The function of laser cutting nozzle

● Prevent debris such as melting stains from bouncing upwards, passing through the nozzle, and contaminating the focusing mirror;

● Control the gas diffusion area and size, so as to control the cutting quality.

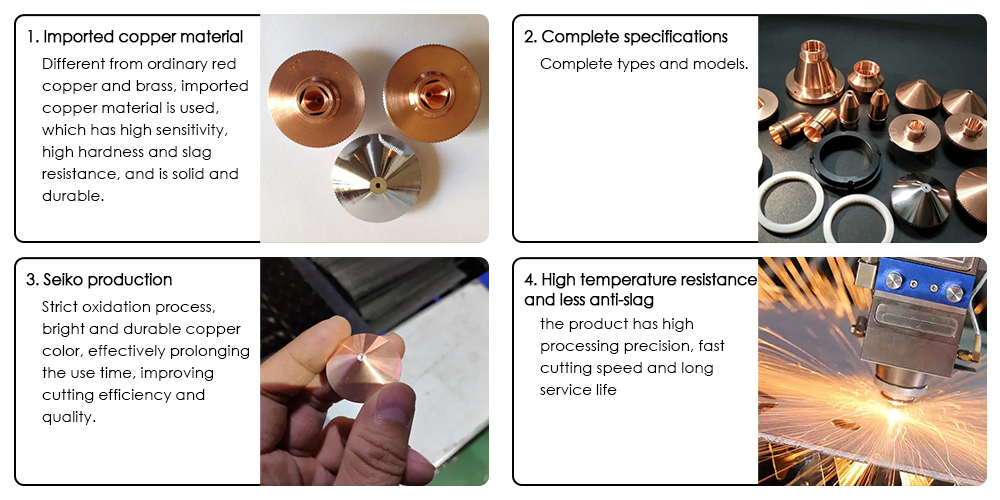

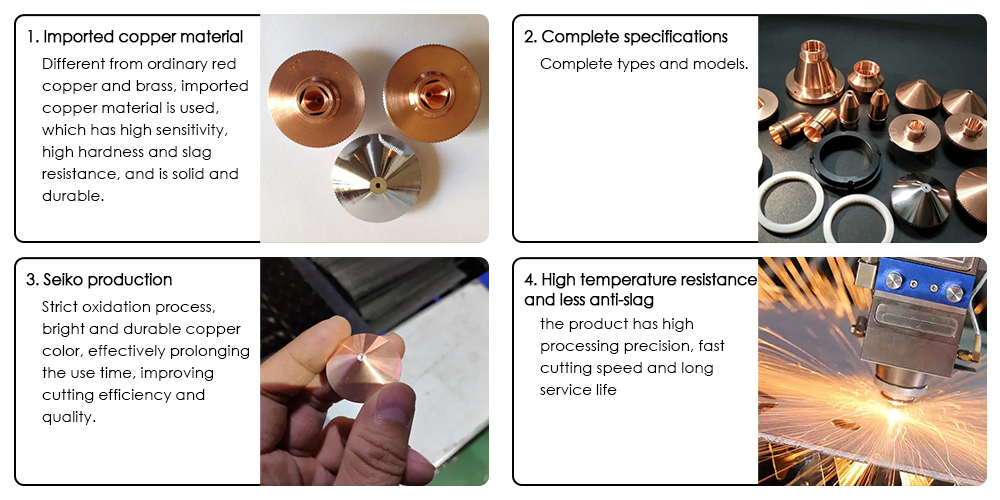

Features of laser cutting nozzles

