Details Product Parameters Samples Video

Features of handheld laser cleaning machine for rust removal

1. Flexible and easy to operate, can meet multi-angle, precise position, precise size selective cleaning.

2. Equipped with 10m imported optical fiber, it can be very flexible and convenient for outdoor and long-distance cleaning.

3. Low operation cost, stable operation of laser cleaning system, low maintenance.

4. No chemical pollution, no cleaning agent residue, will not cause damage to the surface of the object and cause secondary pollution.

5. Long-term stable use, low operating costs, fast, efficient, time-saving, long-term costs are lower than traditional cleaning methods.

Details of handheld laser cleaning machine for rust removal

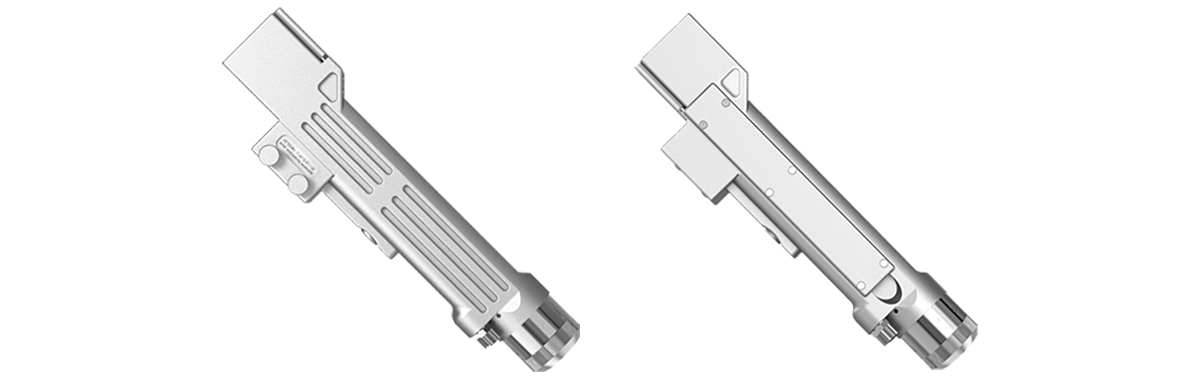

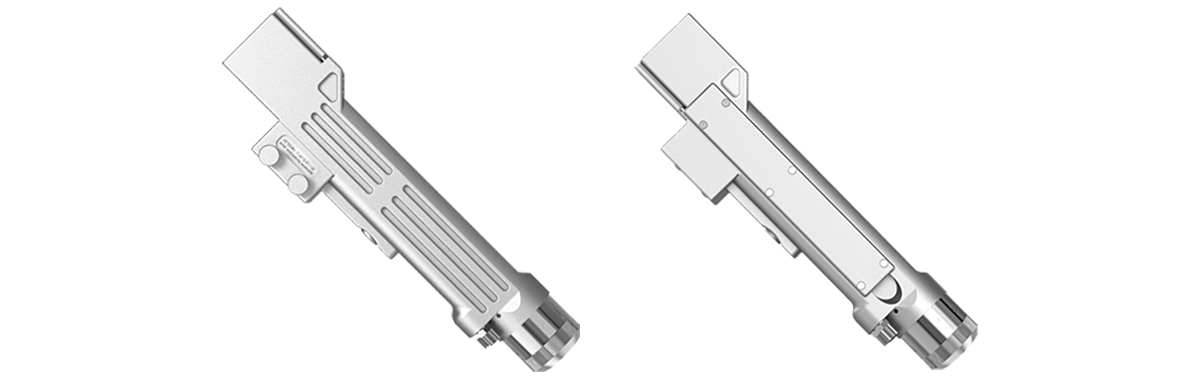

1. Laser cleaning head

Weighing only 0.7kg, it is compact and convenient to clean any shape of metal parts with a wide cleaning width of up to 300mm and equipped with a safety monitoring system.

2.Intelligent operation interface

Advanced resistive touch screen with higher sensitivity and intelligent control, supporting multiple languages (English, Spanish, German, Italian, French, Russian, Turkish, etc.)

3. Laser source

We use a custom 45UM core diameter clean fiber laser with a lifetime of 100,000 hours and no maintenance included.

4. Water Cooler

Double circulation water cooling can make the laser source and cleaning head more cool, temperature control sensor using imported brands.

5. Cleaning connection fiber

The cable distance from the laser cleaning head to the machine is 10 meters, so there is no need to move the machine when laser welding workpiece.

6.Large cleaning area

The maximum cleaning area is 300*300mm with high efficiency.

Advantages of handheld laser cleaning machine for rust removal

1. Wide range of applications: laser cleaning can remove all types of pollutants from the surface of various materials to achieve a cleanliness that can not be achieved by conventional cleaning. And also can selectively clean the surface of the material without damaging the material surface contaminants.

2. Operation safety: with multiple safety alarm functions, high security, to ensure the absolute safety of the operator during work.

3. Good cleaning effect: non-abrasive and non-contact, no thermal effect, no mechanical force on the cleaned object, no damage to the surface of the cleaned object.

4. Green and environmental protection: No need to use any chemical and cleaning liquid, the cleaning down waste is basically solid powder, small size, easy to store, recyclable, no photochemical reaction, no pollution.

5. Low cost: the initial investment is high, but it can be used steadily for a long time, with a service life of up to 10 years, low running cost, fast, high efficiency, time saving, and can soon get a return on investment.

Cleaning ability (only for reference)

Cleaning surface | 1000W | 1500W | 2000W |

Floating embroidery (20um) | 10m³/h | 15m³/h | 20m³/h |

Paint (120um) | 4m³/h | 6m³/h | 8m³/h |

Rusting (100um) | 2.5m³/h | 4m³/h | 5m³/h |

Handheld cleaning head

● High cleaning cleanliness, big welding width up to 300mm.

● Precise positioning and cleaning, weight only 0.7KG, easy to hand it.

● Non-contact material when cleaning that can protect the material.

● Effectively remove micron-sized particles.

● Environment friendly, no consumables.

Handheld laser cleaning machine for rust removal safety features

ST-FC1000H/1500H/2000H is a Class IV laser system and routine precautions are required for the safe operation of the equipment.

Built-in features include:

● Key switch control of laser source and Emergency-stop button ensure deliberate operation.

● Fiber laser interlock verifies integrity of laser delivery to the cleaning gun.

● Laser clean gun trigger, enable and then fire, for intentional operation(Double pulling the trigger before the light comes out).

Handheld laser cleaning machine for rust removal application

Application materials

Suitable for removing resin, paint, oil stains, stains, dirt, rust, coatings, etc. from the surface of objects.

Application industry

It is widely used in various industries such as the ship industry, automobile accessories, precision parts, molds, high -end machine tools, military equipment, building exterior walls, cultural relics protection, track, environmental protection industry and other industries.

Parameters of handheld laser cleaning machine for rust removal

Model | ST-FC1000H | ST-FC1500H | ST-FC2000H |

Power | 1000W | 1500W | 2000W |

Power consumption | 3000W | 4500W | 6000W |

Max. cleaning width | 170*170mm | 250*250mm | 300*300mm |

Laser wavelength | 1064nm |

Operation mode | Handheld |

Power adjustment range (%) | 10-100 (Gradient adjustable) |

Cleaning head weight | 0.7Kg |

Delivery cable length | 10M (can be customized) |

Input power | 220V±10% 50-60HZ |

Cooling system | Water Cooled with automatic pumping function |

Machine weight | 220KG | 230KG | 280KG |

Machine size | 935*720*1248mm | 1500*880*1160mm |