Details Product Parameters Samples Video

Featres of optical fiber laser welding machine

1. Four functions in one machine: quick switching between cleaning, welding, cutting and weld cleaning modes.

2. Integrated design, reasonable structure, dustproof, good heat dissipation, effectively extending the service life of machine parts.

3. The independently developed swing welding head is small, lightweight, easy to operate and flexible.

4. It has the dual protection function of water path and air path (patented technology), which effectively avoids damage to the laser lens or optical components caused by operator misoperation, thus greatly reducing the machine failure rate and effectively extending the machine's service life. The life of consumables.

5. It has multiple safety alarm functions. The trigger switch of the welding copper nozzle is only effective when it touches the metal and the safety clip clamps the metal plate. The welding copper nozzle will automatically lock when the workpiece is removed. The machine's high safety ensures the absolute safety of the operator during work.

6. Use infrared positioning to verify the position of the welding head during the welding process. The welding position is more accurate, the welding seam is smooth and beautiful, and it is easy to grind and polish. No post-welding treatment is required or only simple processing is required.

Details of optical fiber laser welding machine

1. Laser welding head

Lightweight, only 0.8KG, flexible and convenient for welding metal parts of any shape, adjustable weld width, capable of long-distance welding up to 10 meters. Equipped with a safety temperature monitoring system.

2. Operation interface

Multilingual intelligent control panel, flexible adjustment of welding parameters, multiple sets of welding parameter libraries, cumulative timing of light output, etc.

3. Automatic wire feeding system

Touch screen design, automatic wire filling, fully digital design, supports stainless steel and aluminum wires with diameters of 0.8mm, 1.0mm, 1.2mm, 1.6mm, and 2.0mm.

4. Laser source

We use custom-made fiber with a minimum core diameter of 20um, which has deeper penetration depth and a laser lifespan of up to 100,000 hours. It is maintenance-free and has Bluetooth functionality.

5. Chiller

Dual-cycle water cooling system provides better cooling for the laser source and welding head. The temperature control sensor uses imported brands.

6. Welding connection fiber

The 10-meter-long optical cable adopts an integrated design, effectively avoiding damage to the fiber and problems caused by moisture, greatly improving the service life of the laser components.

Advantages of optical fiber laser welding machine

●The integrated cabinet integrates the laser, chiller, software control, etc., and has unique advantages such as small footprint, easy movement, and strong functionality.

●The handheld welding head is equipped with 10m original optical fiber, which is flexible and convenient.

●Hand-held operation mode, equipped with a special welding nozzle, can achieve welding of any part of the workpiece at any angle.

● Matches a variety of laser sources, is suitable for workpieces with various process requirements, and is welded into shape in one go with basically no deformation, meeting high-quality product requirements.

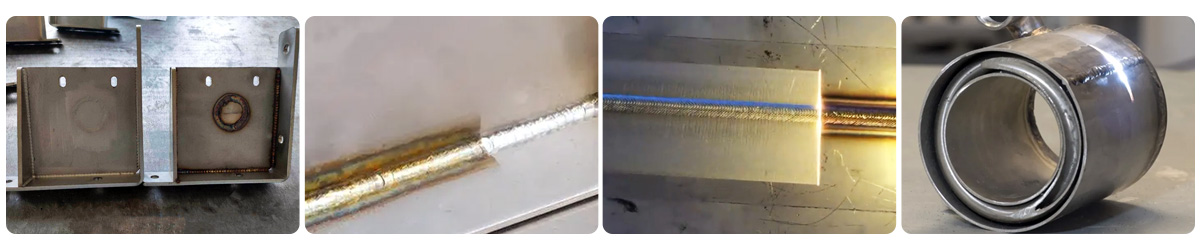

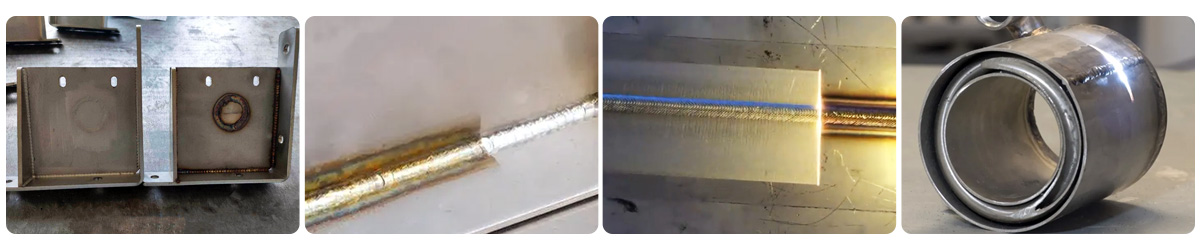

●The welds are beautiful, no weld scars, no discoloration, and no subsequent polishing is required.

