Features of Laser protection lens

1. High energy absorption: Laser protective lenses can efficiently absorb laser energy and convert it into heat energy, thereby reducing or blocking the penetration of laser radiation.

2. High transmittance: Laser protection lenses can block and absorb lasers of specific wavelengths while maintaining a high visible light transmittance to ensure the operator's visual observation and work efficiency.

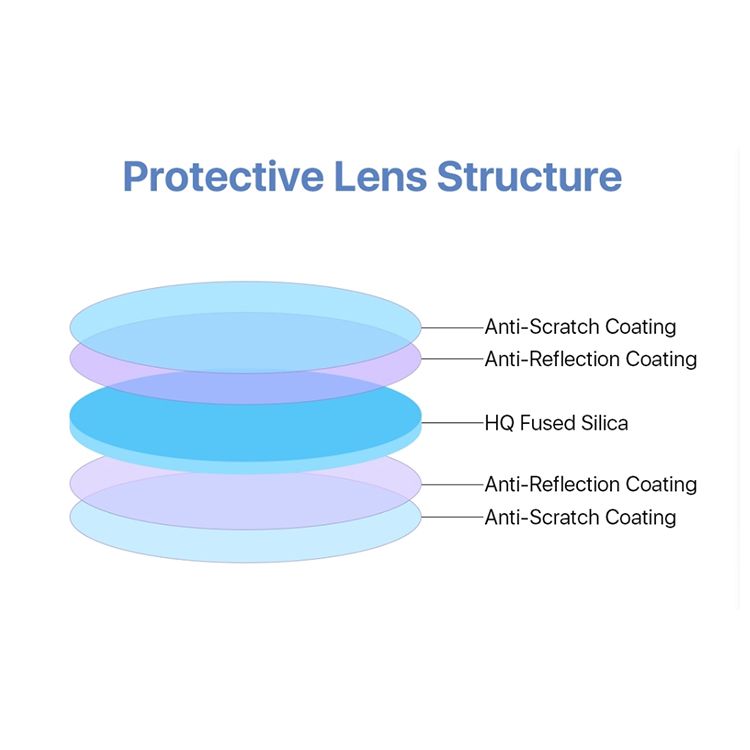

3. Anti-scratch and chemical resistance: Laser protective lenses are usually made of high-hardness and corrosion-resistant materials, which can resist scratches and chemical corrosion and extend their service life.

4. Multi-layer coating: Laser protective lenses often use multi-layer optical coating technology to enhance its ability to reflect and transmit laser light and improve the protection effect.

Main effect of Laser protection lens

Protect the focusing lens to prevent splashes from splashing onto the lens and causing damage to the lens. Ensure the processing accuracy requirements by regularly replacing the protective lens. Coating the lens with a 1064nm anti-reflection coating with a high damage threshold (>15J/cm2) can effectively increase the transmittance of the lens, reduce energy loss, and improve the quality of processed products.

1. Protective function

Protective lenses can effectively prevent external dust, dirt and other impurities from entering the laser, keep the surface of the lens clean, so as to ensure the quality and stability of the laser output.

2. Improvement of transmittance

Good protective lenses have high transmittance, which can reduce the reflection and scattering of the beam and improve the working efficiency of the laser.

3. Anti-wear function

The protective lenses are specially treated to have certain anti-wear performance, which can prolong the service life of the lenses and reduce the replacement frequency and maintenance cost.

4. Beam adjustment

Some protective lenses also have the function of adjusting the beam, which can change the angle and shape of the beam to meet different working requirements and improve the precision of laser processing.

5. Thermal stability

High-quality protective lenses have good thermal stability, which can maintain stable optical performance under high temperature environment and ensure stable operation of the laser for a long time.

6. Anti-reflective coating

Some protective lenses are coated with special anti-reflective coating, which reduces the reflection loss of the beam, improves the optical transmission efficiency and enhances the output power of the laser.

Protective lenses for laser equipment are an important part of ensuring the normal operation and extended service life of laser equipment. Correct protective lenses can effectively reduce the loss of the laser beam and improve the stability and efficiency of the equipment.

1. Regular cleaning of lenses

Dust and dirt on the surface of the lens will affect the transmission effect of the laser beam, so it is crucial to clean the lens regularly. Use special lens cleaning tools and cleaning solution, gently wipe the lens surface to avoid scratches.

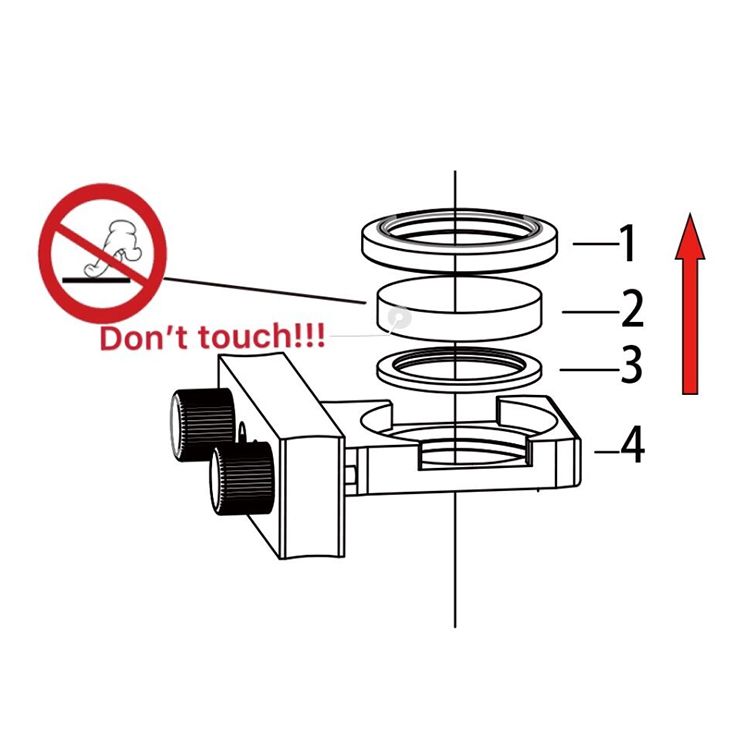

2. Avoid collision and damage

Laser equipment lenses are often very fragile, avoid collision and fall, so as not to cause damage to the lens. When replacing the lenses, operate gently to ensure proper installation.

3. Regularly check the condition of the lenses

Regularly check the condition of the lenses, including whether there are scratches, cracks or other damage. If problems are found, replace the lenses in time to ensure the normal operation of the equipment.

4. Lens maintenance and replacement

Regularly maintain the lenses to extend their service life. When the lens aging or damage can not be repaired, timely replacement of new lenses to ensure the normal operation of the equipment.

5. Seek professional help

For the maintenance and replacement of protective lenses of laser equipment, you can seek professional help if you encounter problems. Professional technicians can provide more accurate diagnosis and solutions to ensure the safe and stable operation of the equipment.

Application of Laser protection lens

● Laser cutting, optical fiber protection sheet, laser dust-proof lens

● Laser welding, material processing, optical fiber protection sheet, laser dust-proof lens

● Laser marking

● Laser transmission or laser blocking

UV fused silica windows are very suitable for fiber cutting machines, UV lithography technology, marking machines and other laser light sources and high-power lasers.

● Lens protection