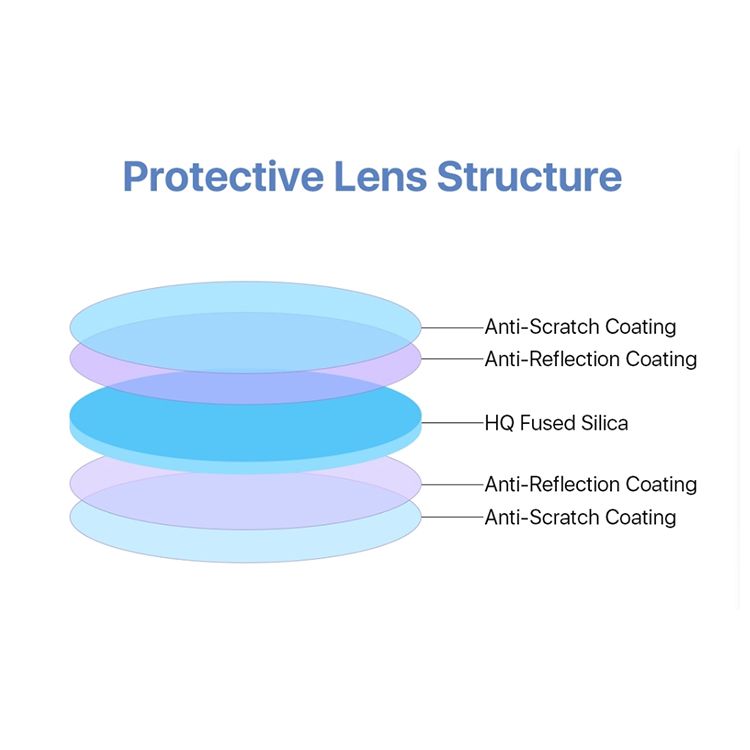

Protective lenses for laser equipment are an important part of ensuring the normal operation and extended service life of laser equipment. Correct protective lenses can effectively reduce the loss of the laser beam and improve the stability and efficiency of the equipment.

1. Regular cleaning of lenses

Dust and dirt on the surface of the lens will affect the transmission effect of the laser beam, so it is crucial to clean the lens regularly. Use special lens cleaning tools and cleaning solution, gently wipe the lens surface to avoid scratches.

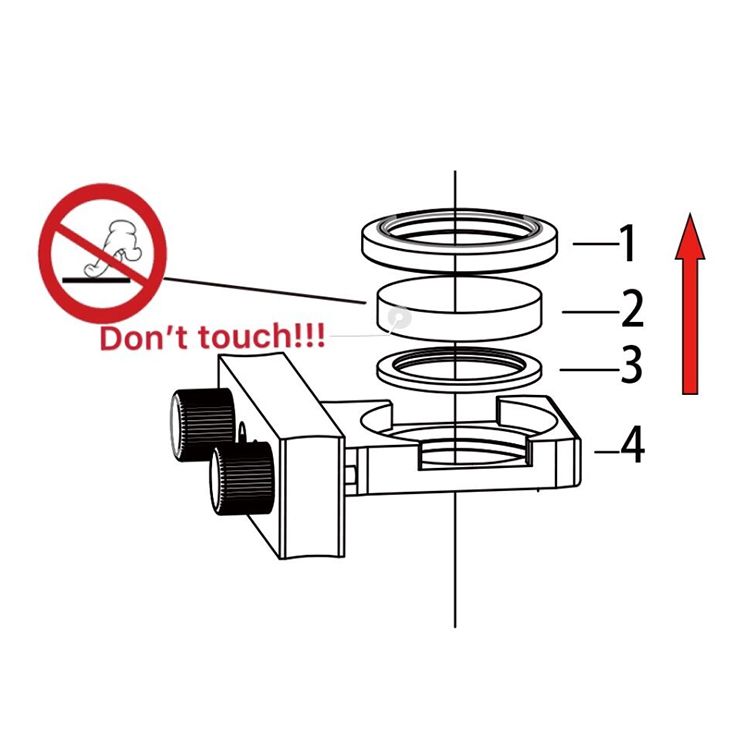

2. Avoid collision and damage

Laser equipment lenses are often very fragile, avoid collision and fall, so as not to cause damage to the lens. When replacing the lenses, operate gently to ensure proper installation.

3. Regularly check the condition of the lenses

Regularly check the condition of the lenses, including whether there are scratches, cracks or other damage. If problems are found, replace the lenses in time to ensure the normal operation of the equipment.

4. Lens maintenance and replacement

Regularly maintain the lenses to extend their service life. When the lens aging or damage can not be repaired, timely replacement of new lenses to ensure the normal operation of the equipment.

5. Seek professional help

For the maintenance and replacement of protective lenses of laser equipment, you can seek professional help if you encounter problems. Professional technicians can provide more accurate diagnosis and solutions to ensure the safe and stable operation of the equipment.