●Welding is firm, and the strength of the weld reaches or even exceeds the base material itself.

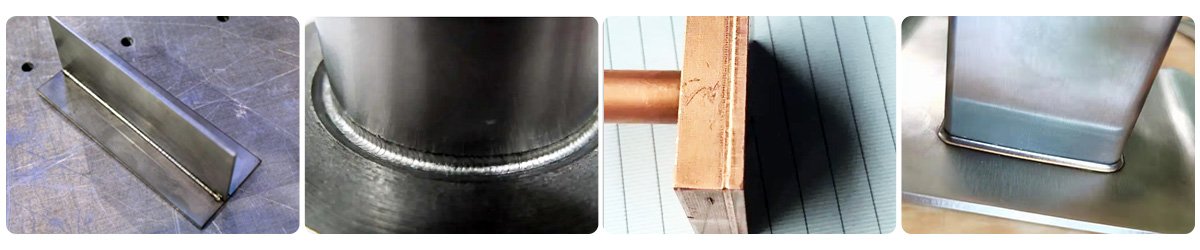

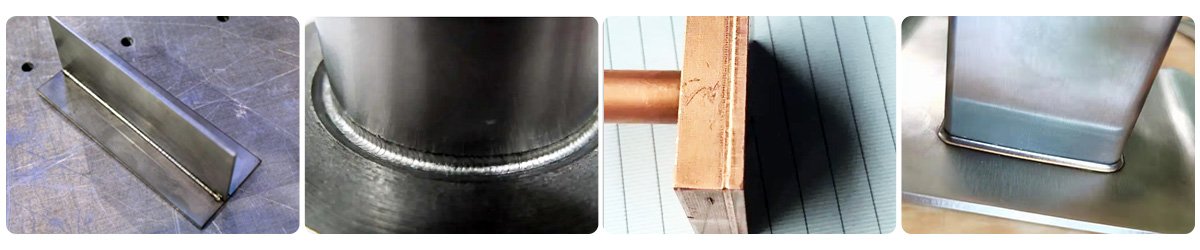

●Suitable for tailor welding, stack welding, internal and external fillet welding, arc welding, irregular shape welding, etc.

●The entire set of equipment is highly functional, meets ergonomic design, and is suitable for various working environment scenarios.

●The operation is simple, easy to learn and quick to use, the operator's technical threshold is not high, and it saves labor costs.

Single side weld thickness

Maximum melting | 1500W | 2000W | 3000W |

Stainless steel (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Mild steel (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Aluminum (mm) | 0.5-3 | 0.5-4 | 0.5-5 |

Brass/copper (mm) | 0.5-2 | 0.5-2.5 | 0.5-3 |

Galvanized sheet (mm) | 0.5-4 | 0.5-5/6 | 0.5-6/7 |

Iron (mm) | 0.5-4 | 0.5-6 | 0.5-7/8 |

Remark: Double weld thickness can be achieved if the material is welded from both sides in two times.