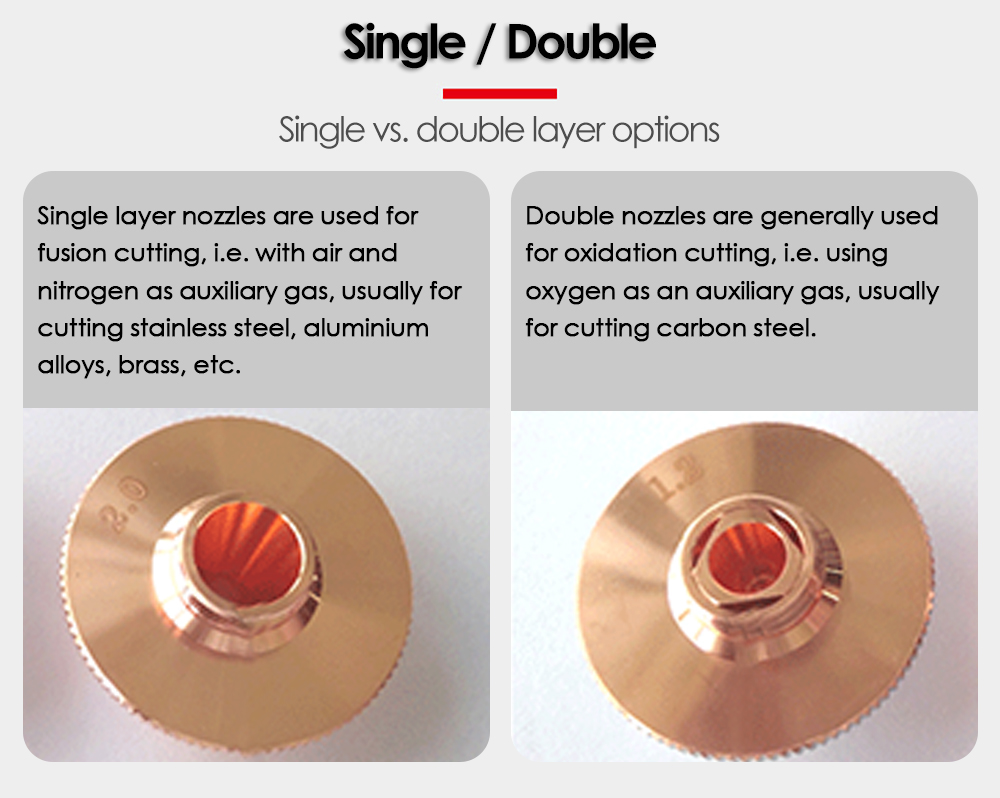

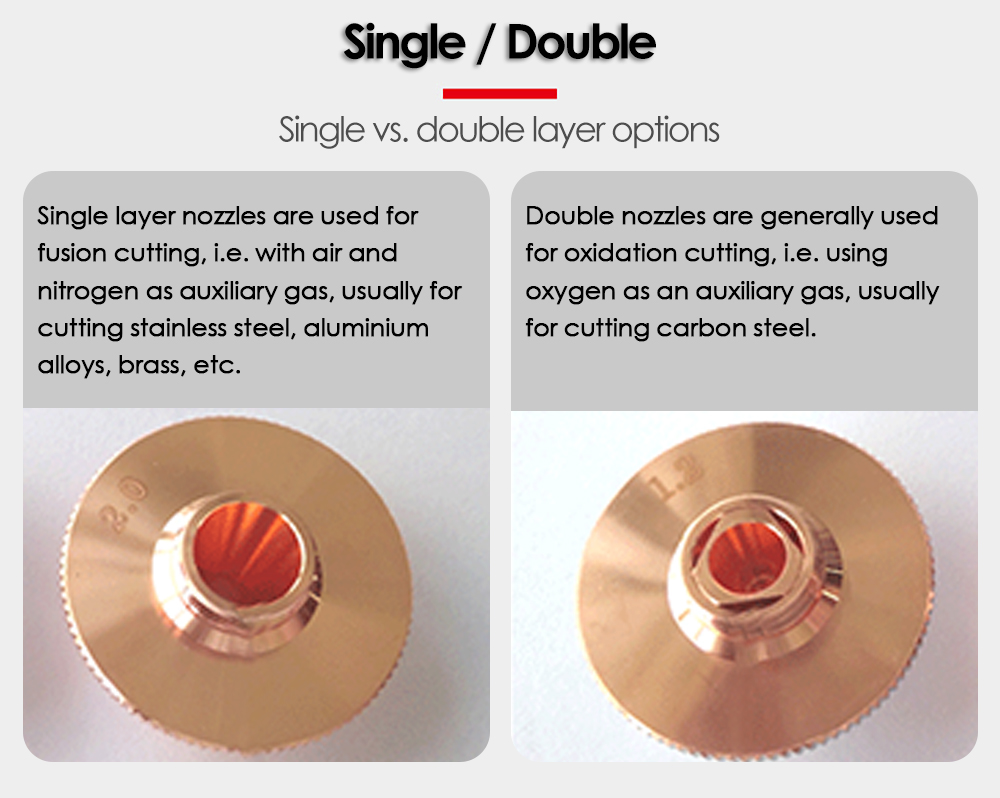

Types of laser cutting nozzles

Laser cutting nozzle selection

1. When cutting thin plates (below 3mm). A nozzle with an aperture of Φ1mm will be thinner, while a nozzle with an aperture of Φ1.5mm will be thicker, and the corners will be more prone to stains.

