Laser cutting nozzle description

Laser cutting nozzle is one of the most important parts in laser cutting. The nozzle is located at the lower end of the cutting head. Both the laser beam and the auxiliary gas act on the cutting material through the nozzle. Its main function is to gather the auxiliary gas and form a high pressure, release it to the surface of the cutting material and the slit, and blow away the cutting process. The resulting molten and vaporized base metal leaves a clean slit; at the same time, it prevents slag, smoke and other pollutants from bouncing upwards, thereby protecting the internal lens.

Features of laser cutting nozzles

● Imported copper material: Different from ordinary red copper and brass, imported copper material is used, which has high sensitivity, high hardness and slag resistance, and is solid and durable.

● Complete specifications: complete types and models.

● Seiko production: Strict oxidation process, bright and durable copper color, effectively prolonging the use time, improving cutting efficiency and quality.

● High temperature resistance and less anti-slag: the product has high processing precision, fast cutting speed and long service life.

Types of laser cutting nozzles

Nozzles are divided into single-layer and double-layer nozzles.

● The single-layer nozzle has a relatively slow gas flow rate, and is often used to cut metals such as stainless steel, aluminum alloy, and copper, and nitrogen is often used as the auxiliary gas.

● The double-layer nozzle has a fast gas flow rate and is suitable for high-speed cutting. It is often used to cut carbon steel, and oxygen is generally used as an auxiliary gas.

Laser cutting nozzle size selection

The diameter of the nozzle determines the shape of the gas flow entering the incision, the gas diffusion area, and the gas flow rate, thereby affecting the removal of the melt and the stability of the cutting.

The air flow entering the incision is large, the speed is fast, and the position of the workpiece in the air flow is appropriate, the stronger the ability of the jet to remove the melt. The user selects the nozzle size according to the laser power used and the thickness of the metal sheet to be cut.

Theoretically, the thicker the plate, the larger the nozzle should be used, the greater the pressure of the proportional valve setting, the greater the flow rate, and only by ensuring the pressure can the normal section effect be cut.

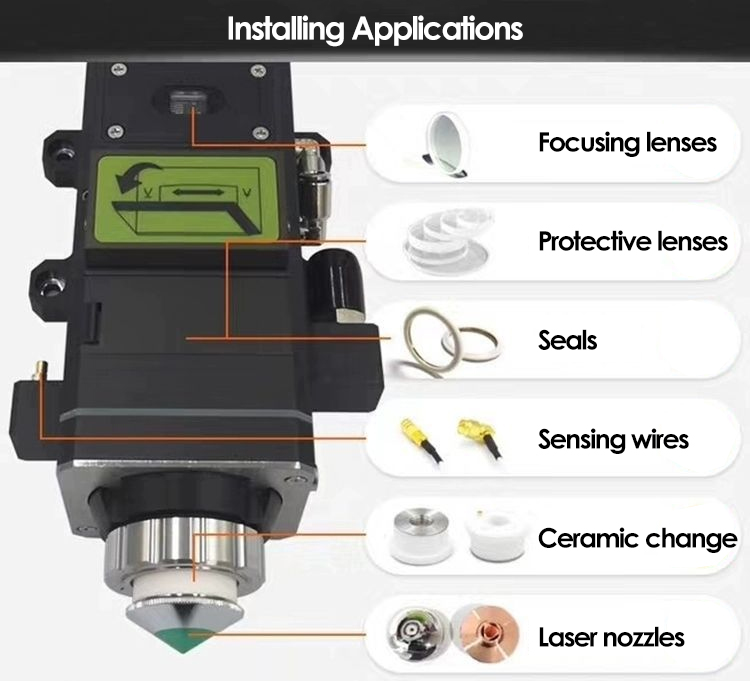

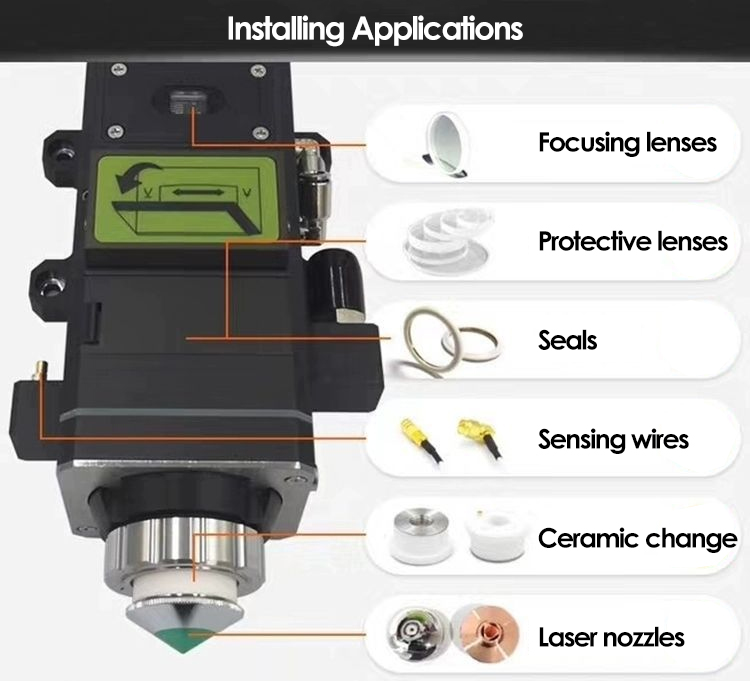

Installation application of laser cutting nozzle