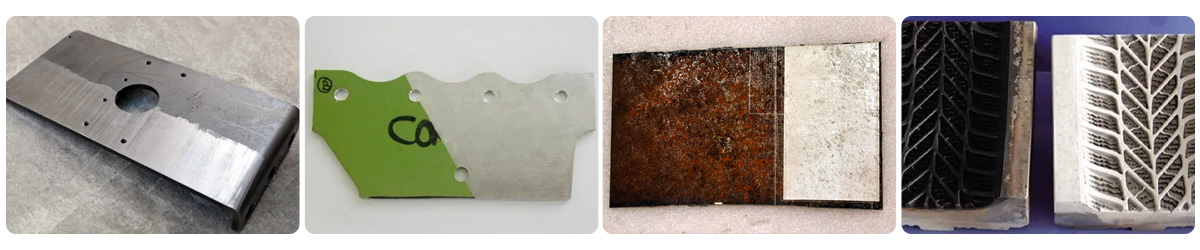

The main use of handheld fiber laser welding machine

1. Welding

The main purpose of a laser welding machine is undoubtedly welding. It can weld almost all metal materials and can perform welding in various complex environments. It has high production efficiency and has more advantages compared to traditional processes such as argon arc welding and electric welding. When welding, it has higher production efficiency and more obvious advantages compared to traditional processes such as argon arc welding and electric welding. Using a laser welding machine, the weld seam width is small, the depth is large, the heat-affected zone is small, the deformation is small, the weld seam is smooth and beautiful, the welding quality is high, there are no pores, it can be precisely controlled, the welding quality is stable, and no post-weld treatment or simple treatment is required.

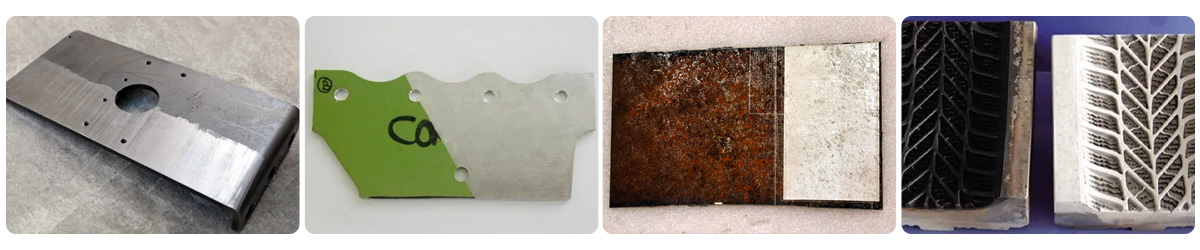

2. Cleaning

With the continuous reform and upgrading of laser welding machines, they have more and more functions. They can not only weld and cut, but also clean and remove rust. Laser welding machines use laser beams to eliminate the contamination layer on the surface of the processed workpiece. Cleaning with a laser welding machine has the advantage of being non-contact and does not require cleaning fluid, which can replace professional cleaning equipment.

3. Cutting

Laser cutting is a new type of cutting method. Using a laser welding machine, it can cut stainless steel, carbon steel, aluminum, aluminum alloy, iron, and other metal sheets, with a maximum cutting thickness of about 2mm.

4. Weld seam cleaning

In addition to the above three functions, our laser welding machine can also clean weld seams. Laser cleaning can effectively remove impurities such as oxides, welding slag, oil stains, and dust generated during the welding process, making the weld seam surface clean. This not only helps improve the quality of the weld seam but also enhances its strength and appearance. Laser cleaning has high precision and controllability, and can thoroughly clean the surface of the weld seam without damaging the base material.

Application materials

Suitable for stainless steel, carbon steel, copper, aluminum, gold, silver, chromium, nickel, titanium and many other metals and alloys; also can be used for welding between a variety of dissimilar materials.

Application industry

Suitable for all kinds of sheet metal, moulds, chassis, power distribution cabinets, kitchen and bathroom products, all kinds of hardware lighting, advertising signs, door and window frames, handicrafts, household products, food machinery, medical equipment, auto parts and other industries.

Parameters of optical fiber laser welding machine

Model | ST-FW1500H | ST-FW2000H | ST-FW3000H |

Power | 1500W | 2000W | 3000W |

Beam quality | ≤1.2 M⊃2; | ≤1.3 M⊃2; | ≤1.5 M⊃2; |

Laser wavelength | 1080nm |

Light exit mode | QCW /PWM /CW |

Max modulation frequency | 1000HZ |

Output power stability | <3% |

Aiming positioning system | Built-in Red Light |

Terminal type | QBH |

Delivery cable length | 10M (can be customized) |

Power supply | AC220V±10%, 50/60Hz |

Cooling system | Water Cooled with automatic pumping function |

working environment | Temperature 5-45°C /humidity 10-90% |

Applicable material | Almost all metal materials such as carbon steel, stainless steel, aluminum, brass and galvanized sheet. |

Net weight/gross weight | 140KG/170KG | 220KG/260KG | 270KG/320KG |

Machine size | 1000*500*1000mm | 1500*850*980mm | 1500*850*980mm |