials such as carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, galvanized sheet, etc.

Application industry of ss laser cutter

Sheet metal processing, advertising signs production, high and low voltage electrical cabinet production, mechanical parts kitchen utensils, automobile, machinery, metal products, saw blades, electrical parts, optical industry, spring, board, kettle, medical microelectronics, hardware, knife measuring tools and other metal processing industrial.

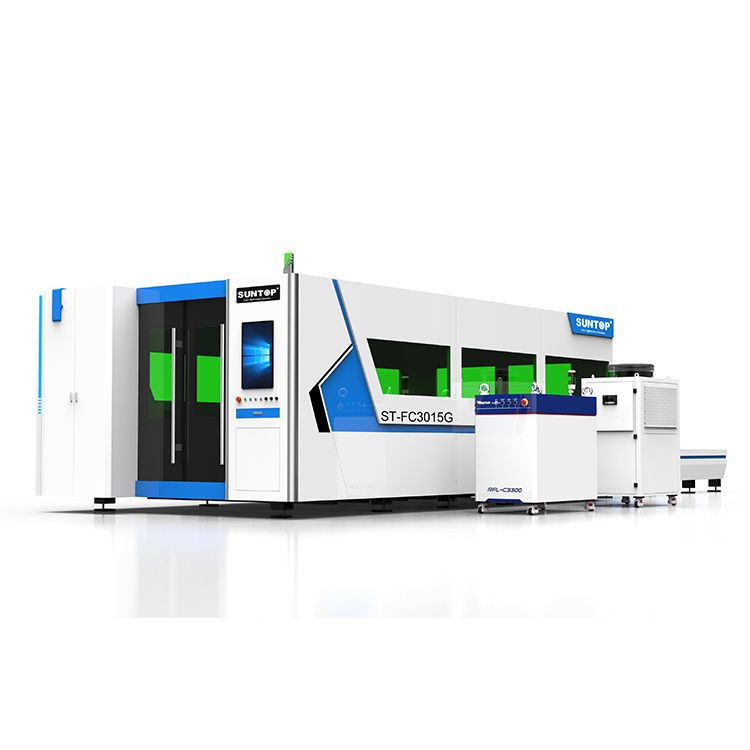

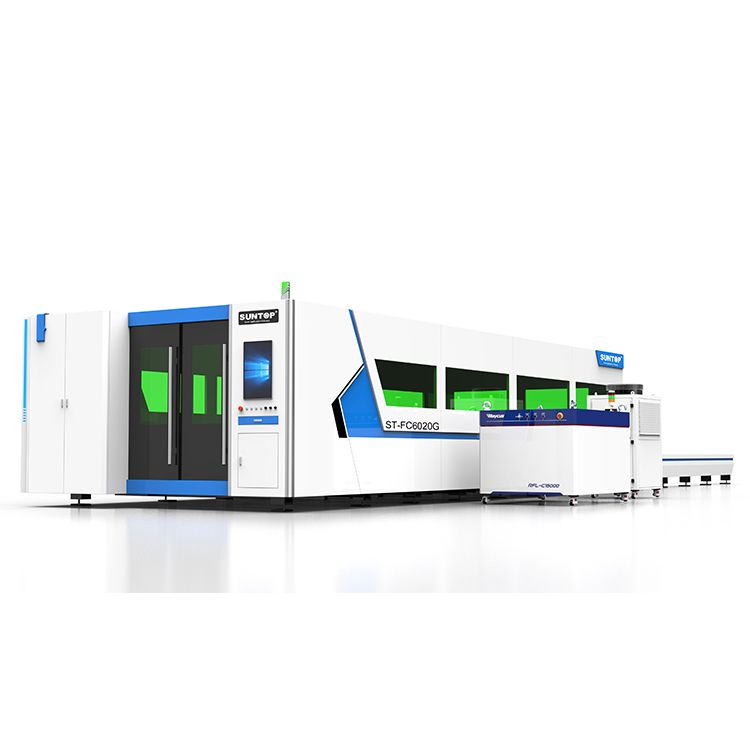

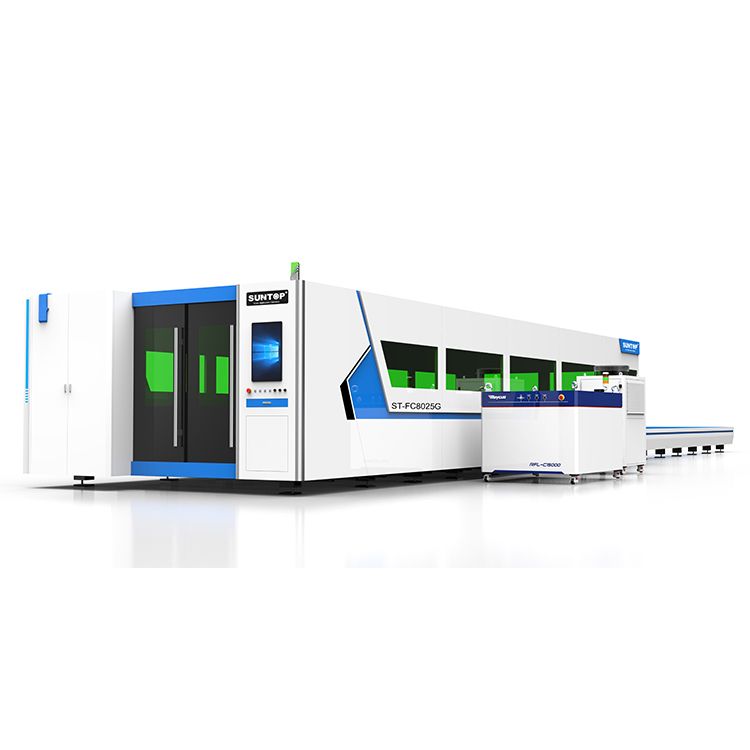

Parameters of ss laser cutter

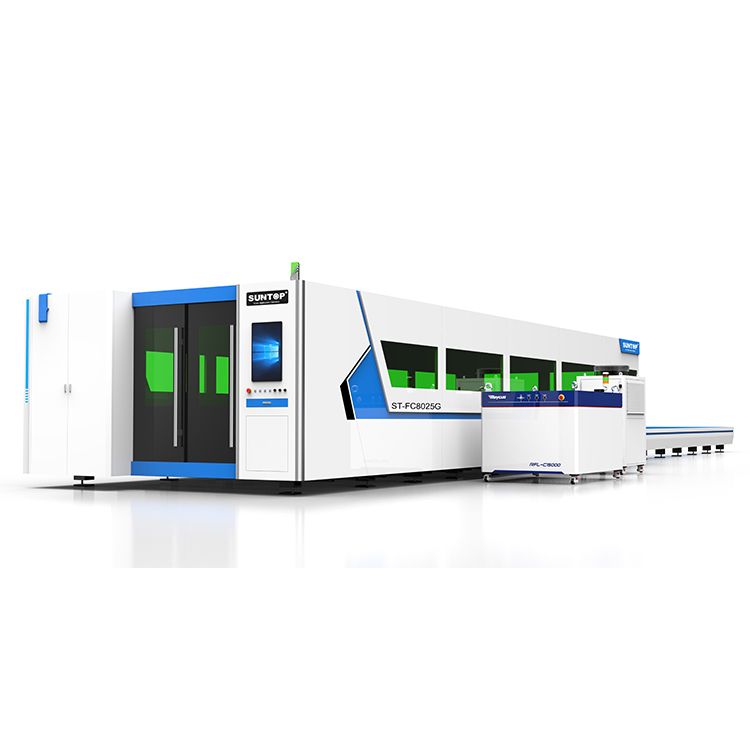

Model | ST-FC3015G/4020G/1560G/6020G/6025G |

Table Max. cutting size | 1500*3000/4000*2000/1500*6000/2000*6000/2500*6000mm |

Laser power | 1500W-20KW |

Transmission system | Double rack & pinion and servo drive |

Transmission | High precision screw guide transmission |

Laser wave length | 1064nm |

Laser source | Raycus Brand (MAX, IPG can be choose) |

Maximum speed | 120m/min |

X.Y axis location accuracy | ±0.01mm |

X.Y axis repeat location accuracy | ±0.01mm |

X.Y axis max moving speed | 30m/min (also according to kind of materials and thickness) |

Cooling mode | Water Cooling |

Maximum acceleration | 1.5G |

Equipment power | 8KW (not include laser generator and chiller) |

Working environment | 0-45℃, Humidity ≤ 80%, non-condensing |

Graphic format supported | AI, PLT, DXF, BMP, DST, DWG, DXP |

Working voltage | 380V±10%, 50-60HZ |

Machine weight | 8500KG |

Machine dimension (L*W*H) | 8850*3210*2100mm |

Quality assurance

1.. Every production process has a special person to test to ensure quality

2. Have professional engineers to check the quality

3. All products have passed CE, FDA, ISO9001 and other certifications

4. Suntop Laser Cutting Machines is subjected to strict tests and continuous 24-hour laser beam output before leaving our factory to ensure 100% machine stability