2. When cutting thick plates (above 3mm). The nozzle with Φ1mm aperture is not very stable when used. Because the cutting power is higher at this time, the relative heat dissipation time is longer, and the relative cutting time also increases accordingly. The gas diffusion area of the nozzle with Φ1mm aperture is small, so it is not stable, but basically it can still be used. The nozzle with Φ1.5mm aperture has a large gas diffusion area and a slow gas flow rate, so it is more stable during cutting

3. When cutting plates over 10mm. At present, nozzles with a diameter of 2 mm or more are generally selected.

As the aperture of the nozzle is larger, the protection effect on the focusing lens is smaller. Therefore, a reasonable choice of the size of the nozzle aperture of the laser cutting machine can produce more effectively.

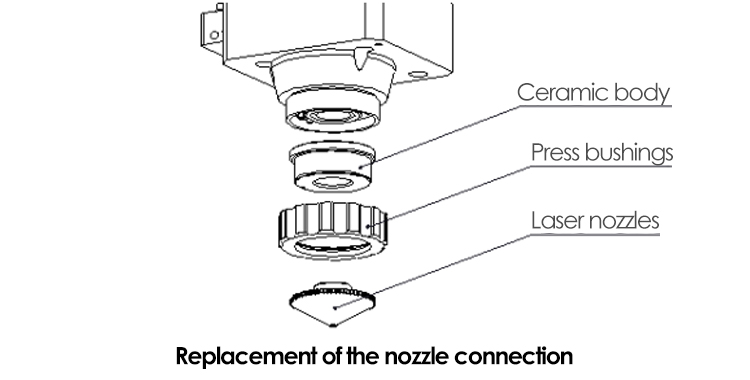

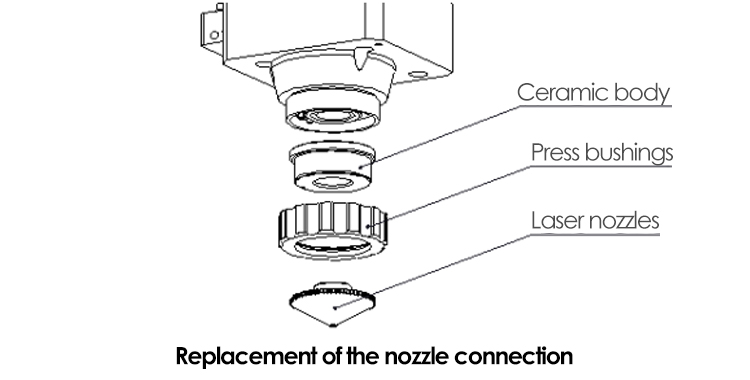

Laser cutting nozzle replacement

1. Unscrew the nozzle

2. Replace the nozzle with a new one and re-tighten it with appropriate force

3. After replacing the nozzle, the capacitance calibration must be done again.

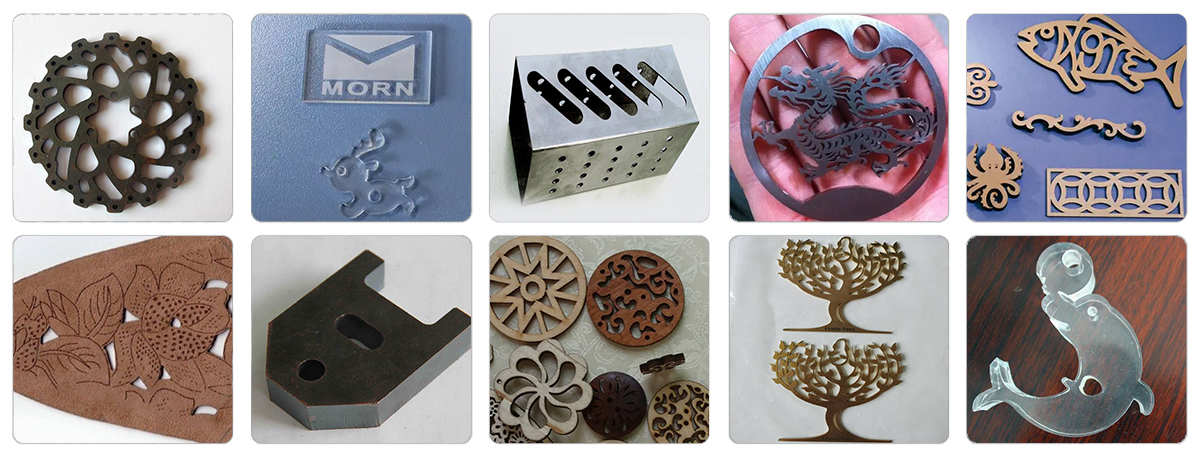

The scope of application of laser cutting nozzles

It can be used for 1064nm fiber laser (stainless steel, aluminum alloy, copper, carbon steel and other metal materials), and can also be used for Co2 laser (wood, acrylic, leather, plastic and other non-metal materials).