Welding wire is used as a filler metal or as a wire welding material for electrical conductivity. In gas welding and gas tungsten arc welding, the welding wire is used as filler metal; in submerged arc welding, electroslag welding and other MIG arc welding, the welding wire is both filler metal and conductive electrode. The surface of the welding wire is not coated with anti-oxidation flux.

Types of welding wire: stainless steel welding wire, aluminum welding wire, copper welding wire

Wire diameter range: 0.8mm, 1.0mm, 1.2mm, 1.6mm. 2.0mm

You can choose different types and diameters of welding wire according to the welding material and thickness.

It is compatible with the welding wire of the traditional MIG welding machine

Features of laser welding wire

1) For the welding of various steel materials, it has strong adaptability, and it is very convenient and easy to adjust the composition and proportion of the flux, and can provide the required chemical composition of the weld.

2) The process performance is good, and the welding seam is beautifully formed. Combined protection with gas slag is used to obtain good forming. The arc stabilizer is added to stabilize the arc and the droplet transfer is uniform.

3) Fast deposition speed and high production efficiency Under the same welding current, the flux-cored wire has high current density and fast melting speed. The deposition rate is about 85%-90%, and the productivity is about 3-5 times higher than that of electrode arc welding.

4) Larger welding current can be used for all-position welding.

Advantages of laser welding wire

1. High-quality raw materials and advanced technology, good welding performance, time-saving and labor-saving, and strong adaptability to welding of various metals.

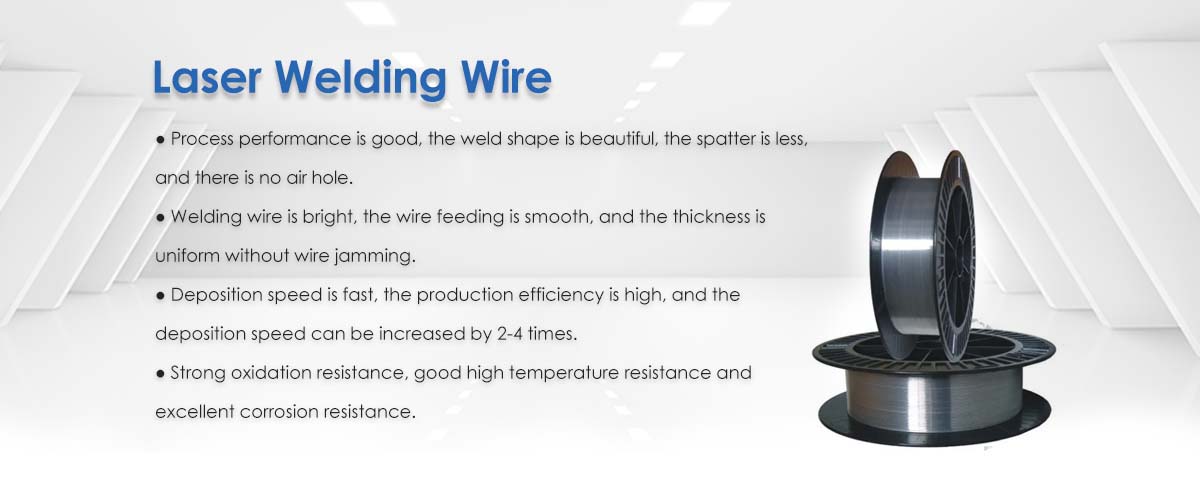

2. The process performance is good, the weld shape is beautiful, the spatter is less, and there is no air hole.

3. The welding wire is bright, the wire feeding is smooth, and the thickness is uniform without wire jamming.

4. The deposition speed is fast, the production efficiency is high, and the deposition speed can be increased by 2-4 times.

5. Strong oxidation resistance, good high temperature resistance and excellent corrosion resistance.

Precautions of laser welding wire

1. The warehouse where welding wire is stored should have a dry and ventilated environment to avoid moisture; water, acid, alkali and other liquids that are highly volatile and corrosive substances should not exist, and it is not suitable to coexist with these substances in the same warehouse.

2. The welding wire should be placed on the wooden pallet, it cannot be placed directly on the floor or close to the wall.

3. Be careful not to break the packaging, especially the inner packaging "heat shrinkable film" when storing and handling welding wire.

4. Open the welding wire package and use it up as soon as possible. Once the welding wire is directly exposed to the air, its anti-rust time will be greatly shortened (especially in a humid and corrosive medium environment).

5. Distribute welding wire according to the principle of "first in, first out" to minimize product inventory time.

6. Please store according to the category and specification of welding wire to prevent misuse.